Dual-circulation absorption tower

An absorption tower and double-circuit technology, which is applied in the field of absorption tower equipment for efficiently removing pollutants in coal-fired flue gas, can solve the problems of increasing circulating pumps, increasing operating costs, and high use costs, and achieves optimal operating environment and good desulfurization effect , the effect of high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

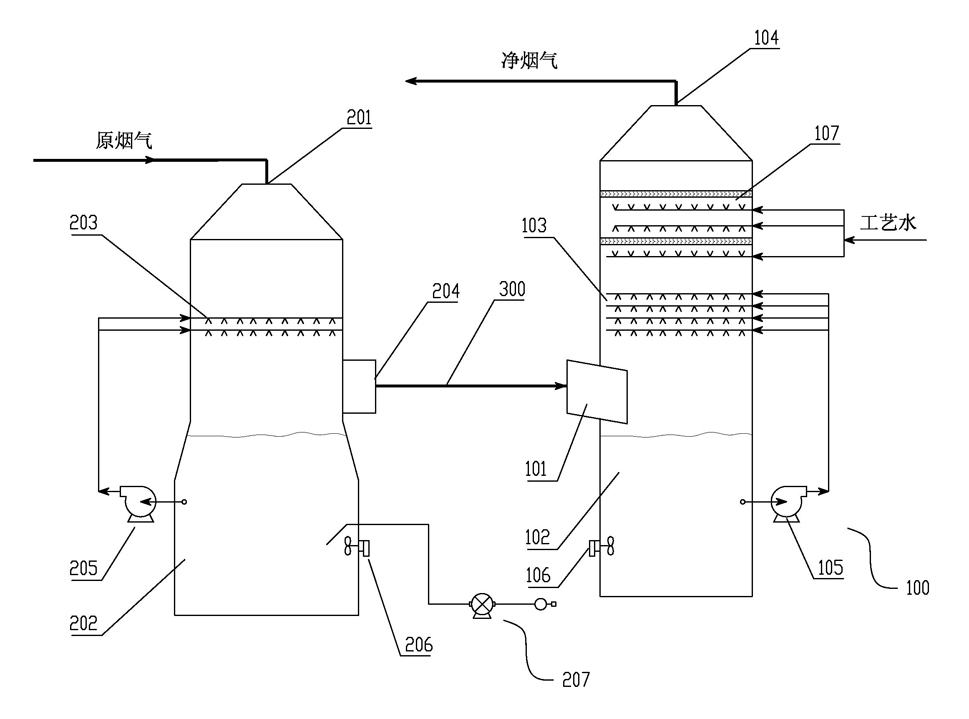

[0022] See attached picture. The dual-loop absorption tower in this embodiment includes: a pre-absorption tower 200 and a main absorption tower 100, and the two absorption towers are arranged in series on the flue gas passage. The main absorption tower 100 of this embodiment is a counter-flow type, that is, the flue gas direction P passes through the spray area from bottom to top, and the pre-absorption tower 200 adopts a downstream type, that is, the flue gas direction P passes from top to bottom spray area.

[0023] The pre-absorption tower 200 includes a second flue gas inlet 201, a second slurry tank 202, a second spray area 203 containing two spray layers, a second flue gas outlet 204, a second slurry circulation pump 205, and a second slurry Stirrer 206 and forced oxidation device 207, wherein, the second slurry tank 202 is located at the bottom of the pre-absorption tower, the gas-liquid contact zone is located above the second slurry tank 202, and the second spray zon...

Embodiment 2

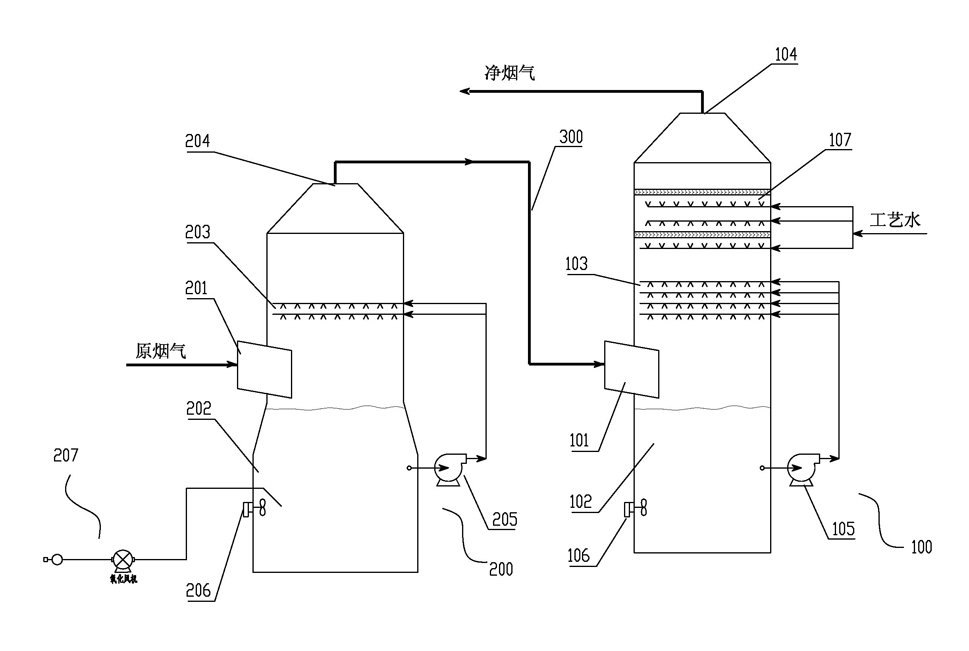

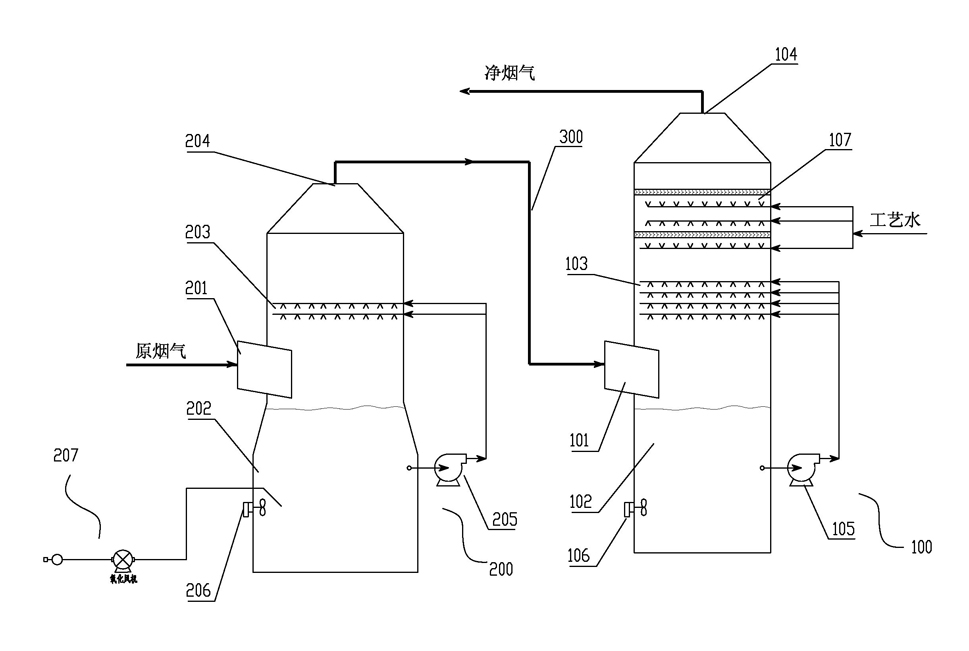

[0026] see figure 2 . The difference between the dual-circuit absorption tower of this embodiment and that of Embodiment 1 is that both the main absorption tower and the pre-absorption tower in Embodiment 1 adopt the operation mode of countercurrent spraying, that is, the flue gas direction P is from bottom to top. Overspray zone 203. Compared with the dual-circuit absorption tower in Embodiment 1, the double-circuit absorption tower of this embodiment can make the gas-liquid contact more fully, and can further improve the desulfurization efficiency under the premise of other conditions being the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com