Method for producing xylose by sugarcane leaves

A sugarcane leaf and xylose technology, applied in the production of sugar, sugar production, application and other directions, can solve the problems of heavy environmental pollution, difficult biochemical treatment, etc., and achieve simple desalination, high production sugar extraction rate and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

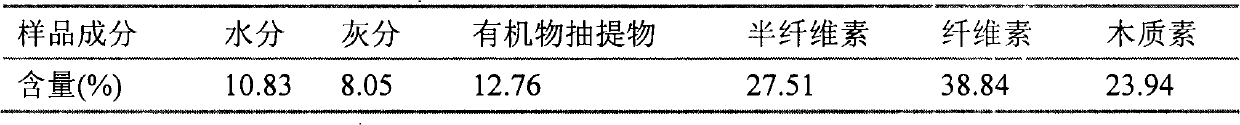

Method used

Image

Examples

Embodiment 1

[0024] (1) After washing the sugarcane leaves with clear water, dry and pulverize them into 60-mesh powder for subsequent use;

[0025] (2) Take 100 grams of sugarcane leaf powder and add 800 mL of dilute sulfuric acid with a mass percentage of 0.5% to fully mix, and then cook at 105 ° C for 0.3 h;

[0026] (3) After the pretreatment, the sugarcane leaf mixture was filtered, and the filtrate was discarded to obtain 88.3 grams of solid material, which was then fully mixed with 1068 mL of 1.5% dilute hydrochloric acid by mass percentage, and then digested and hydrolyzed in a cooking pot for 2 hours at 121° C.;

[0027] (4) After hydrolysis, 870 mL of the obtained hydrolyzate was filtered, decolorized and desalted three times, concentrated three times, powdered activated carbon was used for decolorization, 26.1 g of activated carbon was added, and the temperature was kept at 60°C for 60 minutes to decolorize the hydrolyzed solution, and anion and cation exchange resins were used f...

Embodiment 2

[0033] (1) After washing the sugarcane leaves with clear water, dry and pulverize them into 80-mesh powder for subsequent use;

[0034] (2) Take 100g of sugarcane leaf powder, add 1000mL of dilute sulfuric acid with a mass percentage of 0.1%, mix well, and then cook at 100°C for 0.6h;

[0035] (3) After the pretreatment, the sugarcane leaf mixture was filtered, and the filtrate was discarded to obtain 86.7 g of solid material, which was fully mixed with 688 mL of dilute hydrochloric acid with a mass percentage of 1.0%, and then digested and hydrolyzed in a cooking pot for 4 hours at 125° C.;

[0036] (4) After hydrolysis, 531 mL of the obtained hydrolyzate was filtered, decolorized and desalted three times, concentrated three times, powdered activated carbon was used for decolorization, 26.5 g of activated carbon was added, and the temperature was kept at 70 ° C for 30 minutes to decolorize the hydrolyzed solution, and anion and cation exchange resins were used for desalination...

Embodiment 3

[0042] (1) After washing the sugarcane leaves with clear water, dry and pulverize them into 100-mesh powder for subsequent use;

[0043] (2) Take 100g of sugarcane leaf powder, add 1200mL of dilute sulfuric acid with a mass percentage of 0.4%, mix thoroughly, and then cook at 90°C for 0.8h;

[0044] (3) After the pretreatment, the sugarcane leaf mixture was filtered, and the filtrate was discarded to obtain 82.3 g of solid material, which was fully mixed with 984 mL of dilute formic acid with a mass percentage of 7%, and then digested and hydrolyzed in a cooking pot for 5 hours at 110° C.;

[0045] (4) After hydrolysis, 836 mL of the obtained hydrolyzate was filtered, decolorized and desalted three times, concentrated three times, powdered activated carbon was used for decolorization, 50.1 g of activated carbon was added, and the temperature was kept at 80 °C for 40 minutes to decolorize the hydrolyzed solution, and anion and cation exchange resins were used for desalination. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com