Complex twisting device for air-jet eddy-current spinning

A twister and vortex spinning technology, which is applied in the field of air-jet vortex spinning compound twisters, can solve the problems affecting the quality of yarn and finished fabric products, save the singeing process and waxing process, and improve wearing comfort , The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

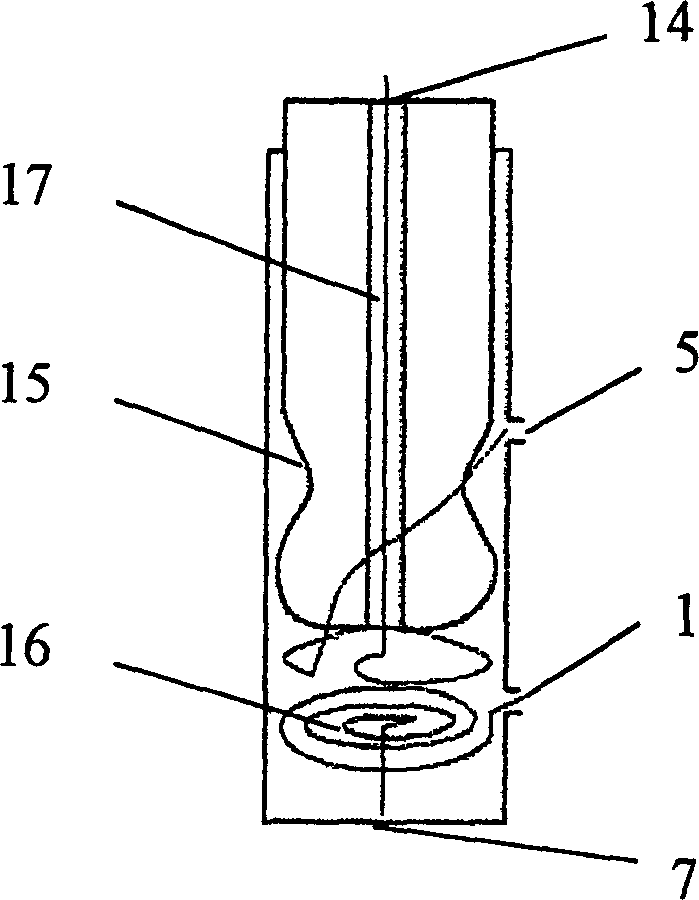

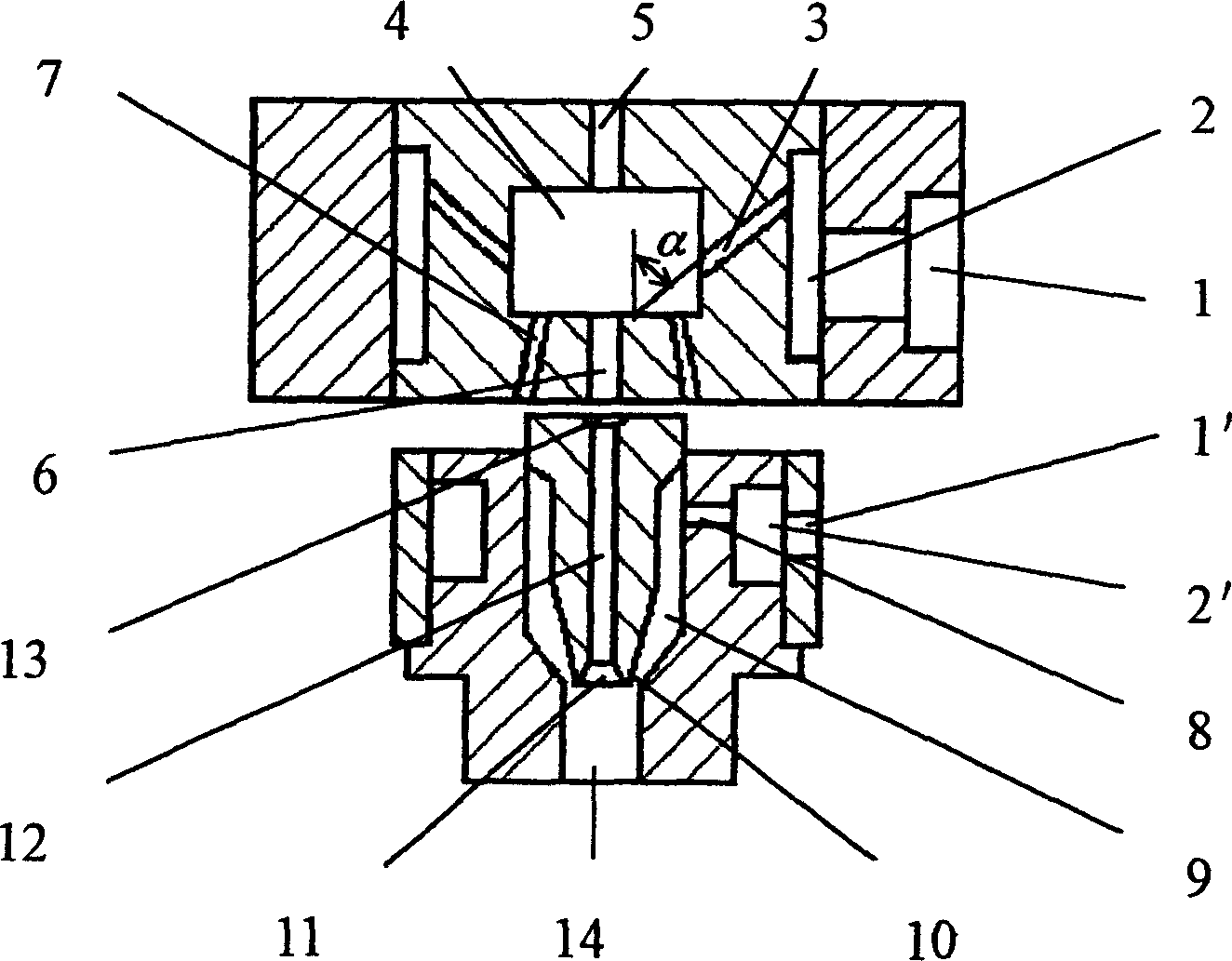

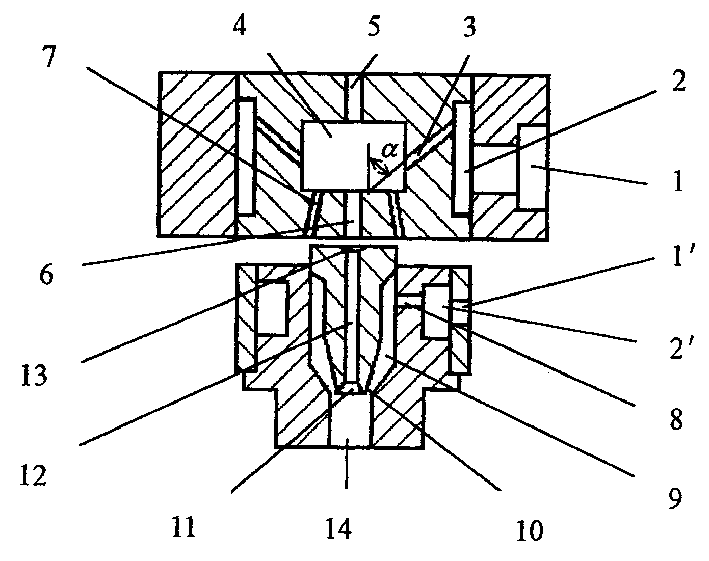

[0016] The present invention installs a newly conceived air-jet vortex spinning compound twister between the drafting area and the winding area of the spinning machine. The air-jet vortex spinning compound twister is composed of an upper twister and a lower twister. It uses a positive pressure airflow to generate a vortex field and a pipe flow. The fibers enter the vortex field through the conveying pipe, and the fiber strands rotate with the high-speed rotating airflow. While the fiber strands are rotating at high speed, the pipe flow protects and guides the twisting fiber strands to leave the eddy current field quickly, during which the fiber strands complete the twisting and produce twisted yarn at high speed. Such as figure 2 As shown, the upper twister generates a positive pressure vortex field through the positive pressure airflow generated by the compressor, and the negative pressure in the center of the vortex field sucks the fiber flow and drives the fiber strands ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com