Equipment combination for fine flake graphite flotation technology

A technology of fine flakes and equipment is applied in the field of graphite sorting and equipment combination of fine flake graphite flotation process, which can solve the problems of unfavorable separation of large flakes, low efficiency of flotation machine equipment, low grade of graphite concentrate, etc. To achieve the effect of good flotation effect, high grade and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

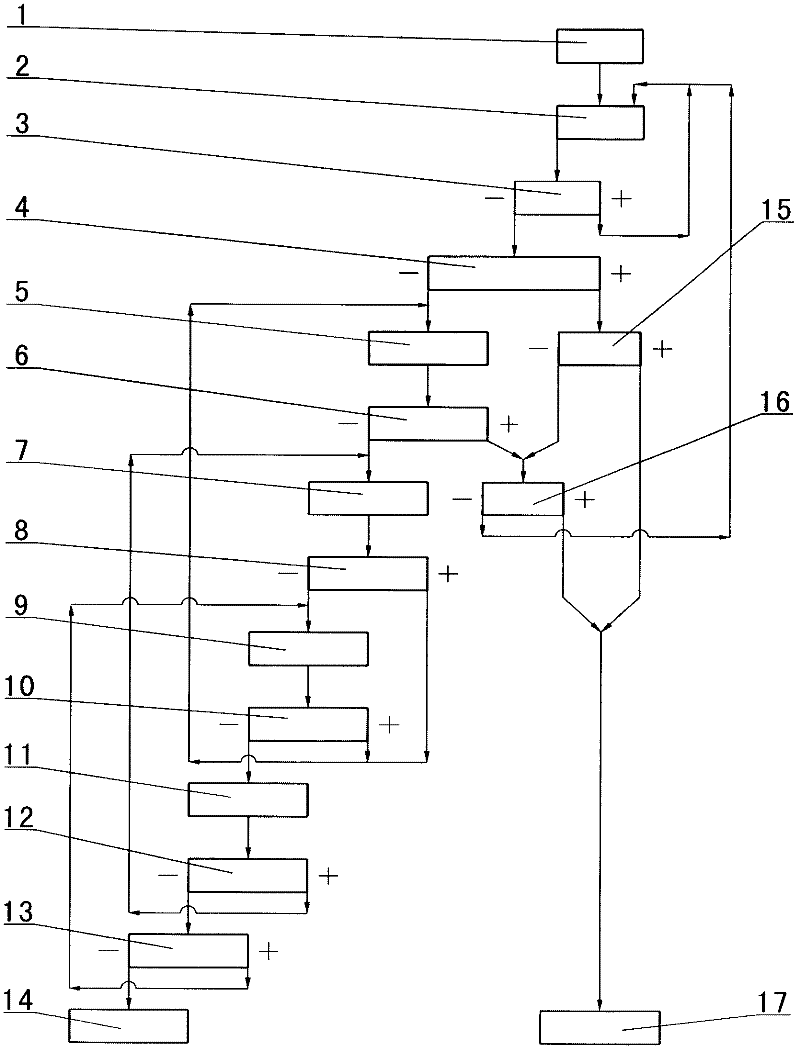

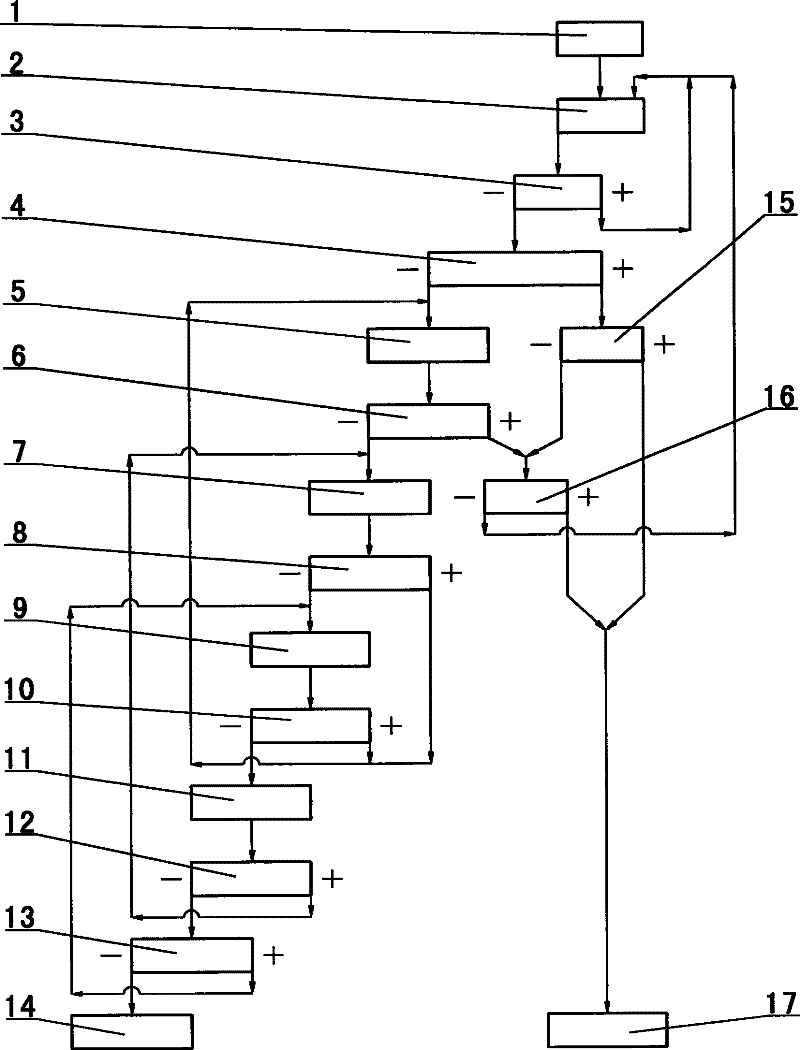

[0020] After the finely crushed graphite ore (1) is coarsely ground by the rod mill (2) and classified by the hydrocyclone (3), the coarse graphite pulp is returned to the rod mill (2) for regrinding, and the fine graphite pulp is put into flotation Coarse flotation in column I (4), the flotation concentrate flows to regrinder I (5) by itself and enters flotation column II (6) for flotation after regrinding, the flotation of flotation column I (4) Directly enter the flotation column VII (15) for sweeping. The flotation concentrate of the flotation column II (6) and the flotation concentrate of the flotation column VII (15) are swept by the flotation column VIII (16), and the flotation concentrate returns to the rod mill (2), The flotation tailings of the flotation columns VII (15) and VIII (16) directly enter the tailing pool (17). The flotation concentrate of the flotation column II (6) is re-grinded by the re-grinder II (7) and then enters the flotation of the flotation col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com