Ground pregrouting material prepared from waste drilling slurry

A waste mud and pre-grouting technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of large floor area, environmental pollution, and unsatisfactory curing effect, so as to reduce the amount of mud production and ease Great pressure, the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

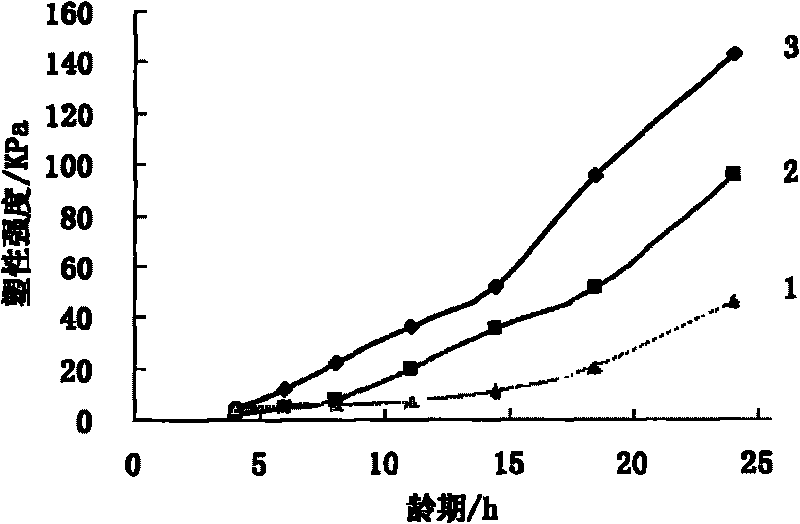

[0013] Example 1: Drilling mud is taken from the westerly well of Zhangbei Coal Mine in Huainan, with a dilution specific gravity of 1.16 and a funnel viscosity of 18.91s. Under the test condition of 25°C, add drilling waste mud into the mixing pot of the cement mortar mixer, select a low speed and turn on the stirring pot, add calcium chloride solution, stir for 1 minute, add cement and stir for 3 minutes, then add structural additives, low speed After stirring for 1 min, the viscosity of the prepared slurry was measured with a funnel viscometer. During the slurry preparation process, the mixer has been in a low-speed stirring state. Considering the dilution effect of the calcium chloride solution, the same amount of water was used as a comparative test. According to the performance of the grouting material in "Coal Mine Grouting Technology" and the commonly used test methods, the funnel viscosity of the grout is measured. The test ratio and measurement results are shown in...

Embodiment 2

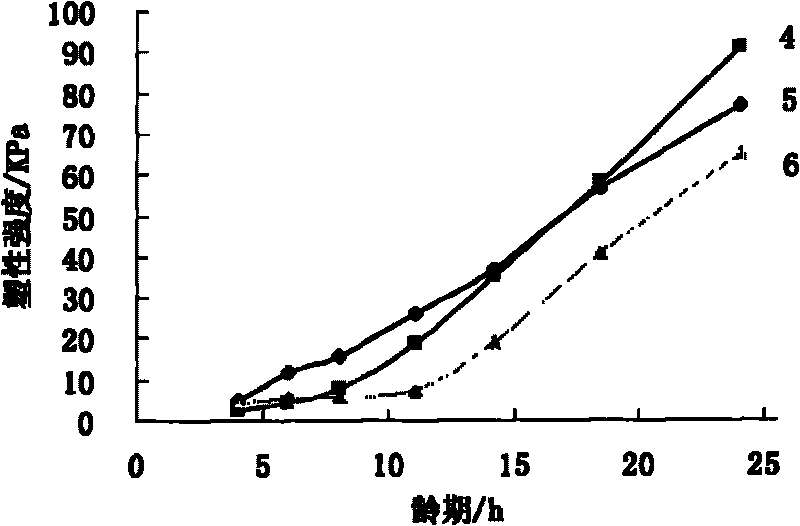

[0025] Embodiment 2: According to the experimental method of embodiment 1, the experiment was carried out with the drilling mud of the main shaft of the No. 2 Yuandian Coal Mine in Huaibei. The specific gravity dilution of the drilling mud is 1.21, and the measured funnel viscosity is 19.44s. Viscosity measurement is shown in Table 2, 24h plastic strength growth trend of slurry figure 2 shown.

[0026] Calcium Chloride Reduced Viscosity Determination Table Table 2

[0027]

[0028] The slurry prepared with the drilling mud of the main well of Yuandian No. 2 Mine in Huaibei, after adding calcium chloride, the plastic strength of the slurry can reach 50KPa in 18h-22h, which can meet the water shutoff requirements. Through the viscosity-reducing effect of calcium chloride, the grouting material prepared with the waste drilling mud meets the ground pre-grouting requirements.

Embodiment 3

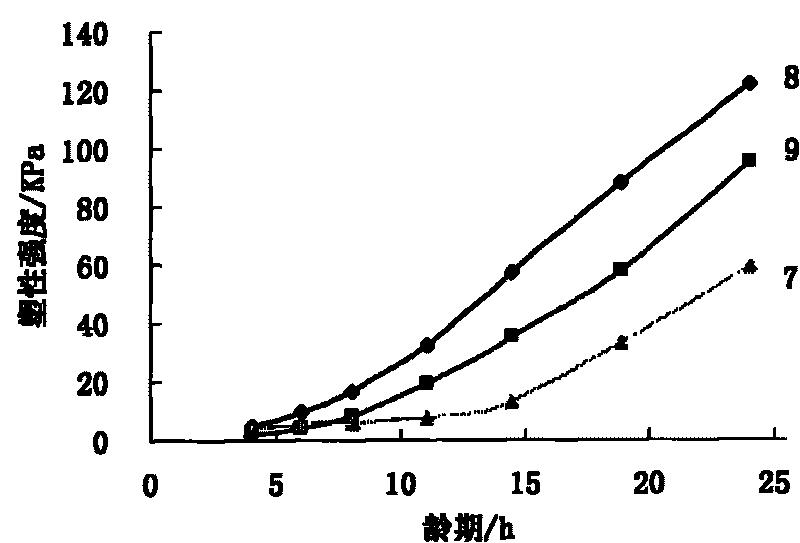

[0029] Example 3: still according to the experimental method of Example 1, the experiment was carried out with the drilling mud from the gangue well of Zhujixi Mine in northern Anhui. The specific gravity dilution of the drilling mud is 1.13, and the measured funnel viscosity is 22.13s. Viscosity measurement is shown in Table 3, the plastic strength growth trend of the slurry at 24 hours image 3 shown.

[0030] Calcium Chloride Reduced Viscosity Determination Table Table 3

[0031]

[0032] After adding calcium chloride to the slurry prepared from the drilling mud of gangue wells in Zhujixi Mine in northern Anhui, the plastic strength of the slurry can reach 50KPa at 14h, 18h and 22h respectively, which can meet the water shutoff requirements. Through the viscosity-reducing effect of calcium chloride, the grouting material prepared with the waste drilling mud meets the ground pre-grouting requirements.

[0033] In the above embodiment, the cement mortar mixer is JJ-5 ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com