Turbulent flow regulating and controlling external particle fluidized bed mineralizing and floating device uniform in turbulence degree

A particle fluidization and turbulence technology, applied in flotation, solid separation, etc., can solve the problems of unadjustable turbulence, low energy utilization rate, low energy dissipation rate, etc., to improve flotation recovery rate, The effect of high mineralization efficiency and high energy dissipation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

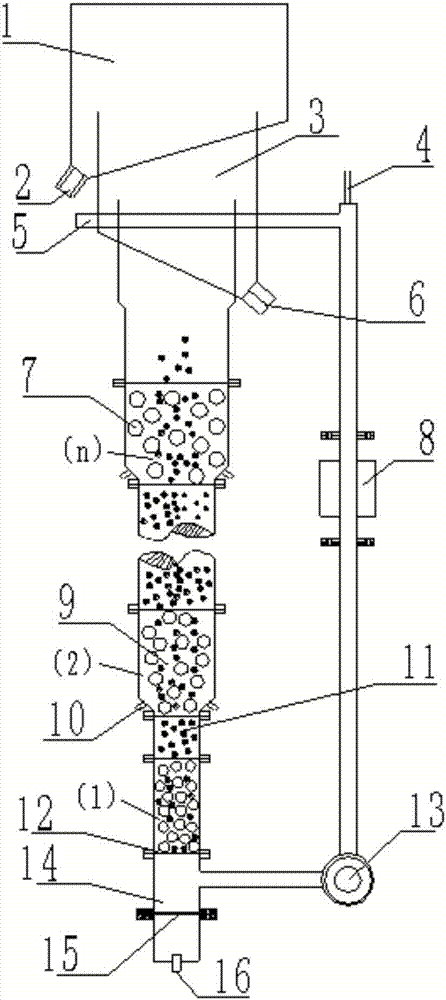

[0022] like figure 1 As shown, the turbulence regulation of the present invention with a uniform turbulence degree plus a particle fluidized bed is mainly composed of a flotation column, a concentrate overflow tank 1, a sieve plate 12, a gas distributor 15 and a circulation pump 13. The column selection includes a column flotation zone 3, a fluidized bed mineralization flotation zone 9 and a gas-liquid mixing zone 14 located at the lower part of the column flotation zone 3, and the upper part of the column flotation zone 3 is provided with a concentrate overflow tank 1. Concentrate overflow tank 1 is provided with concentrate discharge port 2, tailings discharge port 6 is provided at the bottom of column flotation area 3, and medium ore circulation port 5 is provided outside, and the medium ore circulation port 5 is connected to the feed port 4 are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com