Double tail-removing gravity-flotation combined sorting method and device

A classification device, tail weight technology, applied in flotation, solid separation and other directions, can solve the problems of low fine particle separation effect of flotation machine, difficult to effectively connect the upper limit of flotation column flotation, etc., to achieve improved flotation effect, Improve the upper limit of sorting and reduce the loss of low ash and coarse particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

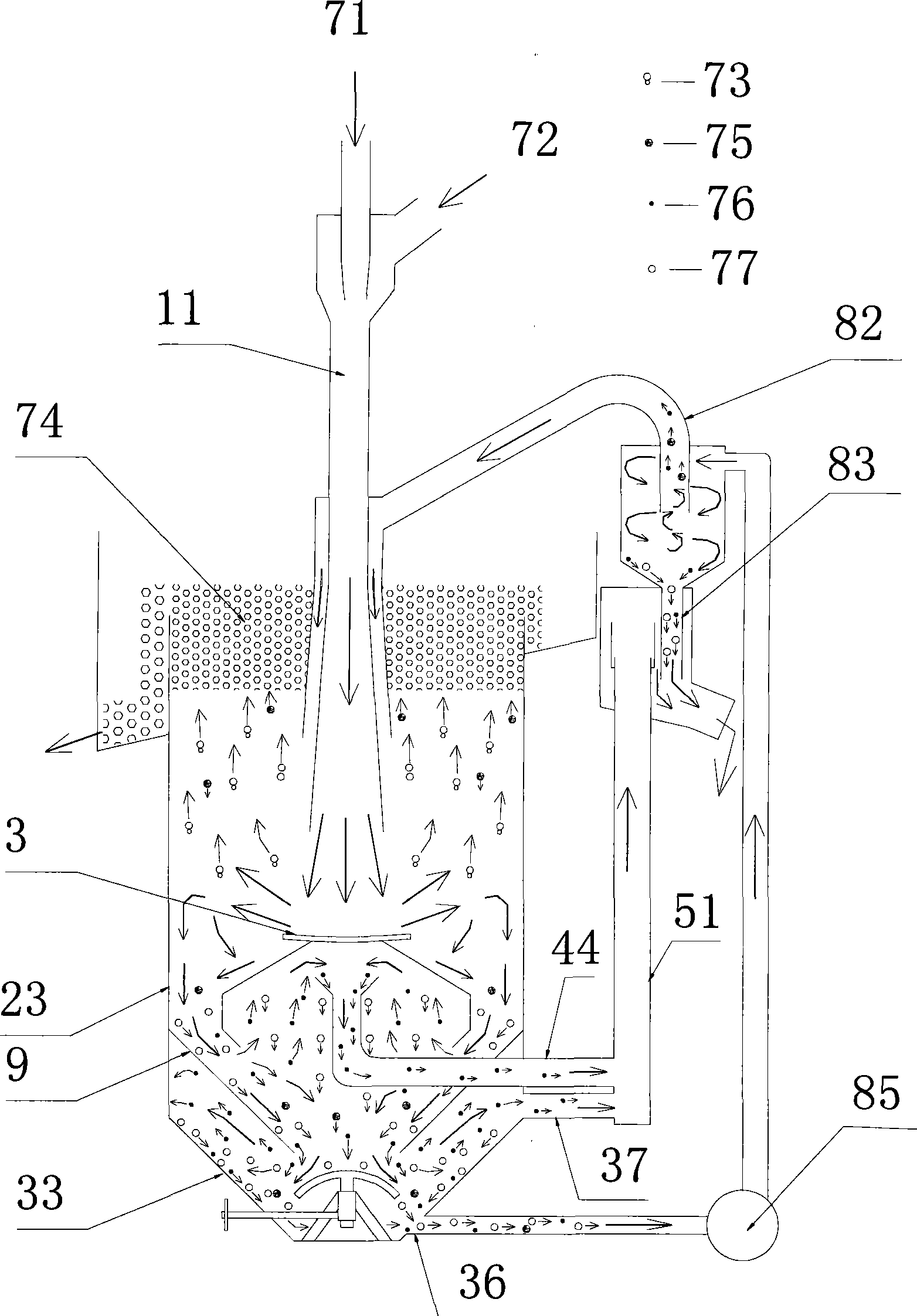

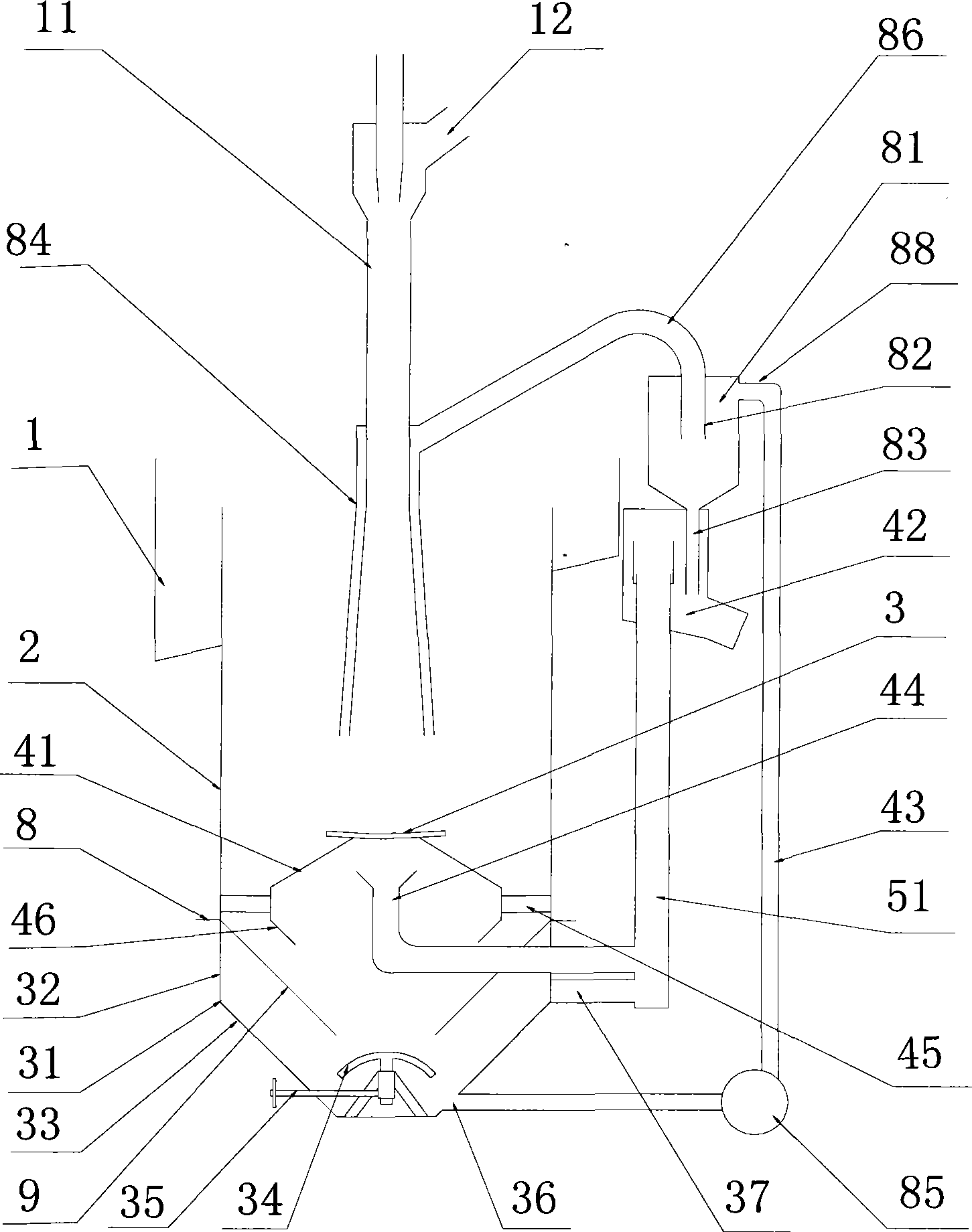

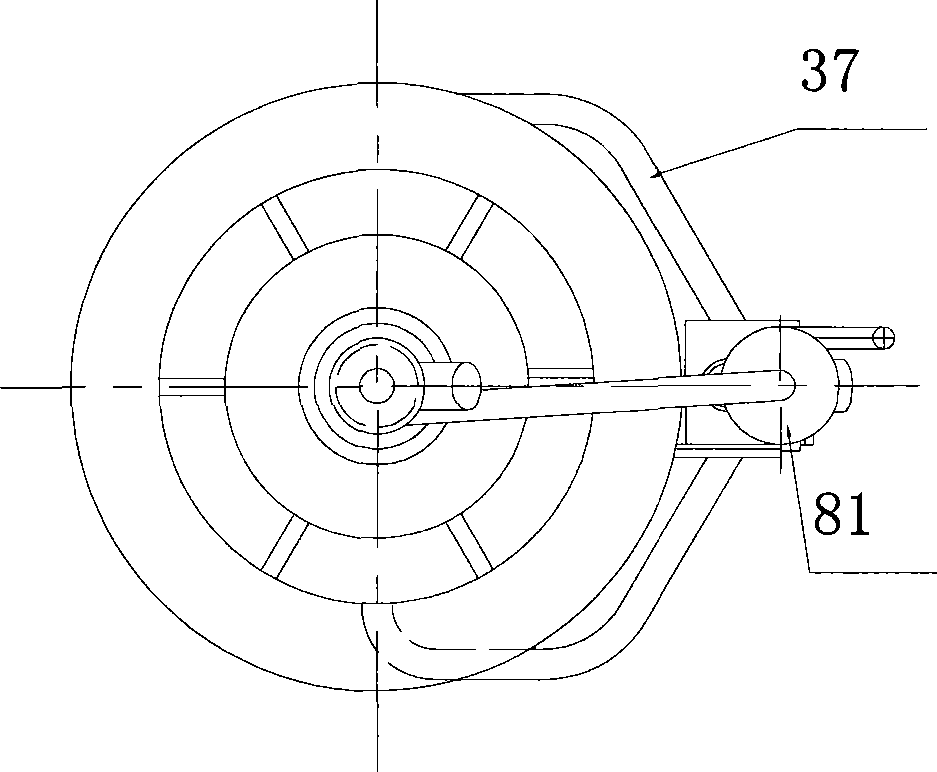

[0029] Such as figure 1 As shown, the combined separation method with double tails and heavy flotation in this embodiment includes three steps of raw ore flotation roughing and grading tailing, gravity sweeping tailing and gravity separation concentrate and flotation again:

[0030](1) Raw ore flotation roughing and grading and tailing: the raw material pulp 71 is pumped from the feed to the jet device 11 above the flotation column, and during the process of the pulp passing through the jet device at high speed, the air 72 is drawn by the air suction port of the jet device Inhaled and fully mixed with the pulp, the flotation agent is also added from the air suction port, inflated and mineralized in the ejector, and then injected into the flotation column 23, colliding with the concave spherical reflector 3, and the bubbles are further crushed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com