Fiber strand aggregating device for air slide

An air trough and fiber technology, which is used in textiles and papermaking, continuous winding spinning machines, drafting equipment, etc., can solve the problems of low yarn strength, increased yarn hairiness, and insufficient fiber alignment. Soft touch, improved wearing comfort, and increased gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

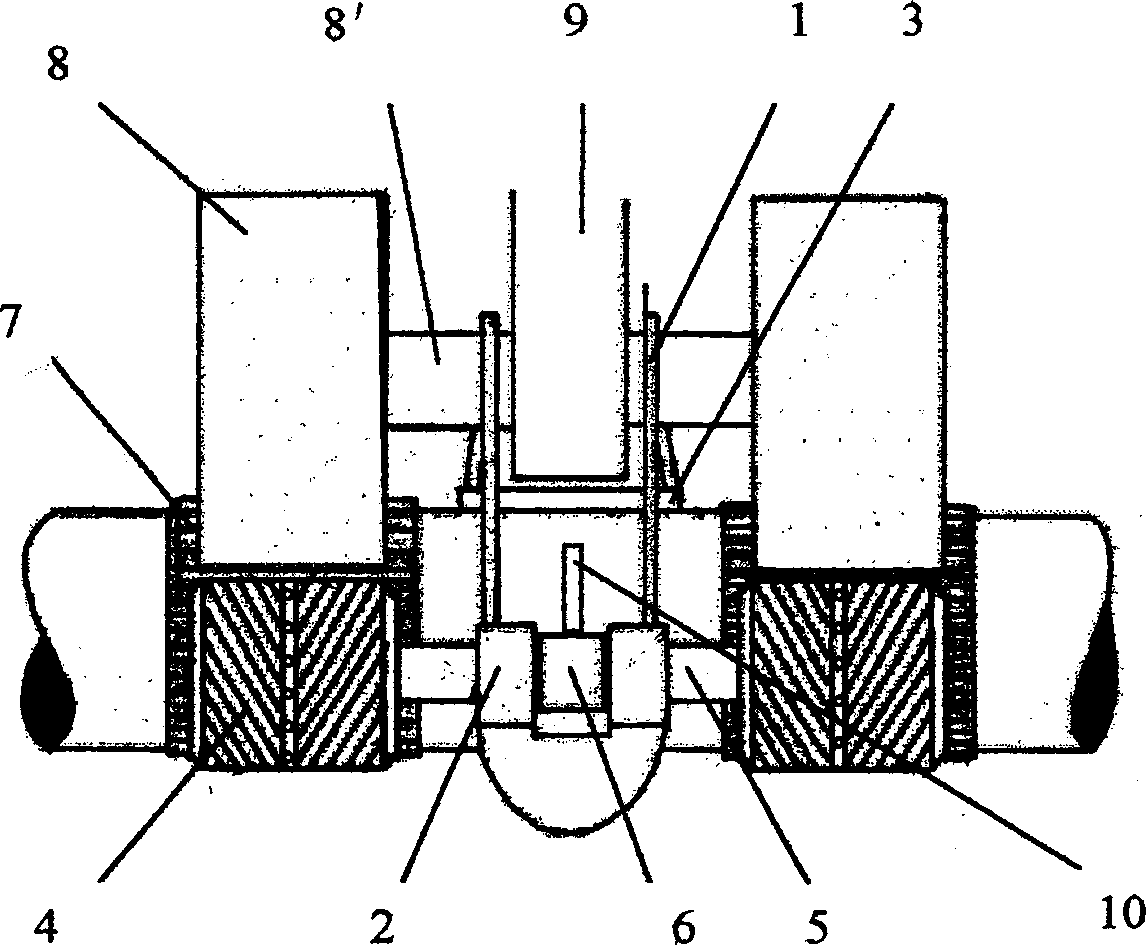

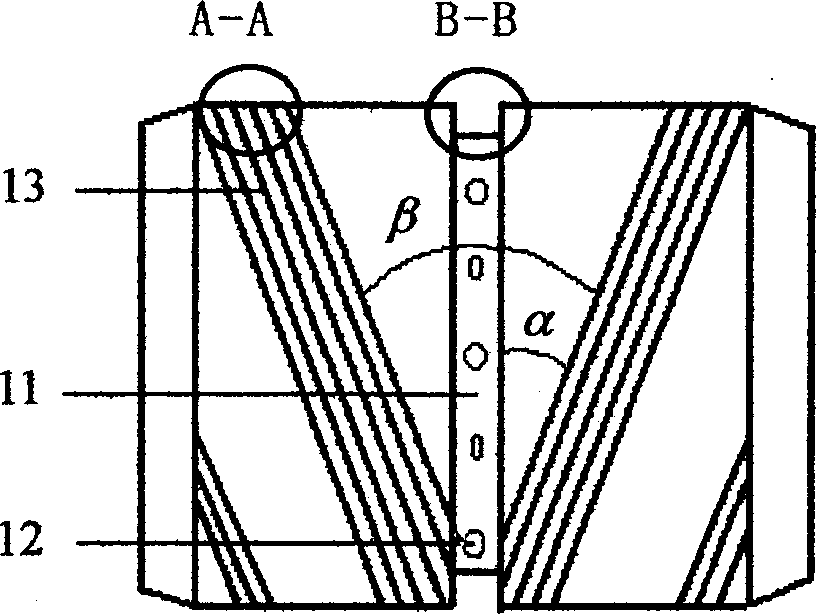

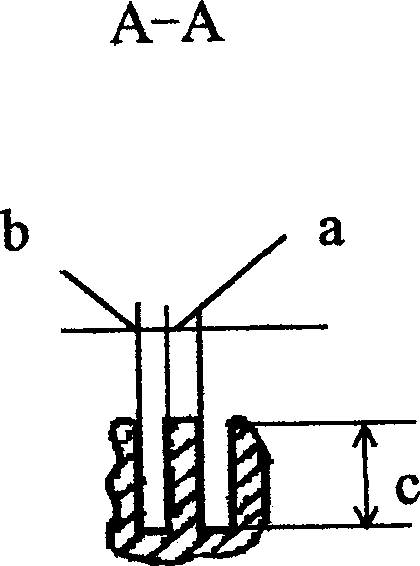

[0027] The invention provides a gathering device for polyfiber strands in an air trough, which is suitable for spinning frames. The polyfiber strand accumulating device in the air slot is installed between the outlet of the front nip in the drafting area of the spinning frame and the spinning section, and the poly fiber strand accumulating device in the air slot and the front roller form a fiber nip, On the polyfiber whisker gathering device, several gathering airflows are added through the air holes 12 at the bottom of the gathering groove 11 to provide a flow field for the fibers in the split guiding groove 13 and the gathering groove 11. Through the splitting guide groove 13 of the airflow groove gathering fiber strand gathering device, the fiber strands are split and guided and the airflow in the gathering groove 11 is guided, and the fiber strands are gathered by the airflow in the gathering groove 11, so that the fibers The strands are tightly twisted in the gathering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com