A sizing method for high-strength and high-modulus silicon carbide fibers

A high-modulus silicon carbide and silicon carbide fiber technology, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of unsuitable sizing agent, easy hair, breakage, etc., to avoid frequent brittle fracture, soft friction conditions, The effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A sizing method for high-strength and high-modulus silicon carbide fibers, the workshop temperature is 25°C, the workshop humidity is 60% to 70%, and the vehicle speed is 30m / min; the temperature of the size tank 7 is set to 25°C.

[0046] (1) Sizing agent deployment

[0047] The deionized water, the epoxy resin slurry and the hydrophilic softener are mixed and stirred evenly in a mass ratio of 28:6:3 to obtain a sizing agent, and the solid content of the sizing agent is 8%, and is ready for use;

[0048] The epoxy resin paste is MU series paste with a solid content of 50%; the hydrophilic softener is silicone or glycerin;

[0049] (2) Pre-drying

[0050] Turn on the hot air dryer, raise the temperature to 120°C, and maintain a constant temperature;

[0051] (3) Sizing

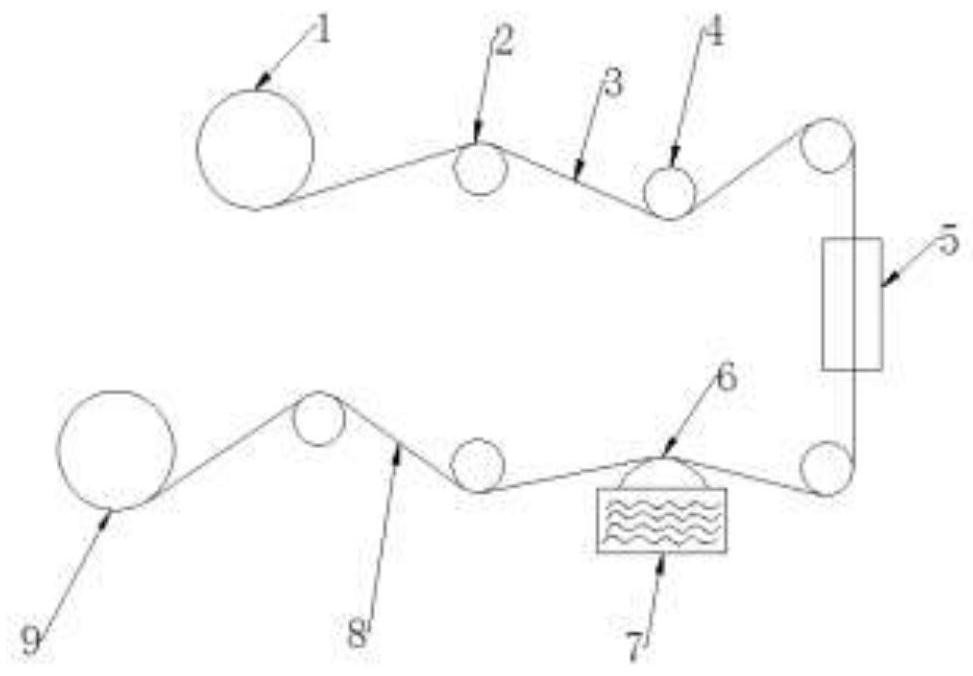

[0052] The silicon carbide fiber 8 is wound on the bobbin 9, enters the sizing tank 7 through the sizing roller 6, and pours the sizing agent into the sizing tank 7 to perform sizing treatment on a s...

Embodiment 2

[0058] A sizing method for high-strength and high-modulus silicon carbide fibers, the workshop temperature is 25°C, the workshop humidity is 60% to 70%, and the vehicle speed is 30m / min; the temperature of the size tank 7 is set to 25°C.

[0059] (1) Sizing agent deployment

[0060] The deionized water, the epoxy resin slurry and the hydrophilic softener are mixed and stirred evenly in a mass ratio of 28:6:3 to obtain a sizing agent, and the solid content of the sizing agent is 8%, and is ready for use;

[0061] The epoxy resin paste is MU series paste with a solid content of 50%; the hydrophilic softener is silicone or glycerin;

[0062] (2) Pre-drying

[0063] Turn on the hot air dryer, raise the temperature to 120°C, and maintain a constant temperature;

[0064] (3) Sizing

[0065] The silicon carbide fiber 8 is wound on the bobbin 9, enters the sizing tank 7 through the sizing roller 6, and pours the sizing agent into the sizing tank 7 to perform sizing treatment on a s...

Embodiment 3

[0071] A sizing method for high-strength and high-modulus silicon carbide fibers, the workshop temperature is 25°C, the workshop humidity is 60% to 70%, and the vehicle speed is 30m / min; the temperature of the size tank 7 is set to 25°C.

[0072] (1) Sizing agent deployment

[0073] The deionized water, the epoxy resin slurry and the hydrophilic softener are mixed and stirred evenly in a mass ratio of 28:6:3 to obtain a sizing agent, and the solid content of the sizing agent is 8%, and is ready for use;

[0074] The epoxy resin paste is MU series paste with a solid content of 50%; the hydrophilic softener is silicone or glycerin;

[0075] (2) Pre-drying

[0076] Turn on the hot air dryer, raise the temperature to 120°C, and maintain a constant temperature;

[0077] (3) Sizing

[0078] The silicon carbide fiber 8 is wound on the bobbin 9, enters the sizing tank 7 through the sizing roller 6, and pours the sizing agent into the sizing tank 7 to perform sizing treatment on a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com