Beneficiation method for high-phosphor oolitic hematite

A technology of hematite and high-phosphorus oolites, applied in flotation, solid separation and other directions, can solve the problems of large acid consumption, low foam quality, and high cost, and achieve reduced return pressure, high foam quality, and reduced phosphorus content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

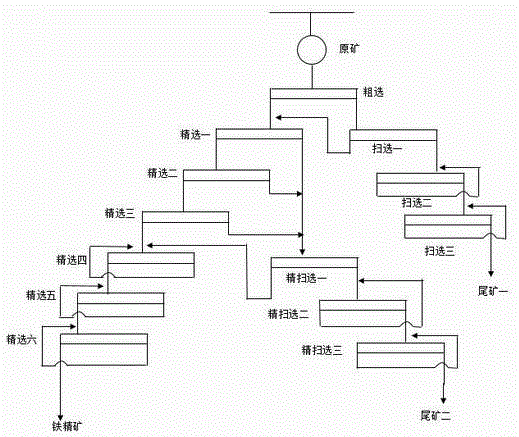

Image

Examples

Embodiment 1

[0032] A high-phosphorus oolitic hematite in Enshi contains as high as 0.52wt% phosphorus, and the main impurity minerals are silicates and a small amount of carbonates. Through phase analysis, the grade of iron is 43.30wt%, mainly composed of weak magnetic hematite, accounting for 93.69wt%, a small amount of strong magnetic mineral magnetite (1.14wt%) and extremely weak magnetic limonite ( 3.88wt%). The ore is crushed and ground until the hematite with a particle size of less than 0.074mm accounts for more than 95% of the whole hematite by mass, and 2000 g of sodium carbonate and water glass are added per ton of raw ore during grinding. After that, it enters the stirring and mixing stage. In the stirring stage, 1300 g / ton raw ore of sodium carbonate, 1300 g / ton raw ore of water glass, 2500 g / ton raw ore of corn starch and 600 g / ton of raw ore of mixed collector are added. Wherein, the composition and mass ratio of the mixed collector in this example are: oleic acid: dodecylo...

Embodiment 2

[0036] A high-phosphorus oolitic hematite in Ningxiang has a phosphorus content as high as 1.81wt%, and the main impurity minerals are silicates and a small amount of carbonates. Through phase analysis, the grade of iron is 46.44wt%, mainly composed of weak magnetic hematite, accounting for 95.38wt%, a small amount of strong magnetic mineral magnetite (1.02wt%) and extremely weak magnetic limonite ( 3.60wt%). The ore is crushed and ground until the hematite with a particle size of less than 0.074mm accounts for more than 95% of the whole hematite by mass, and 3000 g of sodium carbonate and water glass per ton of raw ore are added during the ore grinding. After that, it enters the stirring and slurrying stage. In the stirring stage, 1000 g / ton raw ore of sodium carbonate, 1000 g / ton raw ore of water glass, 2000 g / ton raw ore of corn starch and 600 g / ton of raw ore of mixed collector are added. Wherein, the composition and mass ratio of the mixed collector in this example are: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com