Reduction and reclamation recycled water reuse zero emission treating technology

A treatment process and recycling technology, which is applied in the field of zero-discharge treatment process for water reduction and recycling of recycled water, can solve the problems of high investment, low anti-pollution, high energy consumption, etc., so as to reduce operating costs and reduce treatment Difficulty, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

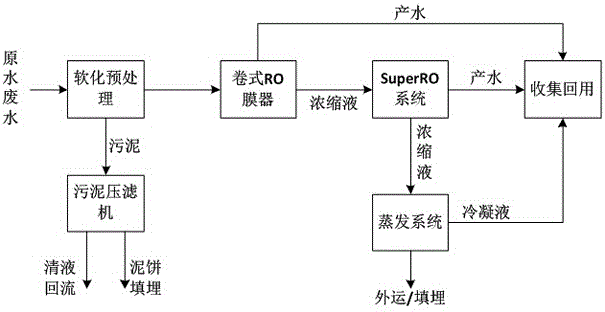

[0029] Such as figure 1 As shown, the zero-discharge treatment process for the reduction and recycling of reclaimed water includes the following steps:

[0030] (1) The raw water wastewater is softened and pretreated to achieve calcium and magnesium ion concentrations < 100mg / l, and total hardness < 200mg / l; the softening pretreatment includes some pre-membrane pretreatments such as acid addition, alkali addition, precipitation and pH callback. process, because the pretreatment here can be processed in a conventional manner, so it will not be described in detail in this embodiment. The sludge produced by it is solidified into a mud cake by a sludge filter press for landfill treatment, and the clear liquid produced by it is refluxed for pretreatment Reuse in process;

[0031] (2) The effluent enters the roll-type RO membrane device for the first separation and concentration to realize the first desalination treatment, and the produced water is collected and reused. The membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com