Fine-fraction low-grade barite separate beneficiation technology

A fine-grained, barite technology, which is applied in the field of beneficiation technology for graded recovery of barite, can solve the problems of low concentrate grade, high grinding cost, and high cost of chemical dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

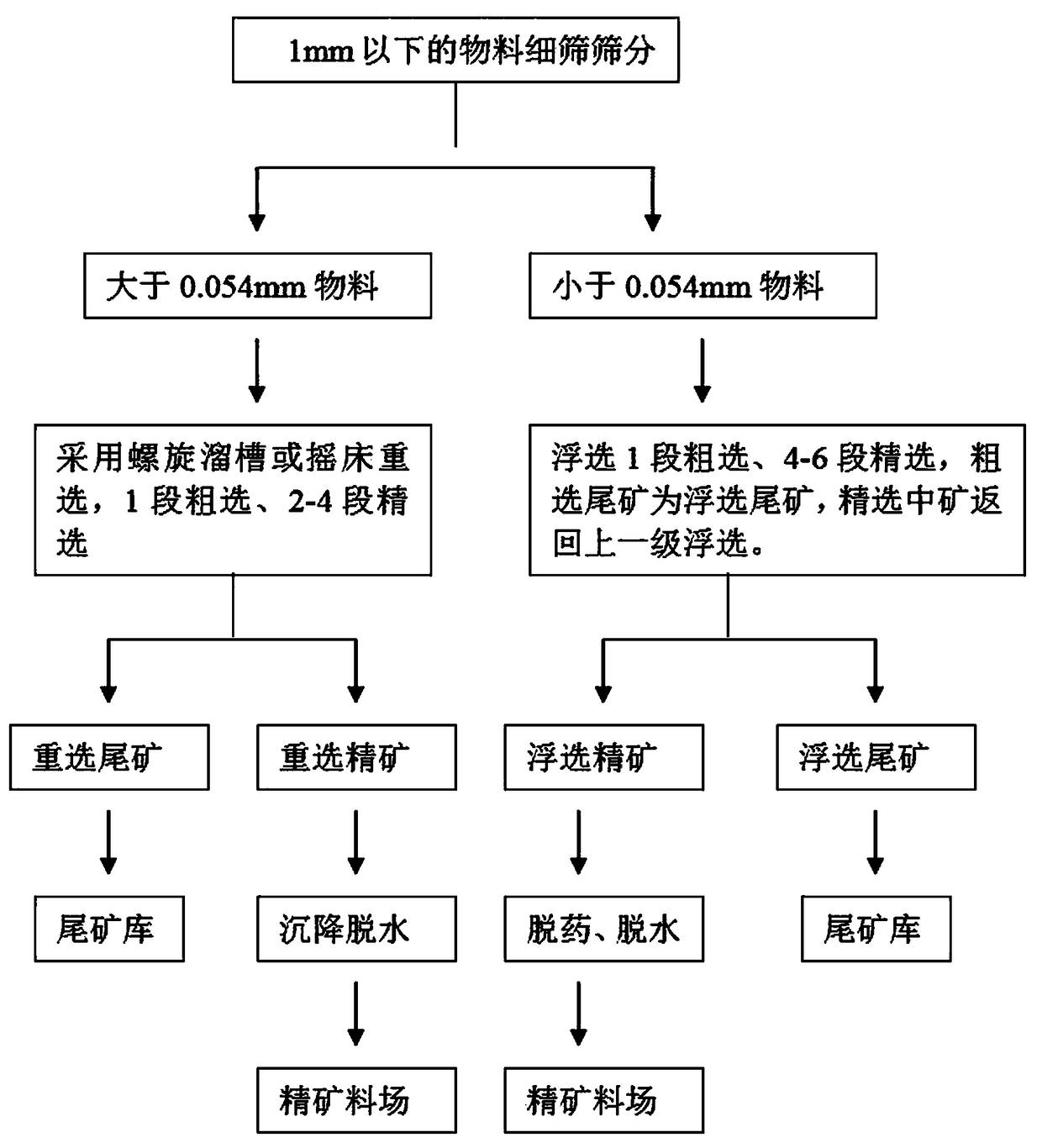

Method used

Image

Examples

Embodiment 1

[0031] 1# material BaSO 4 content of 17.01%, the material is classified by a standard sieve, and the content of the particle size greater than 0.054mm is 24.07%, BaSO 4 The content is 11.87%; the content of the particle size less than 0.054mm is 75.93%, BaSO 4 The content is 18.64%. Ore samples with particle size greater than 0.054mm are re-selected with a shaker, 1 stage of roughing and 3 stages of concentration, and the concentrate BaSO can be obtained 4 Content 90.53% test index. The flotation process is adopted for the particle size less than 0.054mm, and one stage of roughing and six stages of fine selection are carried out. The dispersant is water glass, and the barite flotation collector is Z-S2. Available flotation concentrate BaSO 4 Content 92.38%, tailings BaSO 4 The test index with a content of 3.40%.

Embodiment 2

[0033] 2# material BaSO 4 content of 13.71%, the material is classified by a standard sieve, and the content of the particle size greater than 0.054mm is 26.51%, BaSO 4 Content 9.60%; less than 0.054mm particle size content is 73.49%, BaSO 4 The content is 15.19%. Ore samples with particle size greater than 0.054mm are subjected to 1-stage roughing and 3-stage beneficiation on a shaking table to obtain concentrated ore BaSO 4 Content 90.33%, BaSO in tailings 4 Content 2.55% re-selection test index. The flotation process is adopted for the particle size less than 0.054mm. One stage of roughing and six stages of fine selection are carried out. The dispersant is water glass, and the barite flotation collector is Z-S2. Available flotation concentrate BaSO 4 Content 93.86%, tailings BaSO4 The test index with a content of 3.20%.

Embodiment 3

[0035] 3# material BaSO 4 content of 11.11%, the material is classified by a standard sieve, and the content of the particle size greater than 0.054mm is 28.42%, BaSO 4 Content 7.81%; less than 0.054mm particle size content is 71.58%, BaSO 4 The content is 12.42%. Ore samples with particle size greater than 0.054mm are subjected to 1-stage roughing and 3-stage beneficiation on a shaking table to obtain concentrated ore BaSO 4 The test index with a content of 89.36%. The flotation process is adopted for the particle size less than 0.054mm, and one stage of roughing and six stages of fine selection are carried out. The dispersant is water glass, and the barite flotation collector is Z-S2. Available flotation concentrate BaSO 4 Content 96.39%, tailings BaSO 4 The test index with a content of 2.89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com