Organic wastewater deep degradation reaction device and application

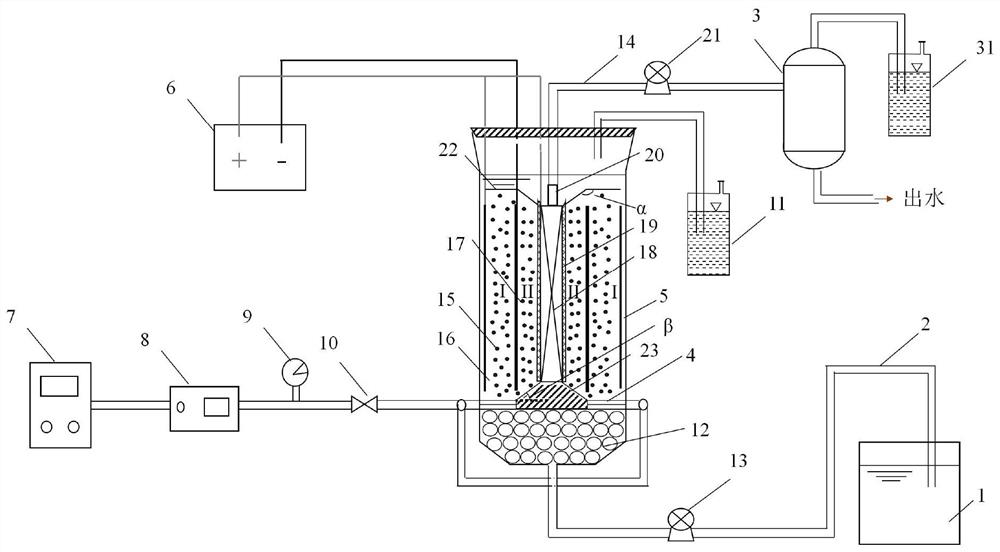

A technology of organic wastewater and degradation reaction, applied in the direction of water aeration, water pollutants, electrolytic coatings, etc., can solve the problems of low generation rate, organic wastewater treatment rate and efficiency to be further improved, and achieve small footprint, effective Facilitate degradation and improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

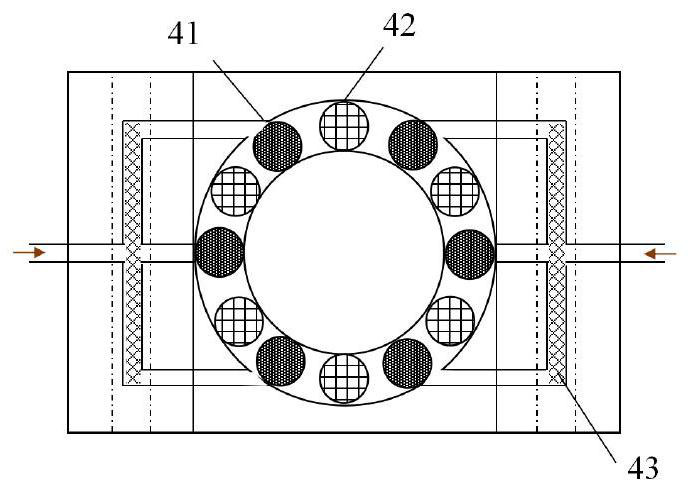

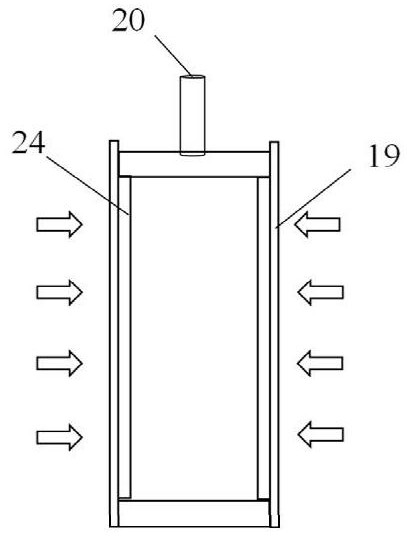

[0064] 1.1 The preparation method of the cylindrical gas diffusion electrode is as follows:

[0065](1) Stainless steel substrate pretreatment: the cylindrical stainless steel substrate (tube diameter is 6.5cm, height is 25cm) is placed in the NaOH solution of 40% mass fraction and soaks 30min, rinses with deionized water; %H 2 SO 4 Soak in the solution at 60°C for 20 minutes, take it out and wash it; finally etch it in 20% oxalic acid solution at 90°C for 2 hours;

[0066] (2) Preparation of electrode material paste: Weigh an appropriate amount of Fe 3 o 4 Dope activated carbon and acetylene black into a beaker, add a small amount of absolute ethanol and ultrasonically stir to disperse evenly, then add an appropriate amount of PTFE emulsion with a mass fraction of 60%, and continuously stir the cohesive paste in a constant temperature water bath at 80°C. The paste is rolled into two thin slices with a thickness of 0.5mm with a laminating machine for use; wherein, Fe 3 o ...

Embodiment 2

[0074] Embodiment 2: the treatment of typical antibiotic levofloxacin simulated wastewater

[0075] The typical antibiotic levofloxacin simulated wastewater is treated with the organic wastewater advanced degradation reaction device based on the internal circulating fluidized bed of Example 1. The experimental parameters are: the reaction volume is 2.4L; the initial concentration of levofloxacin in the influent is 200mg / L; the initial pH of the solution is 7.0 ; Inlet gas phase O 3 The concentration is about 15mg / L; the gas flow rate is 0.5L / min; the current density is 10mA / cm 2 ; Electrolyte Na 2 SO 4 The concentration is 0.05mol / L. The reactor is set to operate in the continuous flow mode of operation, and the electrochemical membrane module is operated at a flux of 75L / (m 2 ·h) Operation, the hydraulic retention time is 1h. Within 1 hour of reaction time, the parent pollutant levofloxacin was completely removed, and the removal rate of TOC was 68.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com