Technological method for drilling fluid solid control circulation system

A process method and technology of circulation system, which are applied in the field of drilling fluid solid control circulation system technology, can solve the problems of affecting the treatment effect, high cost of accessories, no concentration process, etc., and achieve the effect of good concentration effect, reducing volume and increasing concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

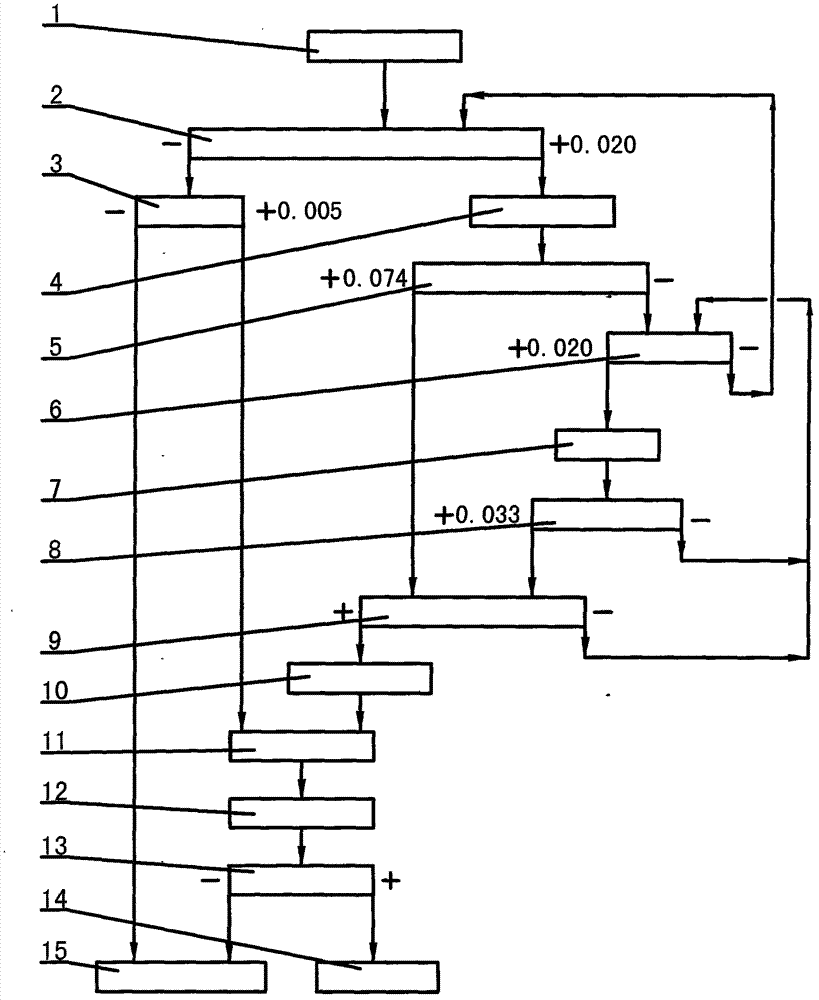

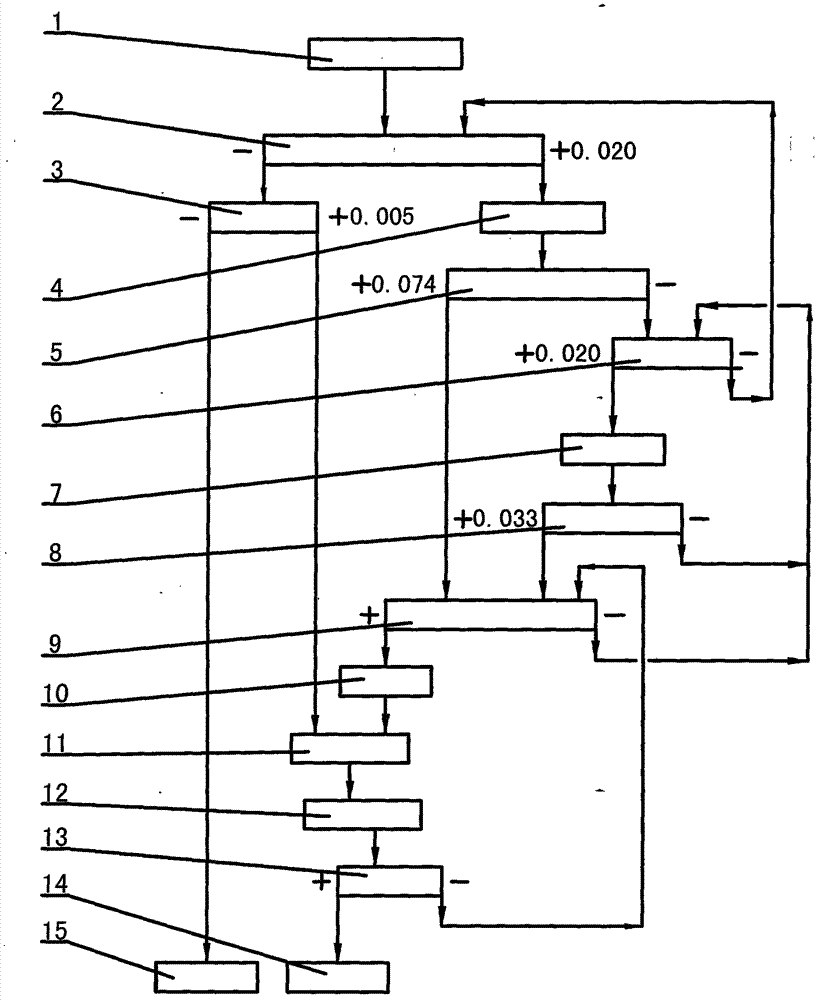

[0030] ① Drilling fluid (1) is concentrated and treated by the special concentration processor I (2), and classified into two parts: -0.020mm drilling fluid and +0.020mm drilling fluid: -0.020mm drilling fluid directly enters the special centrifuge (3 ) is classified into -0.005mm drilling fluid and +0.005mm drilling fluid after treatment, -0.005mm drilling fluid flows into the circulating fluid storage tank (15), and +0.005mm drilling fluid flows into the storage tank (11); The +0.020mm drilling fluid is transported to the special cyclone group I(5) through the oilfield mud pump I(4) and classified into two parts: -0.074mm drilling fluid and +0.074mm drilling fluid; ②Through the special cyclone group I (5) After classification, the +0.074mm drilling fluid flows directly into the special concentration processor III (9); the -0.074mm drilling fluid flows into the special concentration processor II (6), and the concentration is +0.020 after the concentration treatment mm drillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com