Organo-mineral biochar complex formula fertilizer and preparation method thereof

A technology of organic fertilizer and biochar, applied in the direction of organic fertilizer, excretion fertilizer, fertilizer mixture, etc., can solve the problems of environmental nitrogen leaching, salt accumulation hazards, short-term decomposing, etc., to improve the utilization rate of nutrient elements, improve Cation exchange capacity, the effect of reducing the activity of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

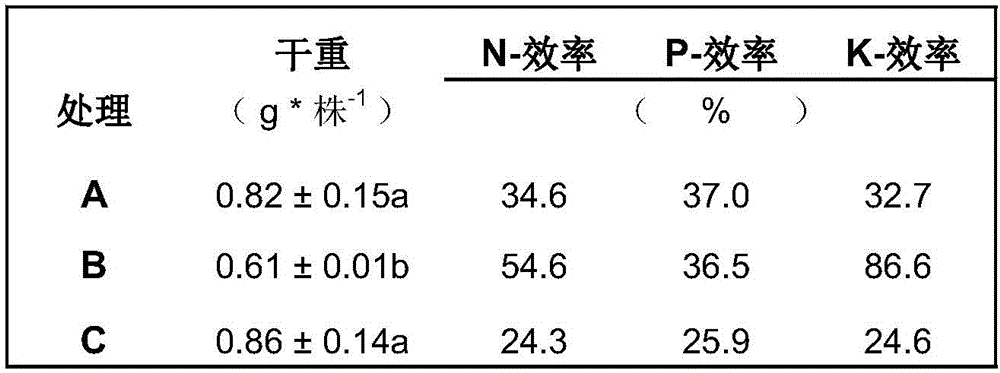

Image

Examples

Embodiment 1

[0053] Embodiment 1, prepare one section of organic-inorganic biochar composite formula fertilizer

[0054] (1) Break up large pieces of manure such as animal-source organic matter such as cow manure, chicken manure, and pig manure, pass through a 5cm large-hole sieve, and then mix with biochar to obtain a premix; wherein the quality of biochar is premix 20% of the total mass of the material.

[0055] (2) carry out composting fermentation to the premix in step (1);

[0056] Before composting and fermentation, the following steps are also included:

[0057] 2-1) Add water to the premixed material obtained in step 1), and control the water content of the mixture to 25%.

[0058] 2-2) Add an organic matter degrading enzyme (plant proteolytic enzyme) to the premix treated in the above 2-1) in an amount of 1% of the mass of the premix (ie 3 million IU / kg premix) .

[0059] 2-3) Add a biodegradation agent to the mixture obtained in the above 2-2): earthworms and fermenting micro...

Embodiment 2

[0065] Embodiment 2, preparation of two-stage organic-inorganic biochar composite formula fertilizer

[0066] (1) Break up large pieces of manure such as animal-source organic matter such as cow manure, chicken manure, and pig manure, pass through a 5cm large-hole sieve, and then mix with biochar to obtain a premix; wherein the quality of biochar is premix 20% of the total mass of the material.

[0067] (2) carry out composting fermentation to the premix in step (1);

[0068] Before composting and fermentation, the following steps are also included:

[0069] 2-1) Add water to the premixed material obtained in step 1), and control the water content of the mixture to 25%.

[0070] 2-2) Add an organic matter degrading enzyme (plant proteolytic enzyme) to the premix treated in the above 2-1) in an amount of 1% of the mass of the premix (ie 3 million IU / kg premix) .

[0071]2-3) Add a biodegradation agent to the mixture obtained in the above 2-2): earthworms and fermenting micr...

Embodiment 3

[0077] Example 3, preparation of three-stage organic-inorganic biochar compound formula fertilizer

[0078] (1) Break up large pieces of manure such as animal-source organic matter such as cow manure, chicken manure, and pig manure, pass through a 5cm large-hole sieve, and then mix with biochar to obtain a premix; wherein the quality of biochar is premix 30% of the total mass of the material.

[0079] (2) carry out composting fermentation to the premix in step (1);

[0080] Before composting and fermentation, the following steps are also included:

[0081] 2-1) Add water to the premixed material obtained in step 1), and control the water content of the mixture to 25%.

[0082] 2-2) Add an organic matter degrading enzyme (plant proteolytic enzyme) to the premix treated in the above 2-1) in an amount of 1% of the mass of the premix (ie 3 million IU / kg premix) .

[0083] 2-3) Add a biodegradation agent to the mixture obtained in the above 2-2): earthworms and fermenting micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com