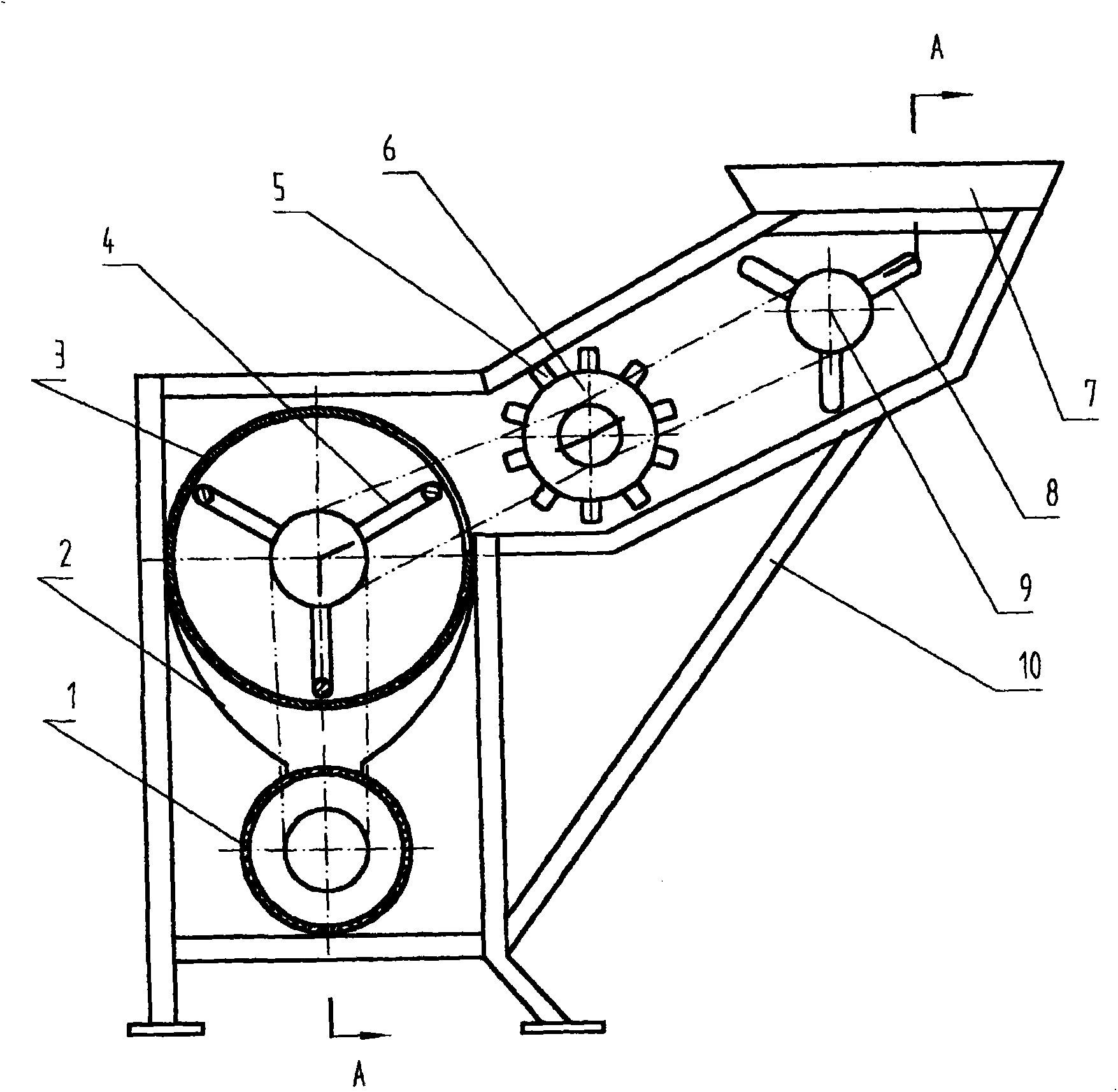

Watermelon seed extracting machine

A melon seed extractor and rack technology, which is applied in agricultural machinery and implements, solid separation, filter screens, etc., can solve the problems of high working vibration and noise, reduce machine efficiency, poor working reliability, etc. Low noise, long service life and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

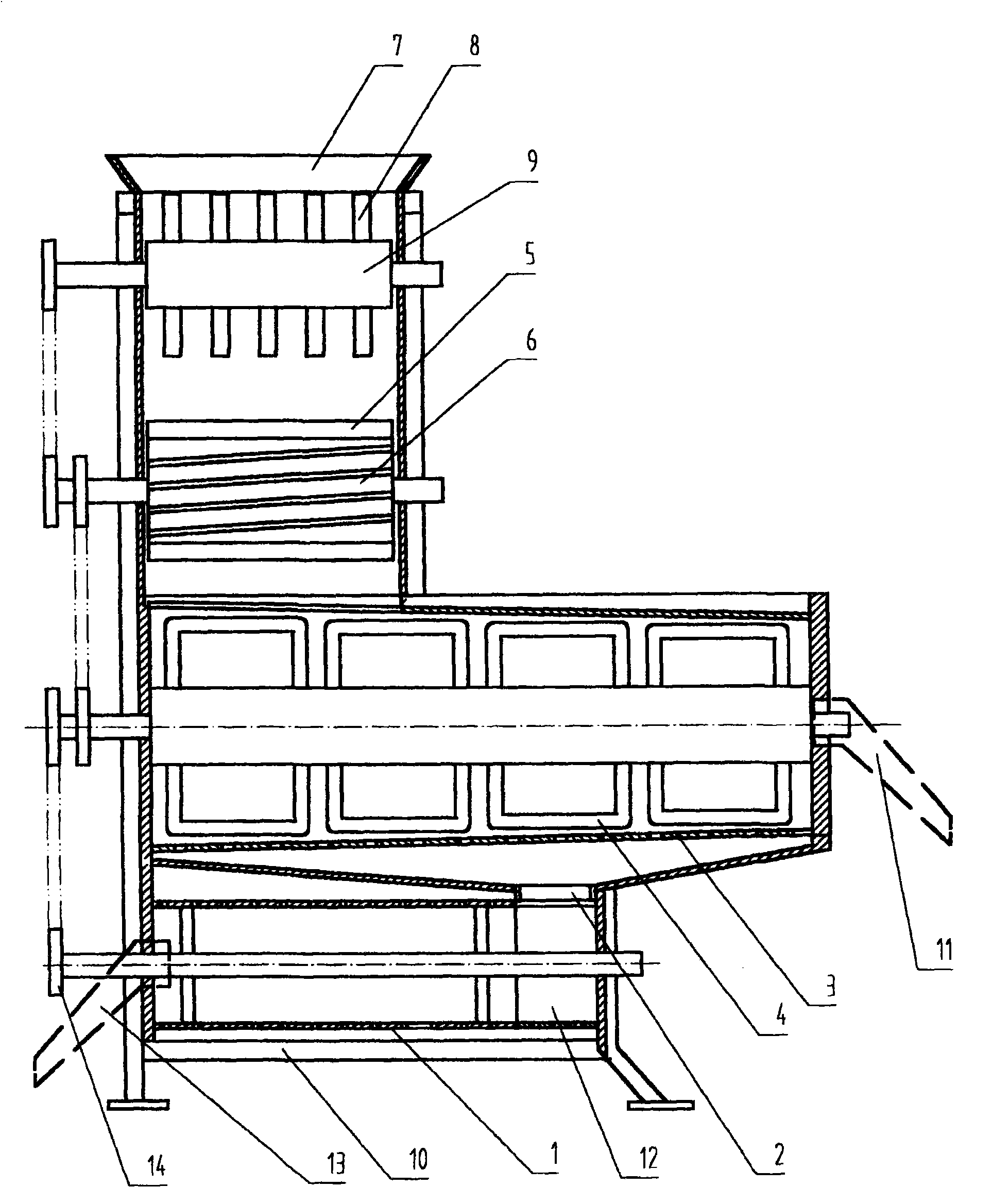

Embodiment 1

[0023] Embodiment 1: comprising frame, transmission mechanism, feeding hopper, crushing mechanism, seed outlet, crushing mechanism comprises delivery roller (9), and crushing tooth (8) is arranged on the delivery roller, is provided with rolling roller (6) behind the delivery roller ) There are horizontal rolling strips (5) on the wall of the rolling drum. The horizontal screen drum of the drum cleaning mechanism is a conical screen drum with a large discharge port at one end of the feed inlet and a small discharge port at the other end, including a horizontal screen with sieve holes. The sieve cylinder and the stirring propeller, the sieve holes are distributed in the lower part of the sieve cylinder, the stirring blade of the agitation propeller is in the shape of a rectangular frame, the head of the sieve cylinder is provided with a pulp discharge port, and the lower part of the sieve cylinder of the drum cleaning mechanism is equipped with a moving The selected trommel siev...

Embodiment 2

[0024] Embodiment 2: Compared with Embodiment 1, the difference of this embodiment is that the sieve cylinder of the cylinder cleaning mechanism is composed of a fixed sieve cylinder and a moving sieve cylinder, and a section at the feed inlet is a fixed sieve cylinder, and the sieve holes are distributed in On the whole screen cylinder, the stirring leaf on the shaft of the stirring propeller is in the shape of a rectangular plate.

Embodiment 3

[0025] Embodiment 3: Compared with Embodiment 1, the difference of this embodiment is that the cylinder wall of the selecting trommel is provided with agitation and propulsion sheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com