Waste gas emission wind power generation device

A wind power generation device and exhaust gas emission technology, which is applied in wind power generation, wind turbines, wind turbine combinations, etc., can solve the problems of high exhaust gas emission rate, unsuitable for large-scale application, large infrastructure investment, etc., to achieve convenient maintenance, Strong practicality and promotion significance, flexible use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

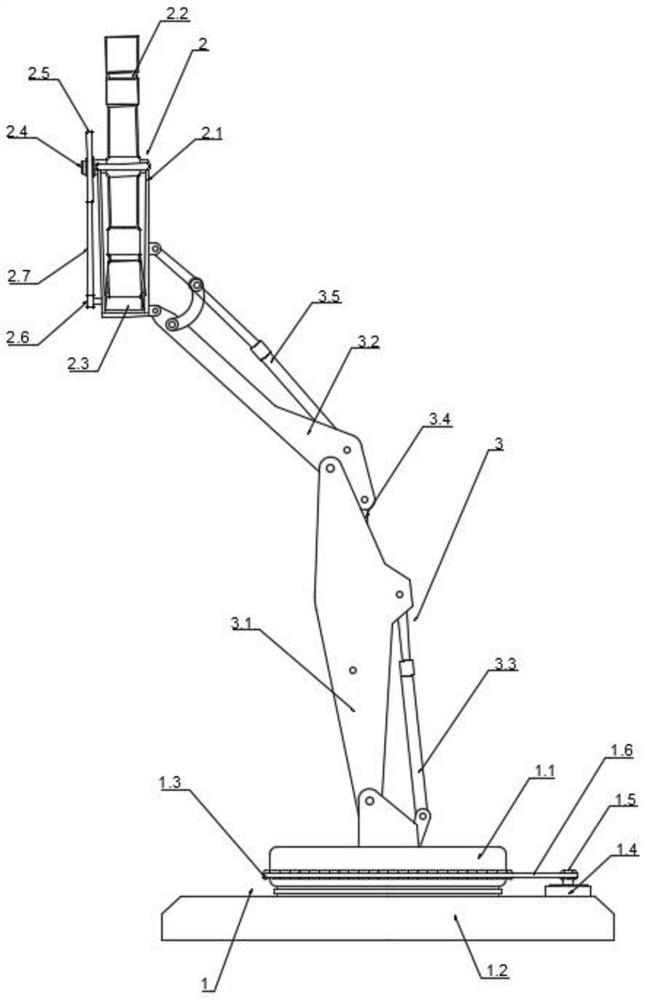

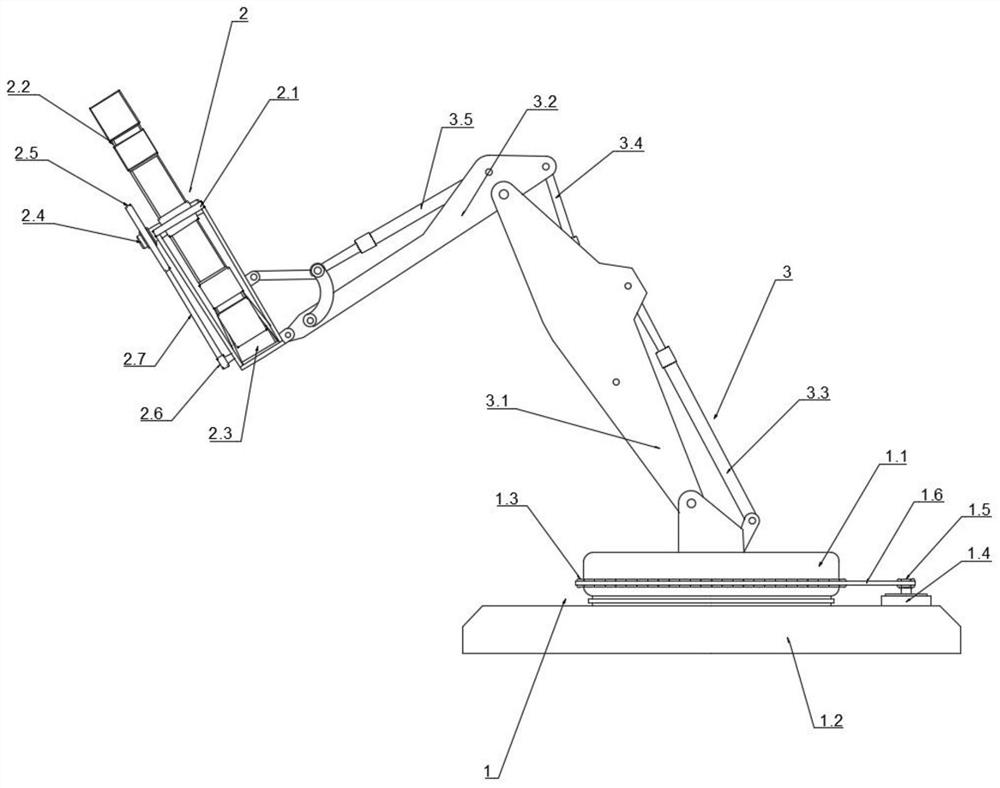

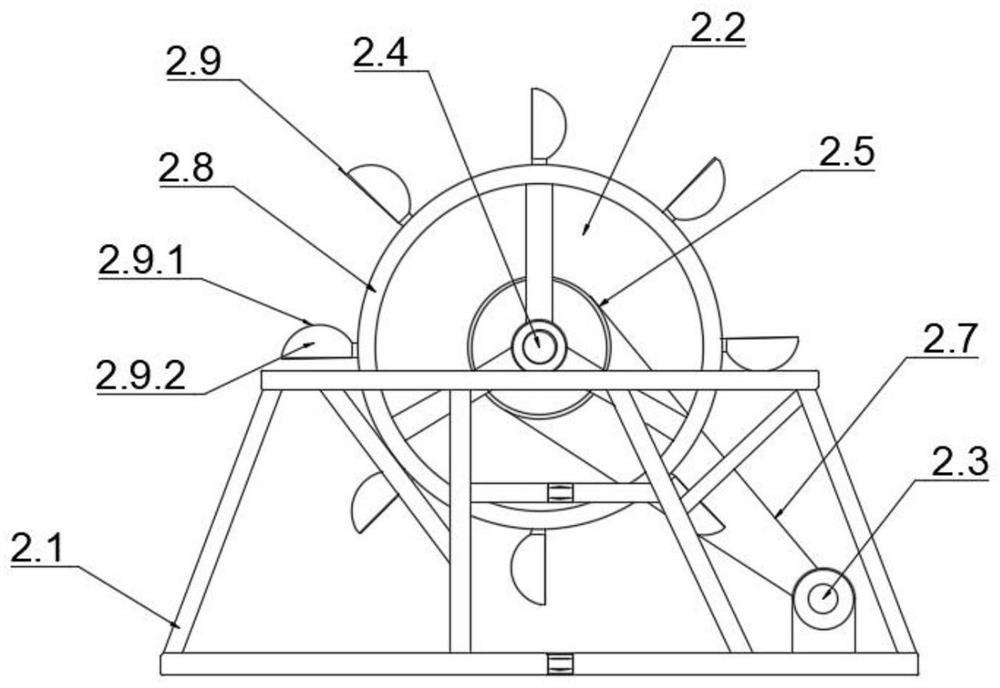

[0024] Such as Figure 1-3 As shown, an exhaust emission wind power generation device includes a base 1, a wind power generation mechanism 2 and a support mechanism 3 connecting the base 1 and the wind power generation mechanism 2, the wind power generation mechanism 2 includes a frame 2.1, and the frame 2.1 is provided with The wind wheel 2.2 and the generator 2.3 connected to the wind wheel 2.2 are rotatably mounted on the frame 2.1; the support mechanism 3 includes a main arm 3.1, a support arm 3.2 hingedly connected with the main arm 3.1, and a main arm 3.1 Hinged on the base 1, the first hydraulic cylinder 3.3 is connected between the main arm 3.1 and the base 1, the cylinder body of the first hydraulic cylinder 3.3 is hinged on the base 1, and the telescopic rod of the first hydraulic cylinder 3.3 is hinged on the support On the arm 3.2; the second hydraulic cylinder 3.4 is connected between the main arm 3.1 and the support arm 3.2, the cylinder body of the second hydrau...

Embodiment 2

[0029] Such as Figure 4 Shown, with reference to embodiment 1, all the other features remain unchanged.

[0030] The base 1 is arranged in the container body 4, and the container body 4 is provided with an opening for the movement of the wind power generating mechanism 2 and the supporting mechanism 3. By arranging the container body 4, the storage and movement of the entire power generating device can be facilitated, and it can be hoisted away by a crane or The trailer is removed to realize the transfer.

Embodiment 3

[0032] Such as Figure 5 Shown, with reference to embodiment 1 and 2, all the other features remain unchanged.

[0033] Container body 4 is arranged on the car body 5, and the both sides of car body 5 is provided with hydraulic brace 6, and hydraulic brace 6 is provided with four groups, and each side of car body 5 is respectively provided with two groups, by setting car body 5 more It is convenient for the flexible transfer of the whole power generation device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com