Pre-distributed material concentrated forming cross wedge rolling technique

A technology of forming wedge and cross wedge rolling, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of poor dimensional stability of products, limited processing capacity of equipment, high requirements of rolling equipment, and reduce the difficulty of equipment adjustment. , The effect of improving the utilization rate of materials and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the examples.

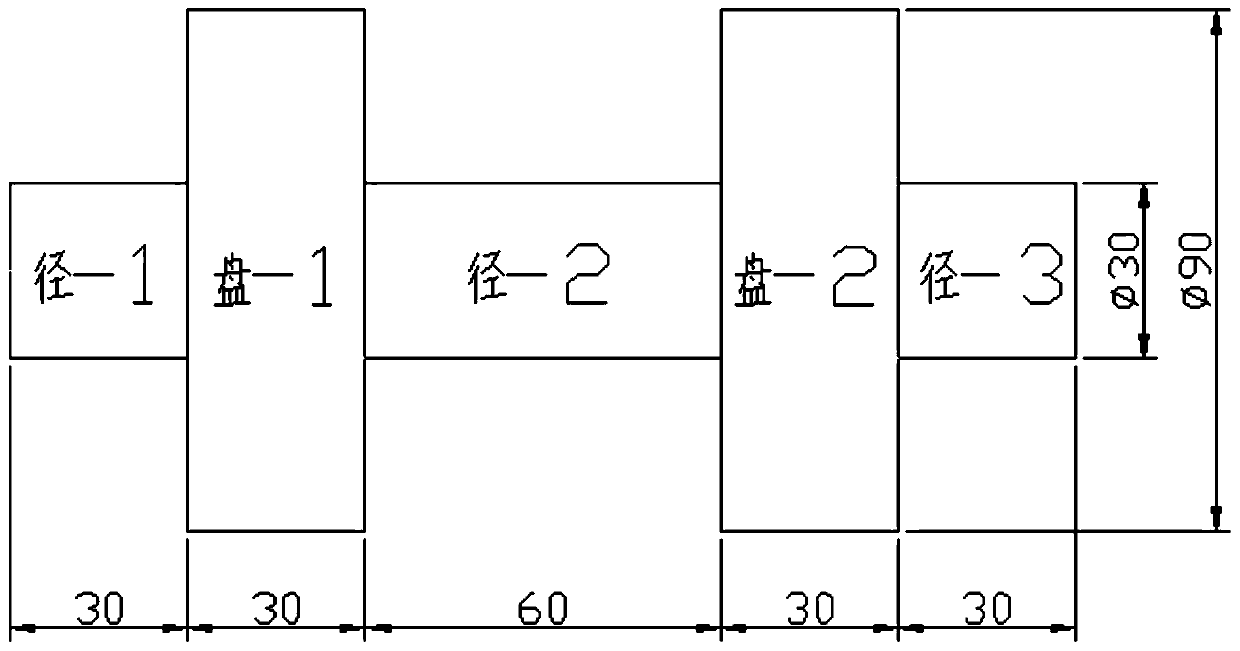

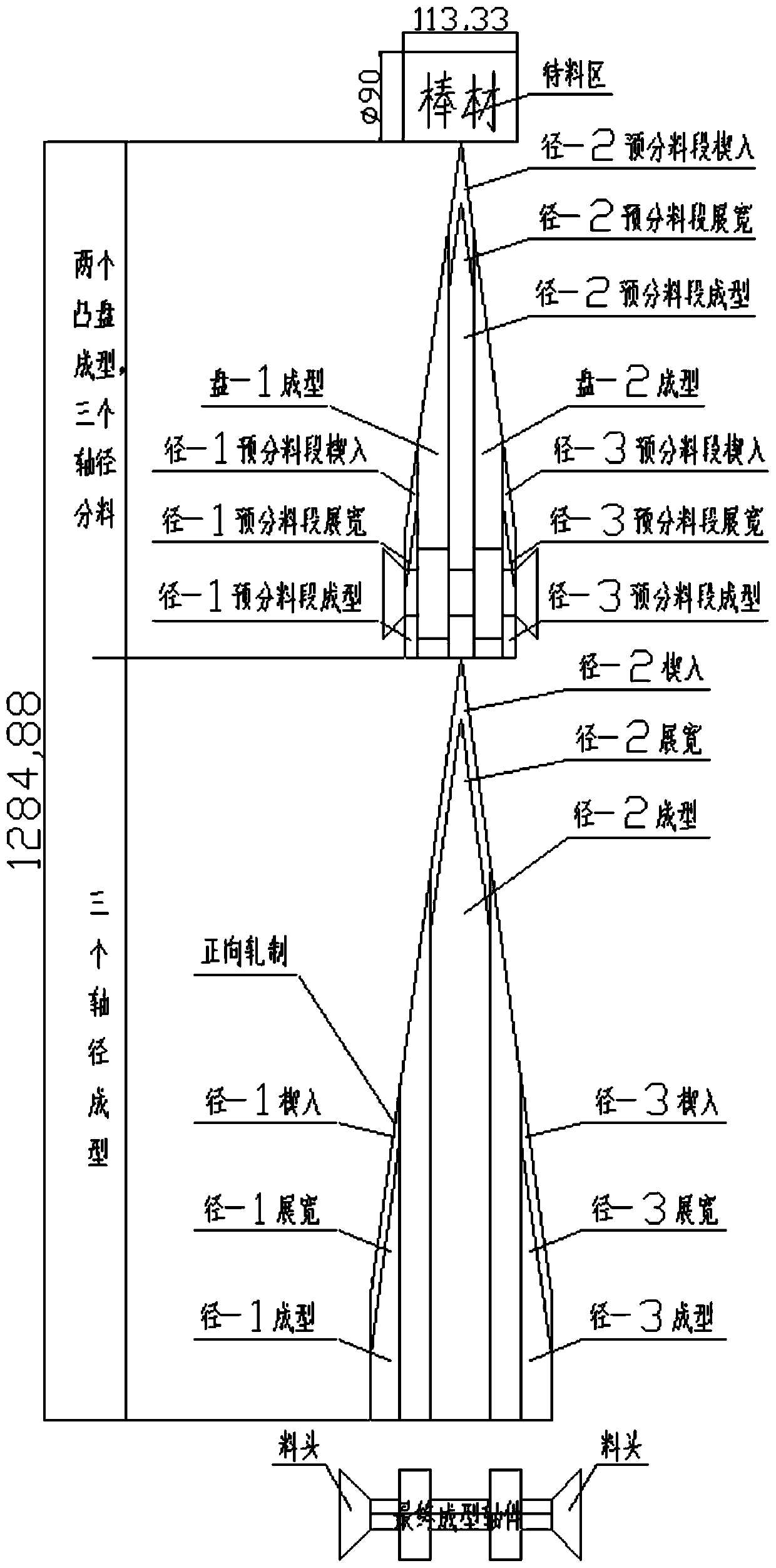

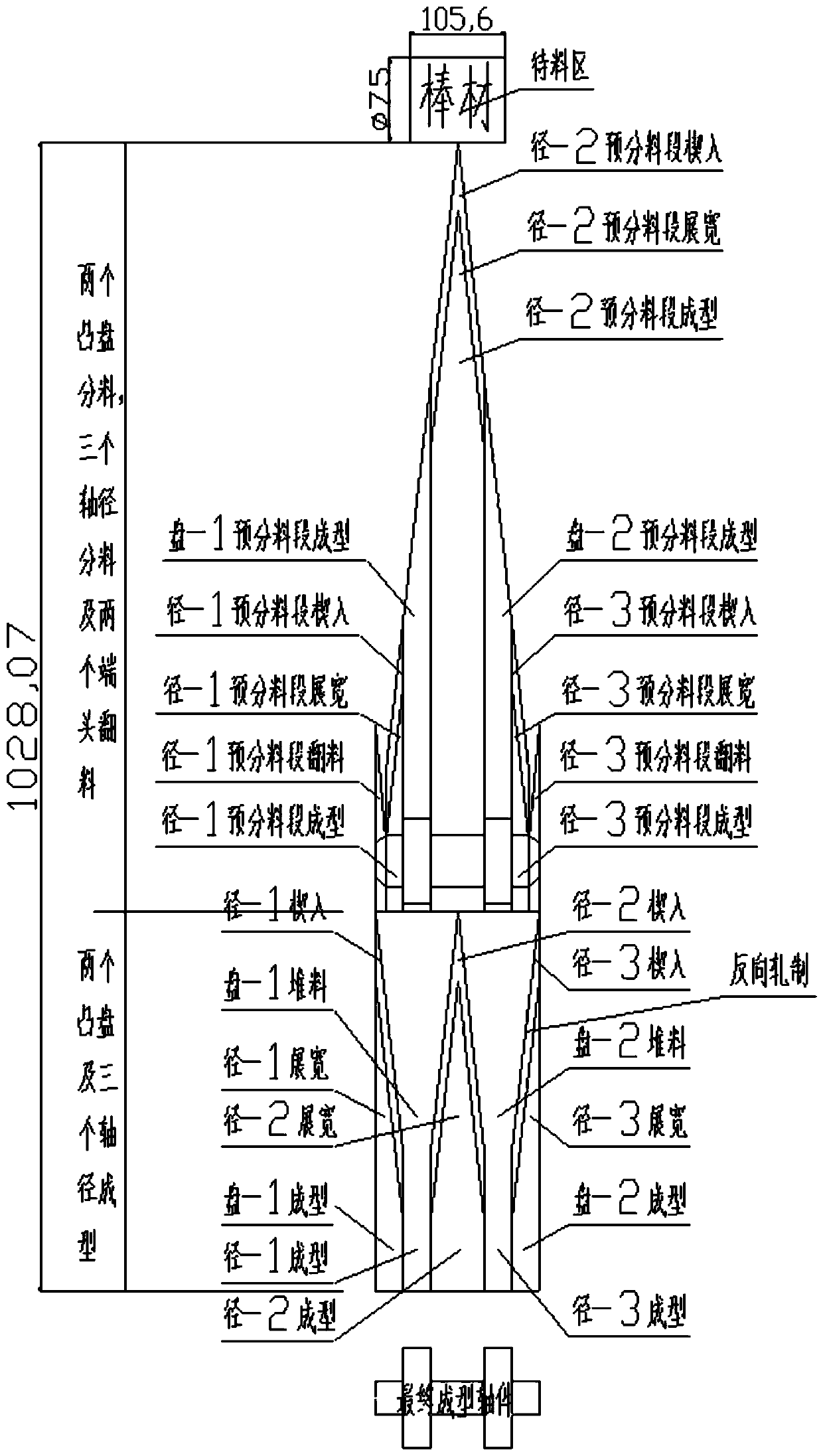

[0023] When the present invention is actually implemented, it is a cross-wedge rolling technology for pre-dividing and centralized molding. The product formed by the cross-wedge rolling technology includes two convex disks distributed along the axial interval, which are respectively disk-1 and disk-2. The disk-1 and the disk-2 are connected by the shaft diameter of diameter-2, the shaft diameter of diameter-1 is set on the upper left side of the disk-1, and the diameter-1 is arranged on the right end side of the disk-2. 3 shaft diameter.

[0024] The process steps of cross wedge rolling technology include:

[0025] (1) The bar to be processed is taken, and the bar is heated by a medium-frequency induction diathermy electric furnace. The heating temperature is controlled at 1000°C±10°C, so that the surface of the rolled part is smooth and uniform, with less oxidation, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com