Recycled concrete and preparation method thereof

A technology of recycled concrete and recycled coarse aggregate, applied in the field of concrete, can solve the problems of unfavorable construction, poor fluidity, high water absorption rate of recycled aggregate, etc., and achieve the effects of convenient construction, improved fluidity and slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

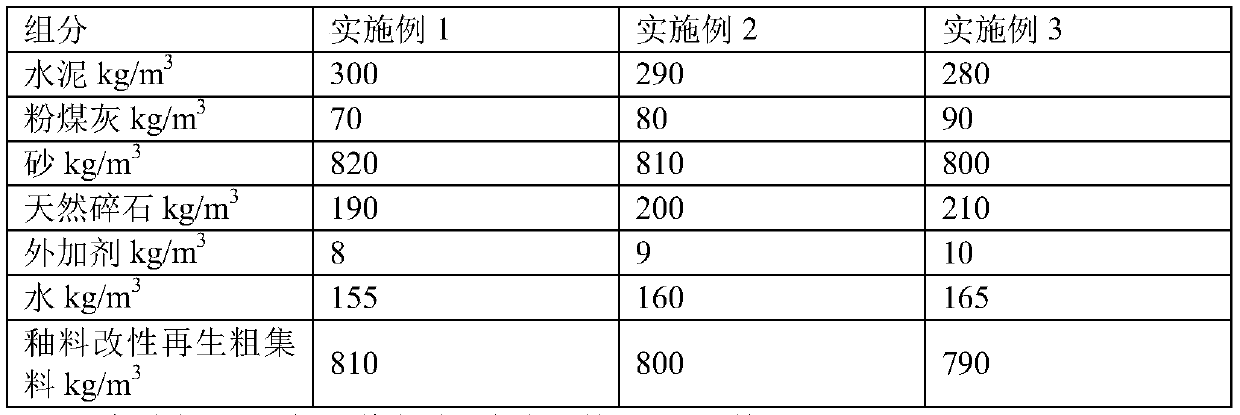

[0045] Embodiment 1: a kind of recycled concrete, each component of its raw material and corresponding parts by weight thereof are as shown in table 1,

[0046] The glaze modified recycled coarse aggregate is prepared through the following steps:

[0047] Step 1, crushing the waste concrete into coarse aggregates of 5-25 mm in size, washing the broken coarse aggregates with water, and drying them naturally to obtain regenerated coarse aggregates;

[0048] Step 2, prepare the glaze, put 5±1 parts of feldspar, 5±1 parts of quartz, 5±1 parts of calcite, 17±1 parts of kaolin, and 4±1 parts of alumina Grind in a ball mill for 20±0.5 hours, mix the ground raw materials evenly to obtain glaze;

[0049] Step 3, put the regenerated coarse aggregate into the mixing tank, add water to the glaze and stir evenly to obtain a glaze slurry, the parts by weight of the glaze, surfactant and water are 30 parts and 60 parts respectively, and add the glaze into the mixing tank Slurry until the r...

Embodiment 2-3

[0055] Embodiment 2-3: A kind of recycled concrete, the difference from Example 1 is that the components of its raw materials and their corresponding parts by weight are shown in Table 1, and the raw materials of the glaze slurry and their corresponding parts by weight The number is shown in Table 2, and the unit in Table 1 is kg / m 3 It is the unit of parts by weight of the raw materials required for the recycled concrete of the present invention.

[0056] Each raw material of recycled concrete and parts by weight thereof in table 1 embodiment 1-3

[0057]

[0058] Each raw material and parts by weight of glaze slurry in table 2 embodiment 1-3

[0059] components Example 1 Example 2 Example 3 glaze 30 40 38 water 60 55 55

Embodiment 4

[0060] Embodiment 4: A kind of recycled concrete, the difference from Example 1 is that in the step 3 of preparing the glaze modified recycled coarse aggregate, water and surfactant are added to the glaze, and the glaze slurry is obtained by stirring evenly. The parts by weight of surfactant is 18 parts. In this embodiment, the surfactant is sodium dodecylbenzenesulfonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com