Patents

Literature

59results about How to "Low desorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing radioisotope tracer

The invention discloses a method for preparing a radioisotope tracer. The method comprises the following steps of: dissolving carbonate which contains a radioisotope by using an acid; immersing a porous carrier into a solution, absorbing an isotope ion, and then stirring at the temperature of 100 to 300 DEG C for a certain time until the porous carrier is dried; after the porous carrier is dried, fixing the isotope ion by using a precipitant, and drying at the temperature of 100 to 300 DEG C; carrying out surface treatment on the dried porous carrier, and adding a resin adhesive, an antistatic agent, temperature-resistant resin and a surfactant sequentially; and carrying out surface treatment on the porous carrier to obtain the radioisotope tracer for injection profile logging. The method is simple and convenient to operate; the prepared injection profile logging tracer is low and uniform in density and good in suspension property, avoids agglomeration in a water suction solution and cannot sink or float upwards; and the radioisotope tracer is low in isotope desorption rate, stable in radiation strength and low in isotope contamination, and resists high temperature of 120 DEG C and pressure of 60 MPa.

Owner:河南省同新科技有限责任公司

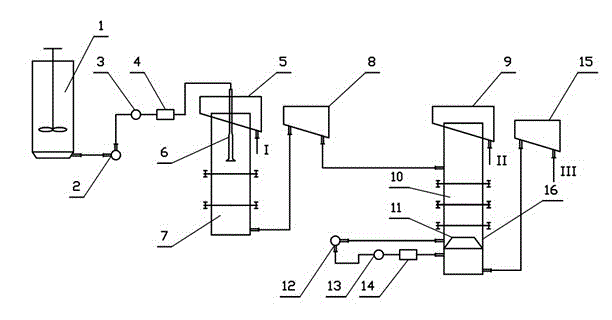

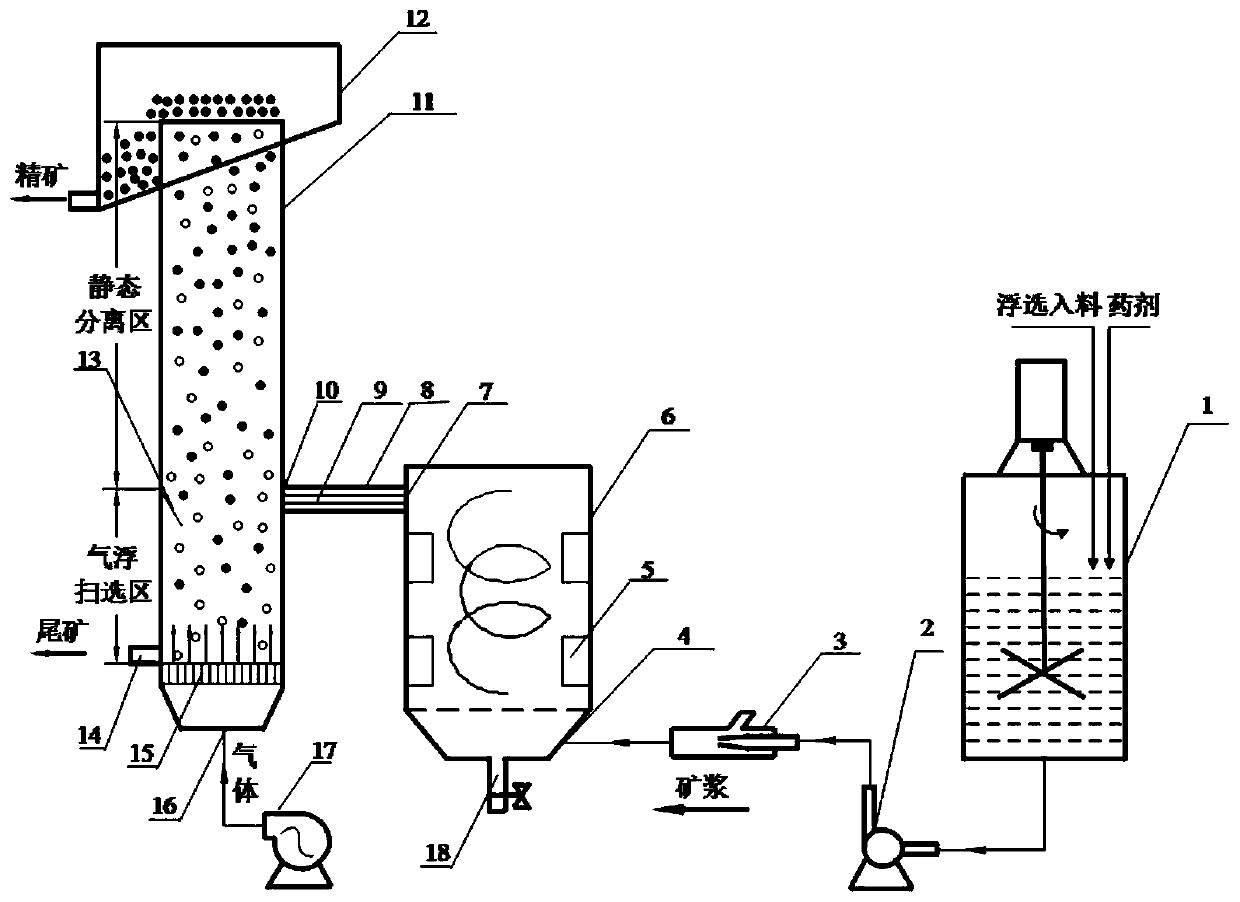

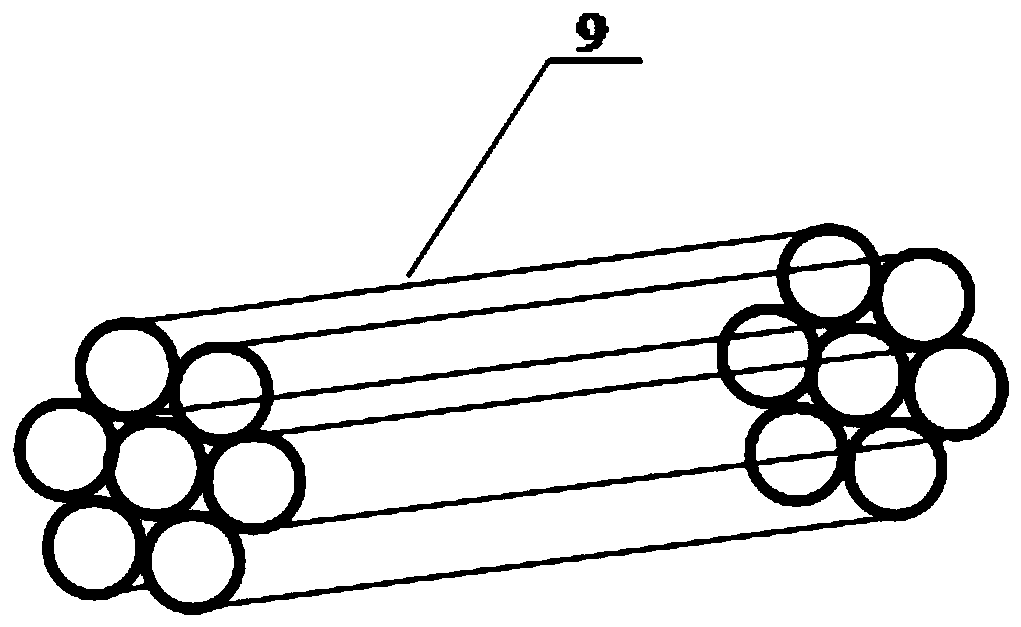

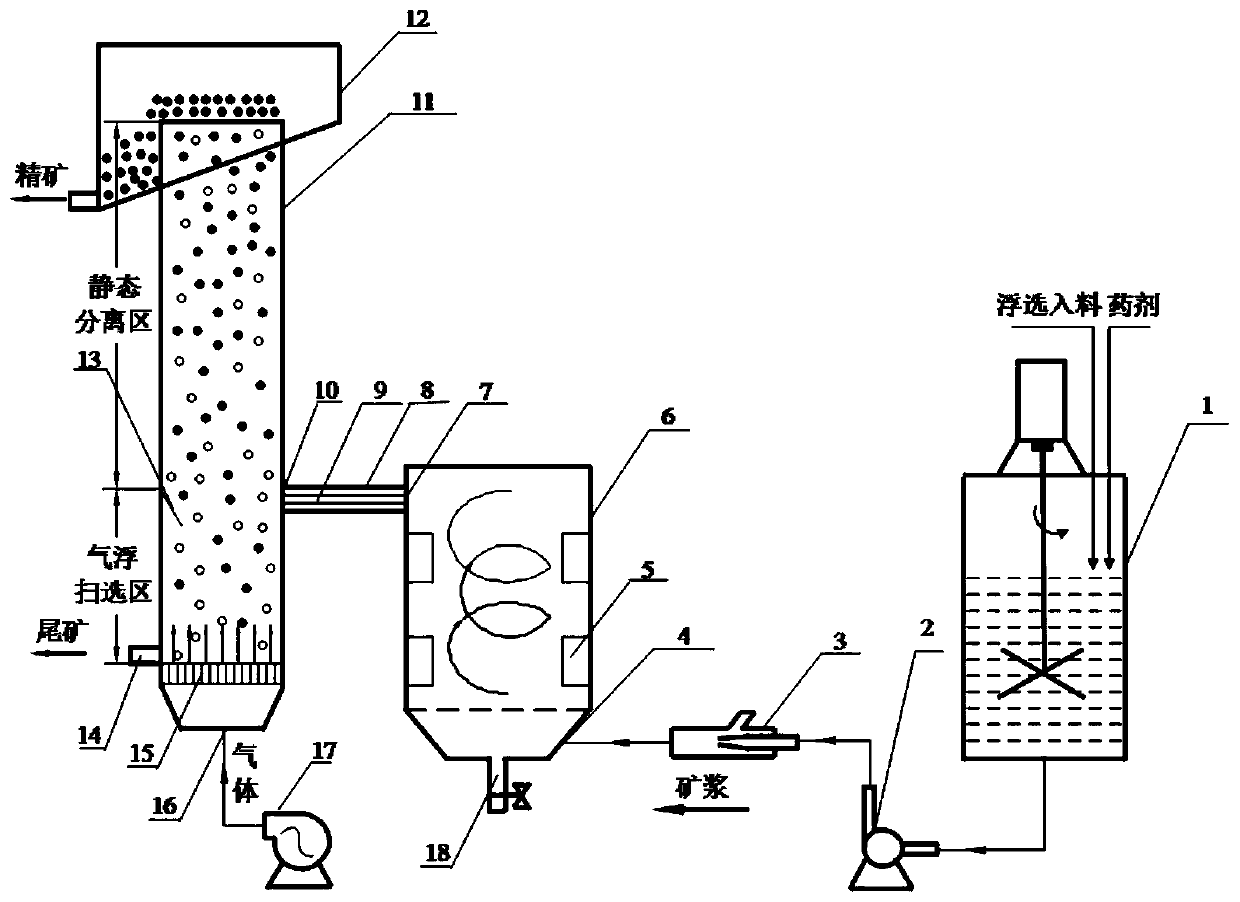

Novel flotation column serial connection test system for improving flotation granularity upper limit

The invention relates to a novel flotation column serial connection test system for improving the flotation granularity upper limit. The equipment of the system comprises a fed material stirring barrel, a feeding pump, a feeding pressure meter, a froth generator, a primary-section foam enriching chamber, a lower catheter, a spray type flotation column chamber, a primary-section tailing box, a secondary-section foam enriching chamber, a column flotation chamber, a rotary flow sorting chamber, a circulation ore pulp pump, a circulation pressure meter, a froth generator, a secondary-section tailing box and an FCMC cyclo-microfroth flotation column, wherein a spray type flotation column and the FCMC cyclo-microfroth flotation column are connected in series by the system, and the primary-section tailing is used as secondary-section fed materials. The system is favorable for the static fast flotation of preference flotation of coal with good flotation performance and the strong power efficient recovery of difficult-to-sort coal, in addition, the problem of high-concentration coal slime flotation can be perfectly solved, the recovery rate of coarse particle coal slime can be improved, and the problem of coarse particle running of coarse particle flotation can be solved.

Owner:CHINA UNIV OF MINING & TECH

Preparation method of rice husk based porous carbon fungaltoxin adsorbent

ActiveCN102847512ASimple preparation processLow costOther chemical processesFood processingPorous carbonDesorption

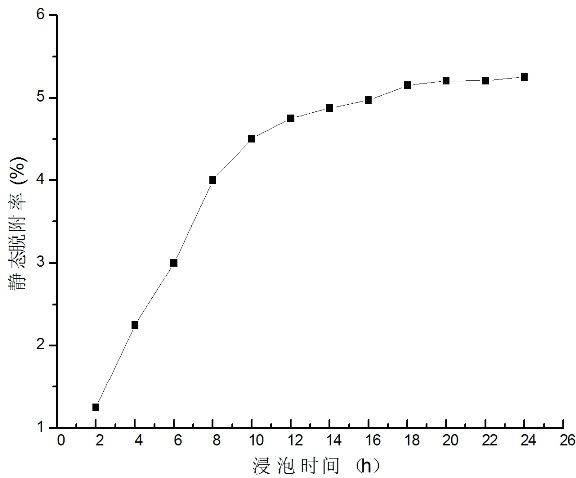

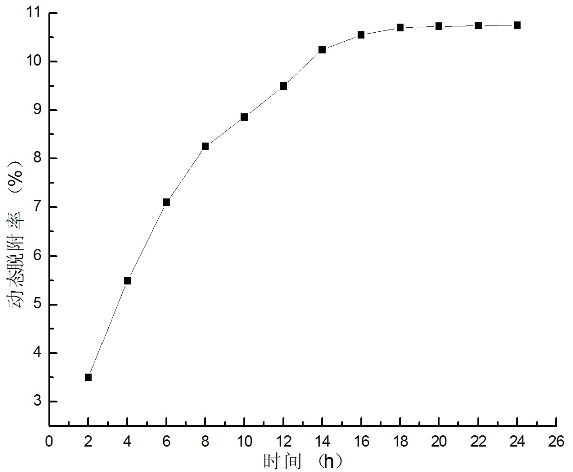

The invention discloses a preparation method of a rice husk based porous carbon fungaltoxin adsorbent. The preparation method uses rice husks to serve as raw materials, immersion treatment is carried out by using aqueous alkali in certain concentration through low temperature pre-carbonization, and finally firing is carried out under a condition that air is isolated to generate end products of the adsorbent. In a scope from acidic property to neutral, when the concentration of various fungaltoxins is as high as 1mng / mL, removing rate of rice husk based porous carbon on the various fungaltoxins is higher than 98%, adsorption is stable, and desorption rate in 8h is all lower than 5%, so that the rice husk based porous carbon is an excellent fungaltoxin adsorbent. The rice husk based porous carbon is safe, non-toxic and low in content of impurities such as heavy metal, and is an ideal adsorbent product for removing fungaltoxin pollution in foods and feeds.

Owner:JIANGNAN UNIV

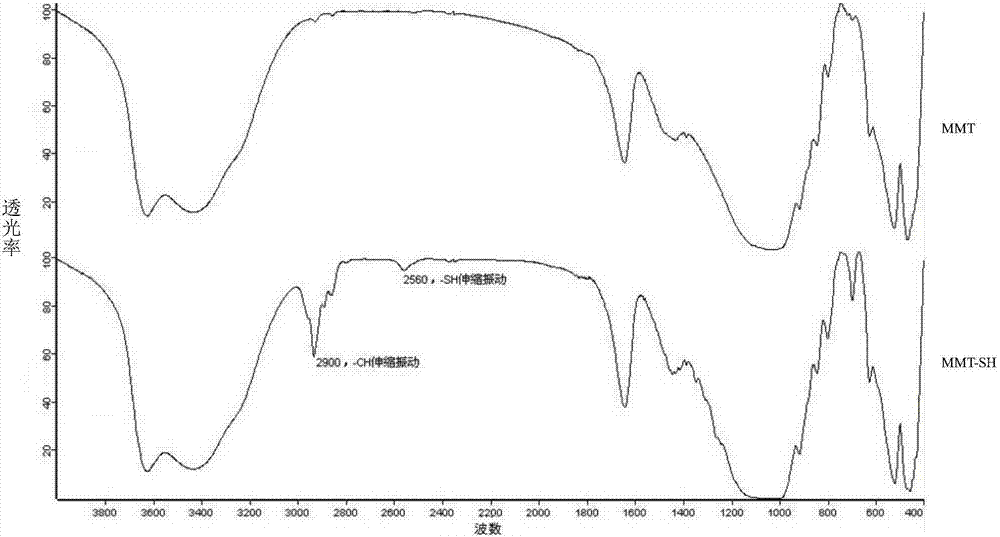

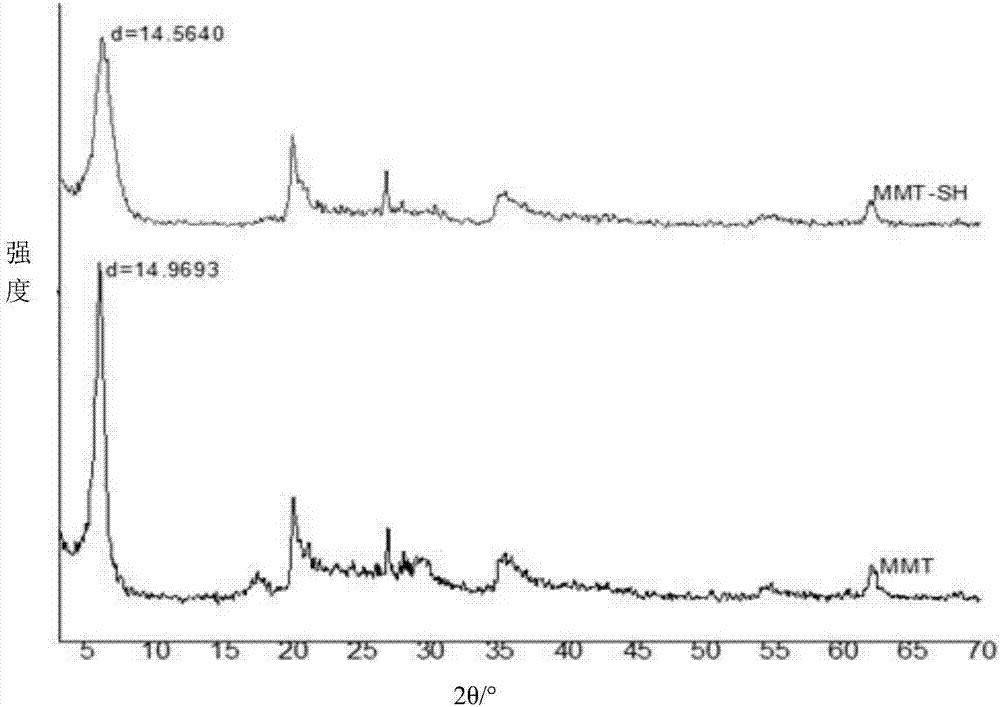

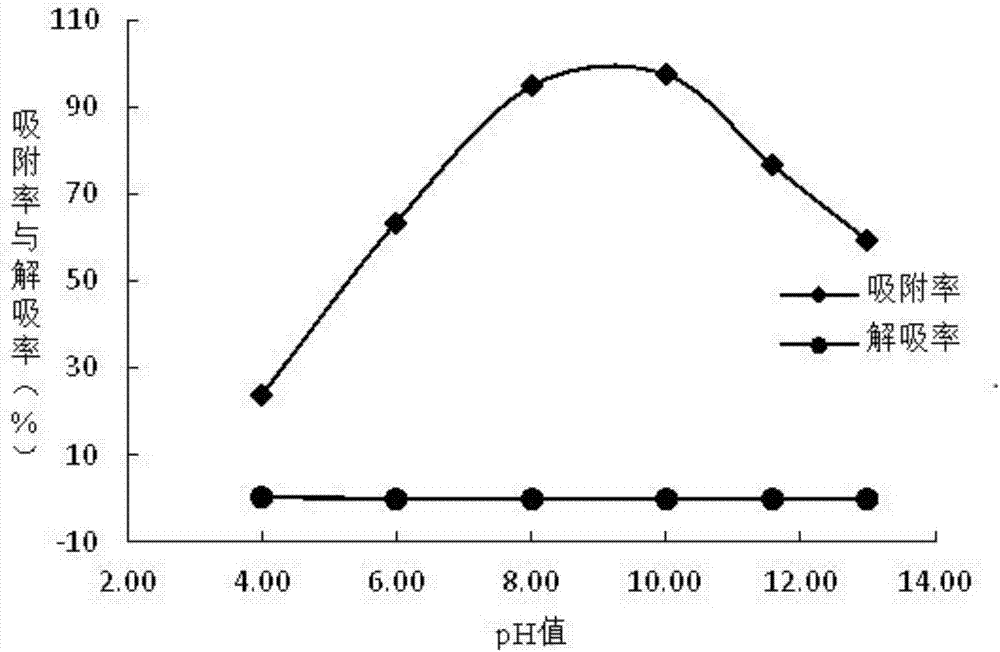

Thiolated bentonite for remedying heavy metal polluted soils and preparation method thereof

ActiveCN107011918ALow costGood value for moneyAgriculture tools and machinesOrganic fertilisersThiolSodium Bentonite

The invention relates to the technical field of heavy metal polluted soil controlling and remedying, and in particular relates to thiolated bentonite for remedying heavy metal polluted soils and a preparation method thereof. The preparation method comprises the steps of mixing bentonite, ethanol solution of 3-mercaptopropyl trimethoxy silane, sodium silicate with water, stirring, reacting, washing, filtering and drying to obtain the thiolated bentonite. The obtained thiolated bentonite is low in price, high in adsorption rate, low in desorption rate and large in adsorption capacity. The preparation method has the advantages that the using amount of thiol modifier is reduced by a large margin, so that the cost is reduced; and the modification is carried out on original bentonite, so that the modifying process is simplified.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +1

Mineralization-flotation separation column sorting device and method

ActiveCN109759243AImprove recycling effectIncrease the probability of collisionFlotationFlocculationSlurry

The invention provides a mineralization-flotation separation column sorting device and method, which are applicable to ore processing. The mineralization-flotation separation column sorting device comprises a stirring barrel, a pump, a bubble generator, a mineralization chamber, a flocculation elimination pipe, a flotation column and an air compressor; after flotation ore slurry is mixed through slurry blending equipment and passes through the bubble generator, the ore slurry enters the cyclone mineralization chamber; the ore slurry which is rotated at a high speed and bubbles are subjected tohigh-strength turbulent flow collision and mineralized bubbles are formed; a large vortex of the mineralized bubbles are eliminated through the flocculation elimination pipe and then the mineralizedbubbles enter a flotation column static sorting region to finish static separation; a flotation assisting baffle plate is arranged at the bottom of the flotation column static separation region and the ore slurry is prevented from entering tailings due to short circuiting; ore grains which are not mineralized and desorbed are subjected to intensive recovery; low-ash clean coal is recycled and high-ash ores are discharged from a tailing opening. According to the mineralization-flotation separation column sorting device, the flotation and falling probability of low-ash coarse grains is effectively reduced and the equipment processing capability is great; the device has strong adaptability on different coal properties, low production and operation cost and is convenient to mount and operate;the quantity and quality of clean coal products are wholly improved.

Owner:CHINA UNIV OF MINING & TECH +2

High ash fine grain coal slurry separation equipment and method

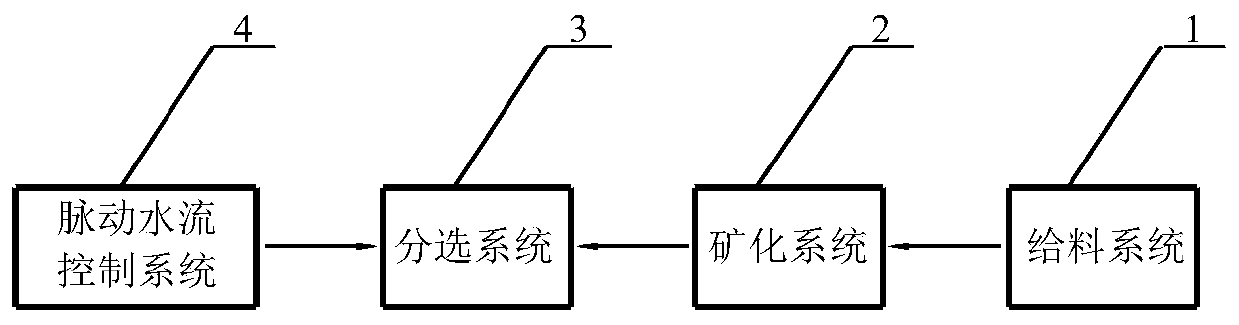

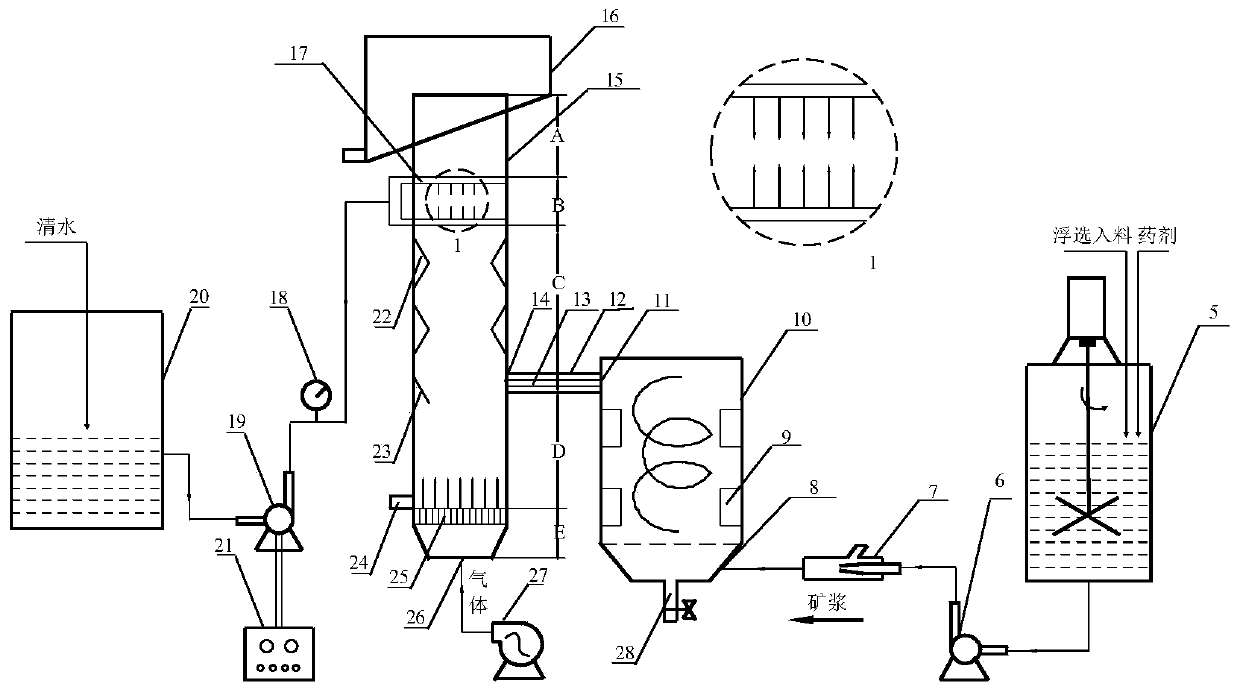

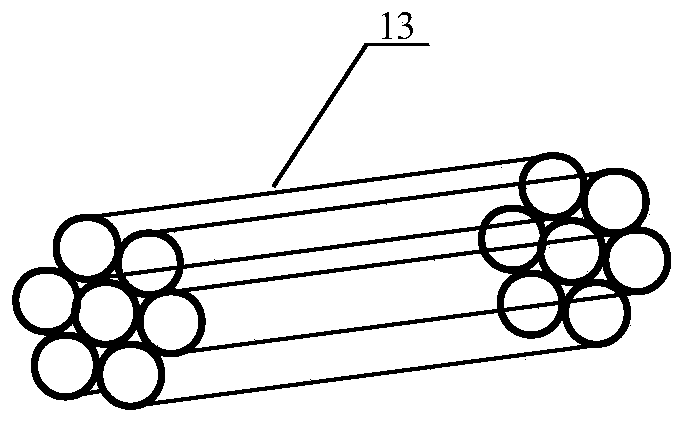

ActiveCN109759242AImprove recycling effectIncrease the probability of collisionSeparation devicesFlotationControl systemWater flow

The invention provides a high ash fine grain coal slurry separation equipment and method which areapplicable to the field of coal washing. The separation equipment comprises four parts, specifically afeeding system, a mineralization system, a separation system and a pulse water flow control system. The equipment is characterized in that a coal slurry mineralization area is separated from a separation area, and the ore separation system is internally provided with a damping block and a pulse water flow device. Flotation materials are fed into the feeding system, the size mixing operation is completed, coal slurry subjected to size mixing enters the mineralization system to be subjected to turbulent collision, mineralized bubbles are formed, the mineralized bubbles enter the separation system after passing through a disorder eliminating pipe, meanwhile the pulse water flow control system supplies the separation system with pulse water flows with certain frequency and waveform, the finecoal ash content is lowered, and the coal slurry separation selectivity is improved. Recycling of low ash coarse particles is effectively improved, high ash thin slurry carried by water flow and the thin slurry covering the surface of the particles are beneficially reduced by means of the damping block and the pulse water flow effect, and the separation selectivity is improved. The equipment has high coal slurry adaptability on different coal qualities, the separation effect is good, the separation efficiency is high, the production operation cost is low, and the economical benefit is outstanding.

Owner:CHINA UNIV OF MINING & TECH +1

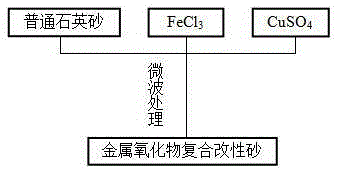

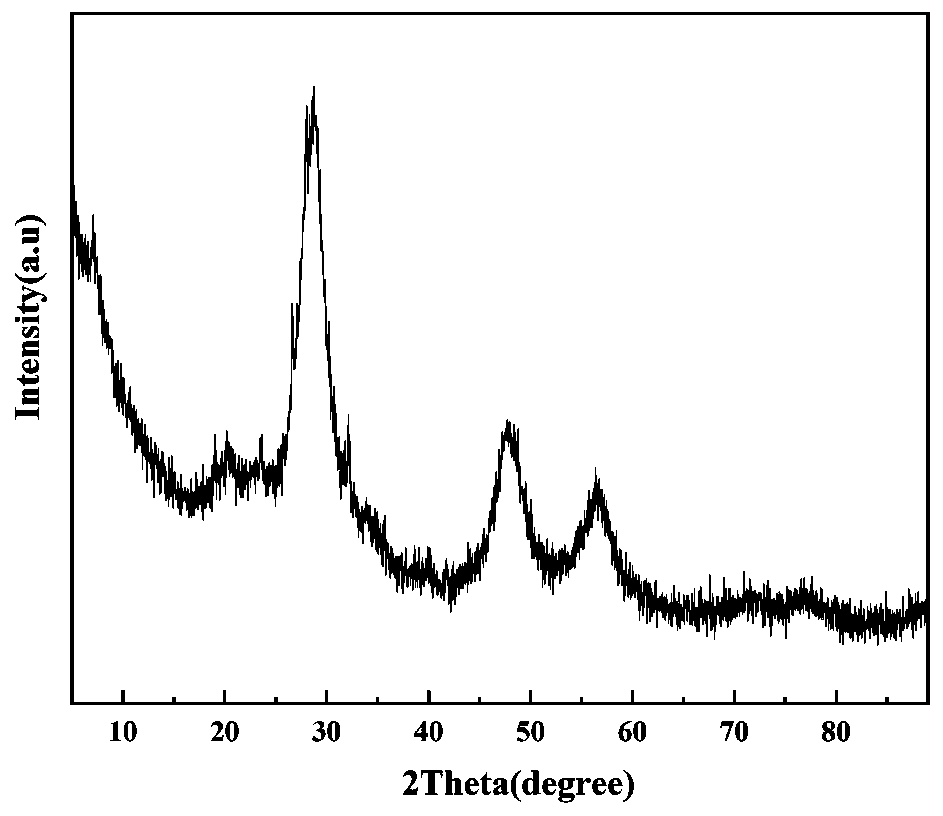

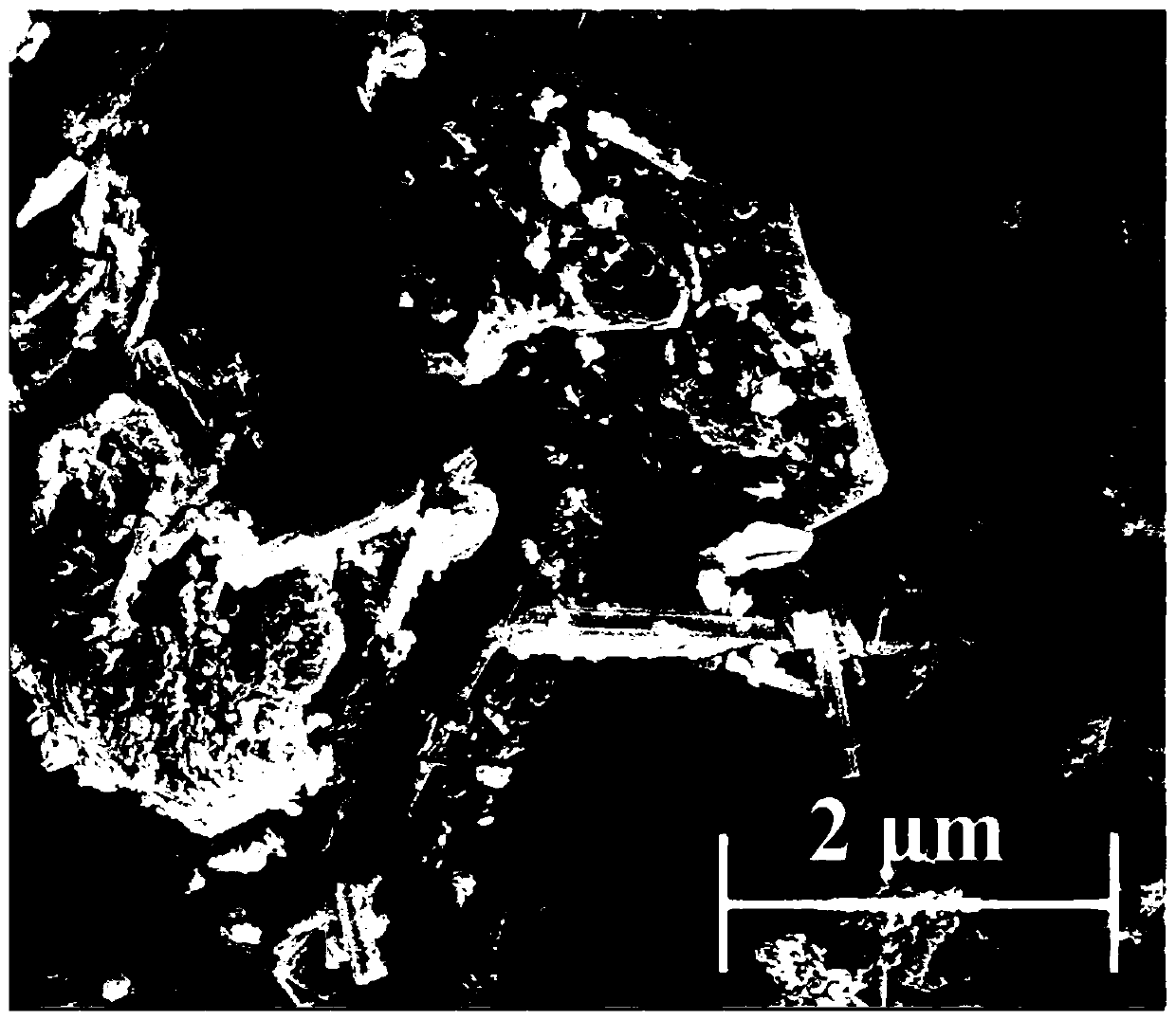

Novel metal oxide iron-copper composite modified quartz sand filter material, and preparation method and application thereof

InactiveCN105233570AHigh adsorption capacityReduce energy consumptionOther chemical processesFiltration separationHumic acidHeavy metals

The invention discloses a novel metal oxide iron-copper composite modified quartz sand filter material, and a preparation method and application thereof. Concretely, the metal oxide iron-copper composite modified quartz sand filter material is prepared by modifying quartz sand with ferric trichloride and copper sulfate as modifying agents by adopting a microwave technology at the same time. The metal oxide iron-copper composite modified quartz sand filter material prepared by using the method in the invention can effectively adsorb organic and inorganic pollutants, heavy metals, phosphorus, etc. in water; the material has a specific surface area which is 8.96 times of the specific surface area of ordinary quartz sand, and has larger adsorption capacity than the ordinary quartz sand; a removal rate of the material to humic acid is 96.58% and is increased by 67.86% than the removal rate of the ordinary quartz sand to the humic acid; and the removal rate of the material to the phosphorus in water is 71.5% to 96.23%. Moreover, the modified quartz sand filter material has higher adhesion strength to pollutants and is reduced in desorption rate to surface metals; meanwhile, the material has low production cost and investment cost and is convenient for industrial production.

Owner:GUANGDONG UNIV OF TECH

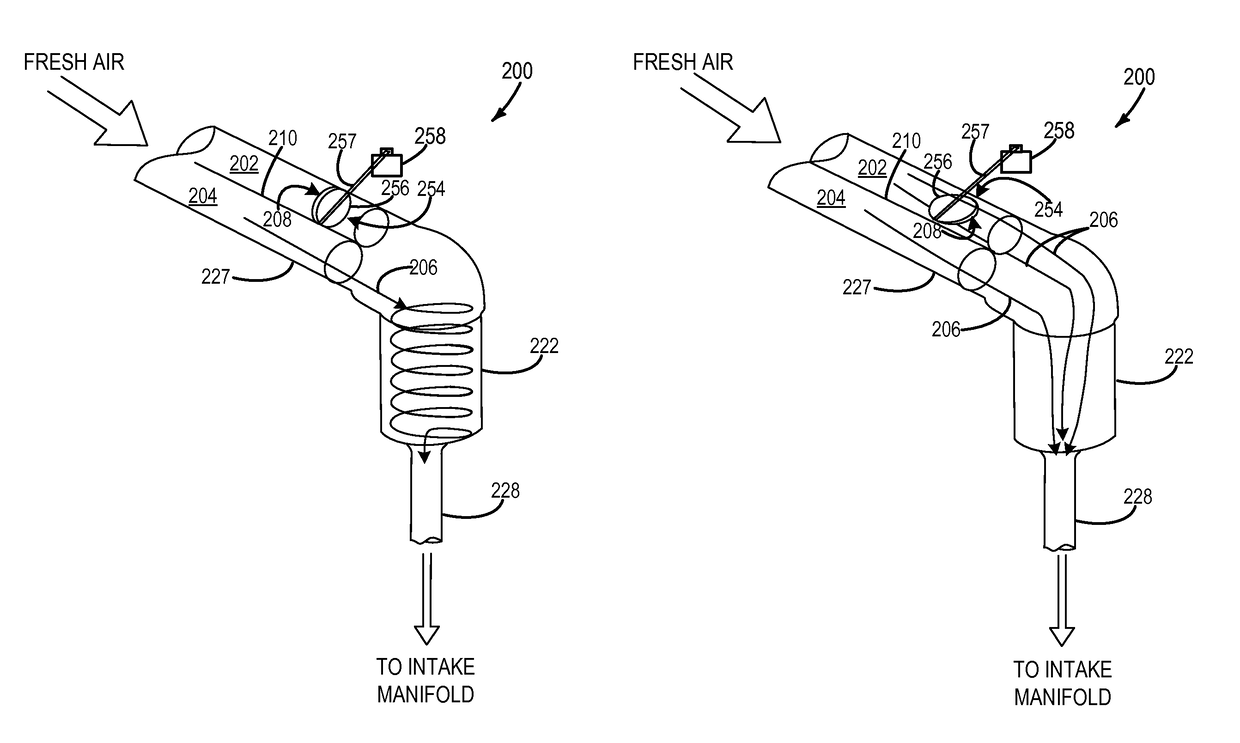

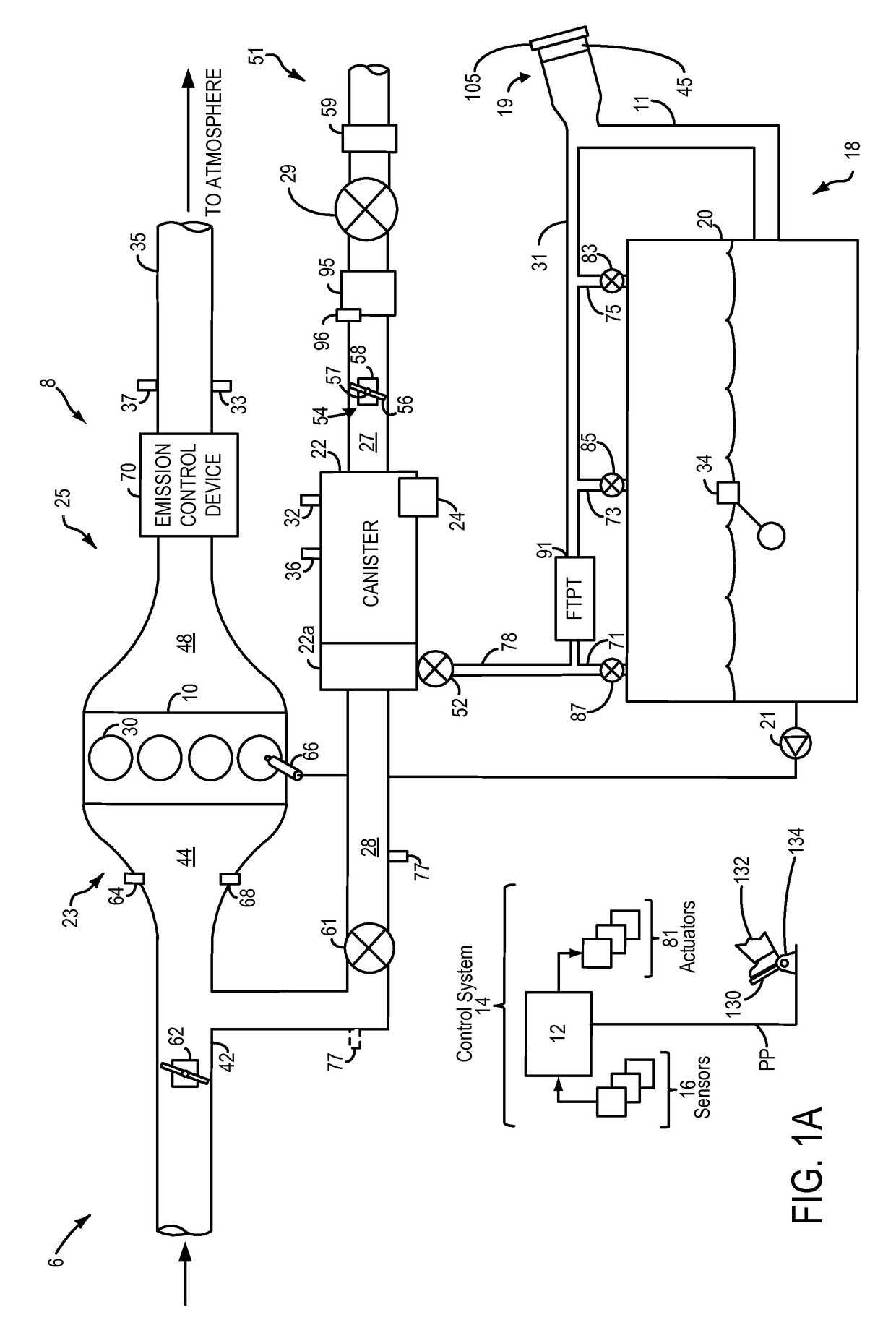

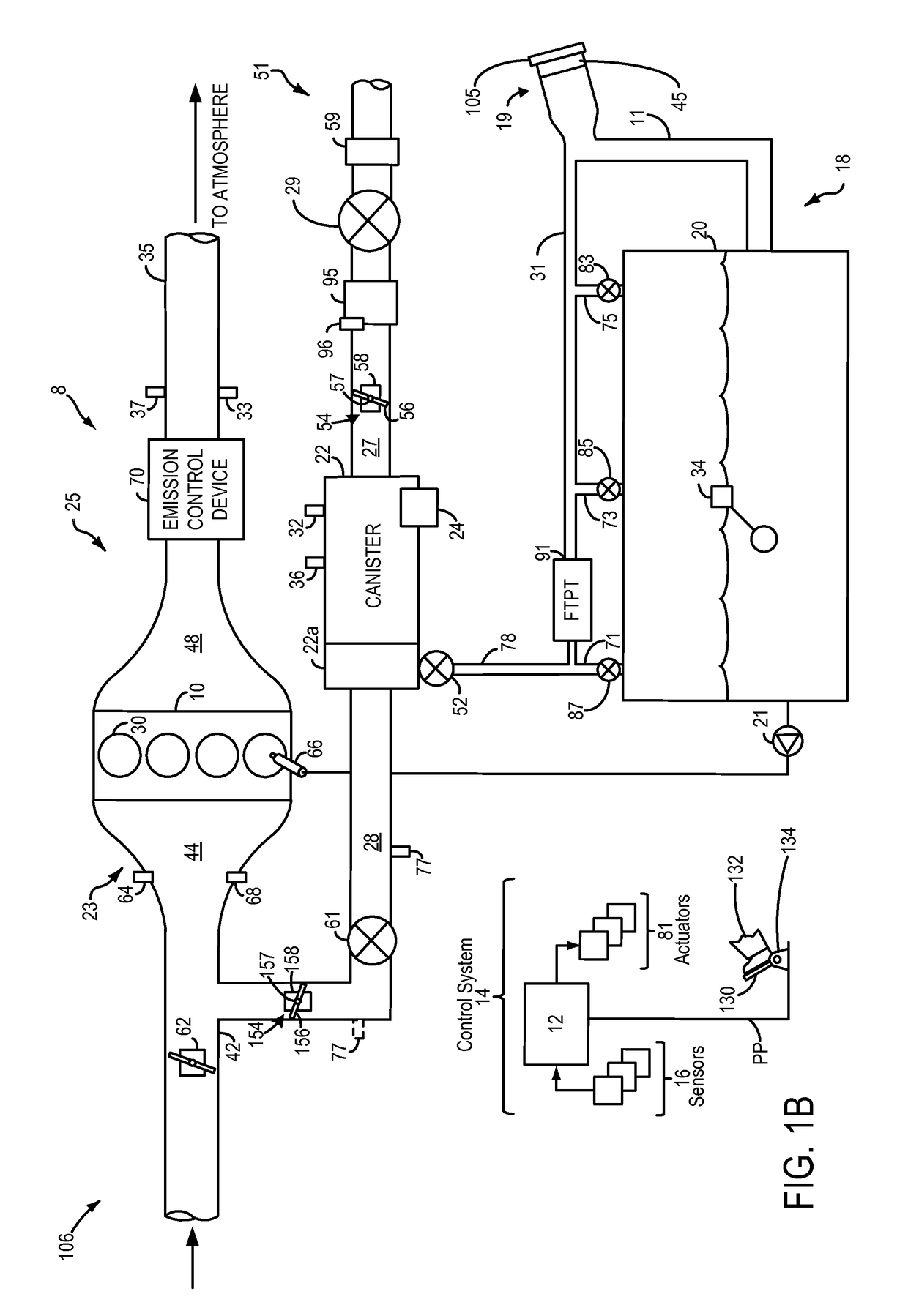

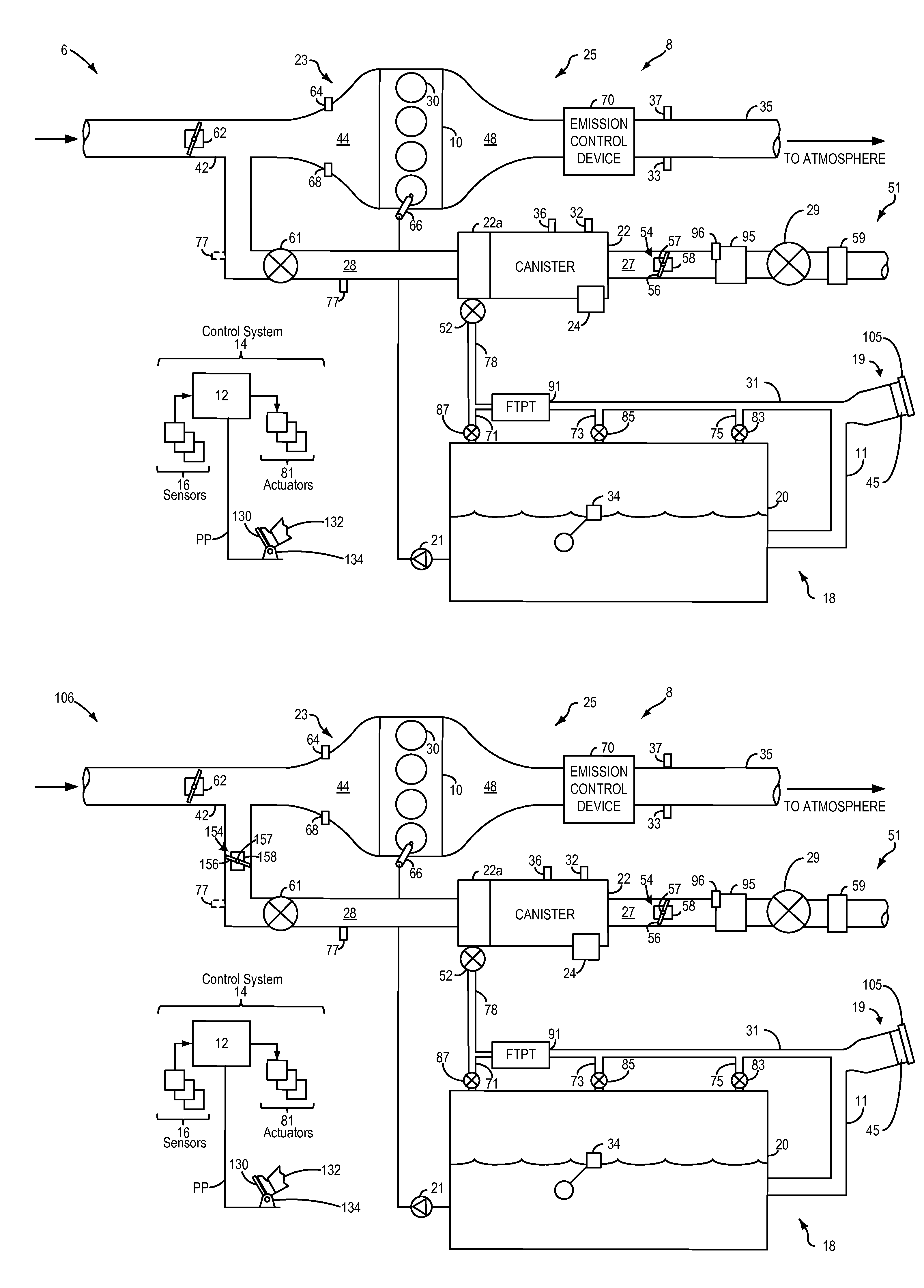

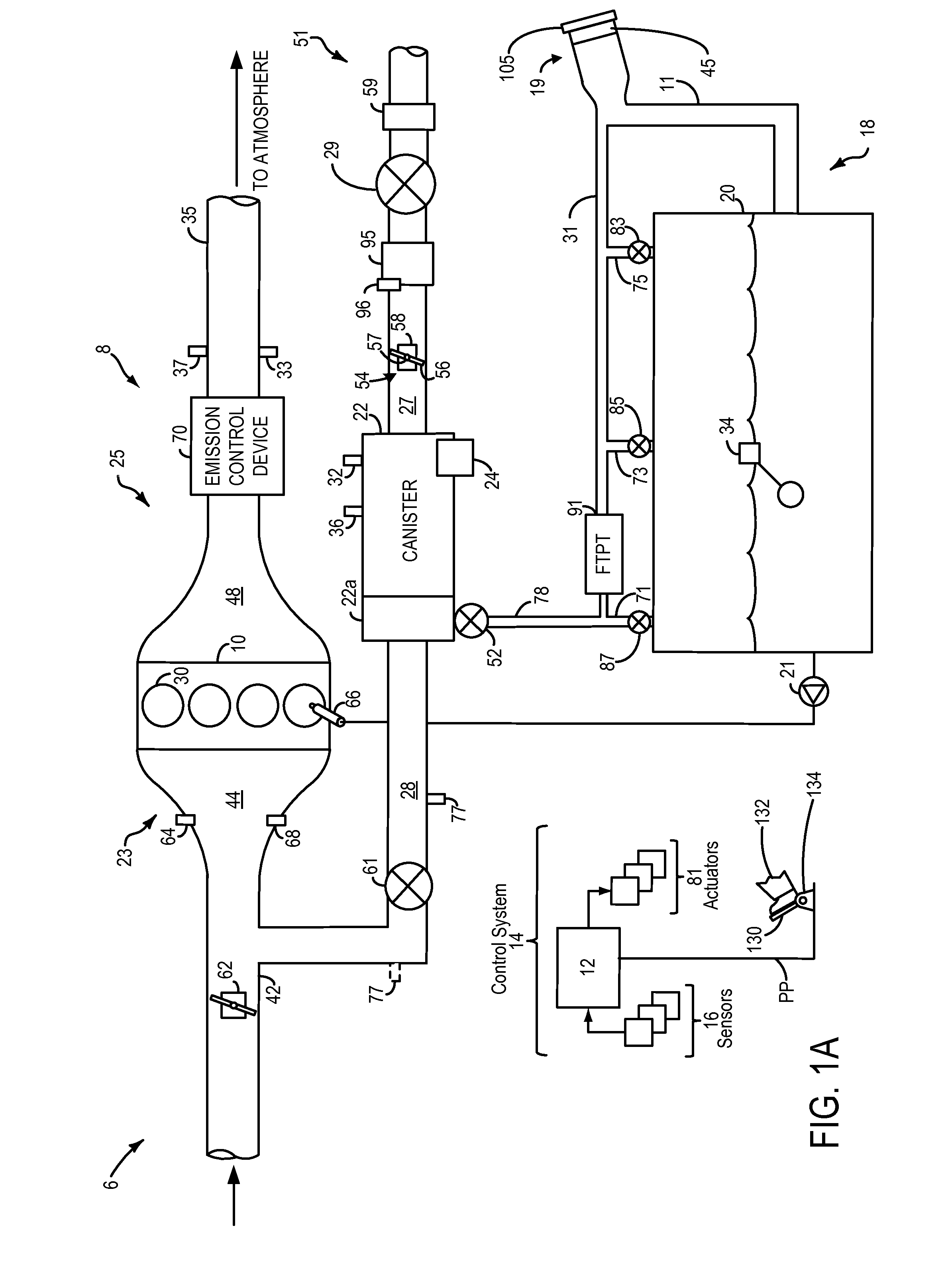

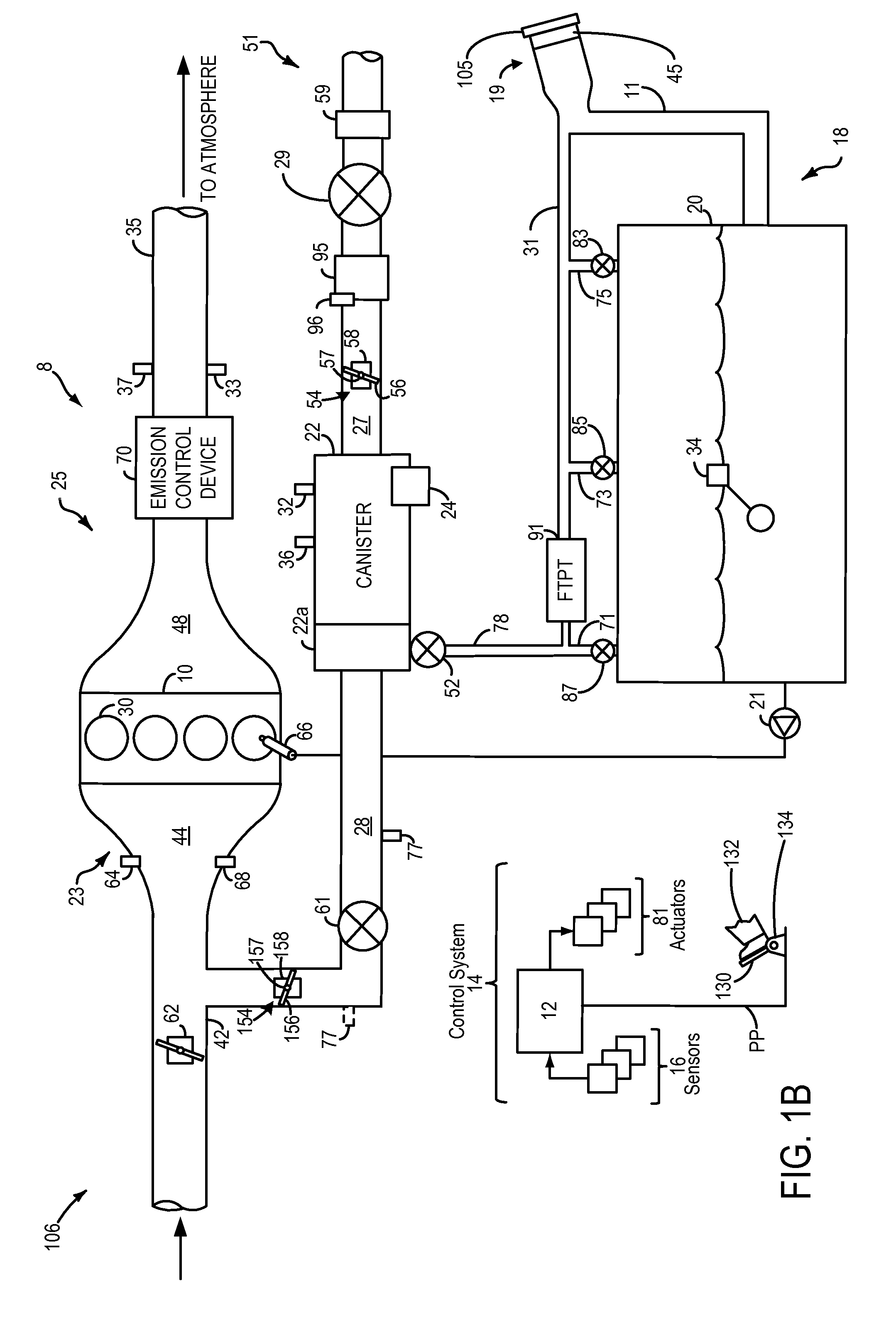

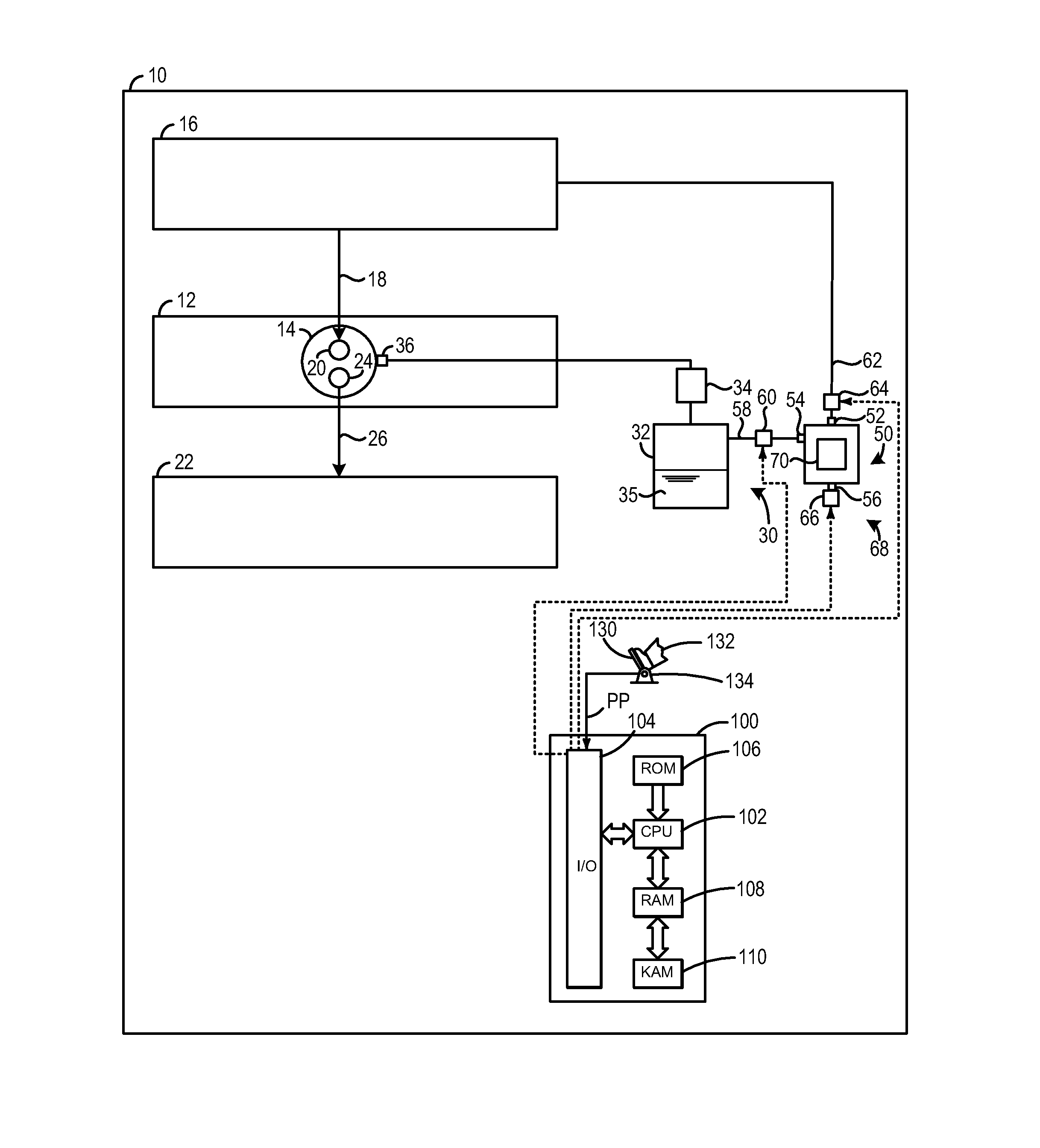

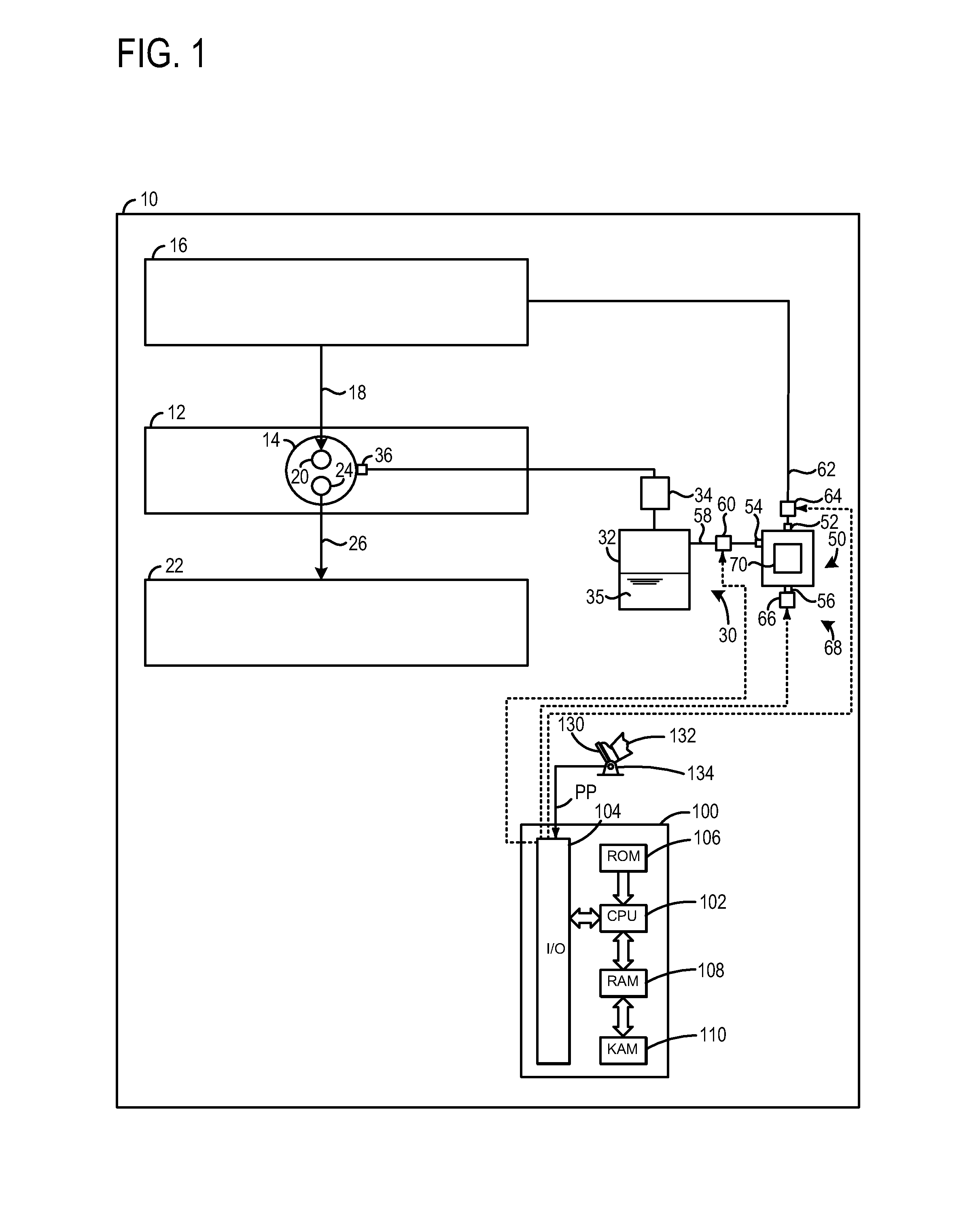

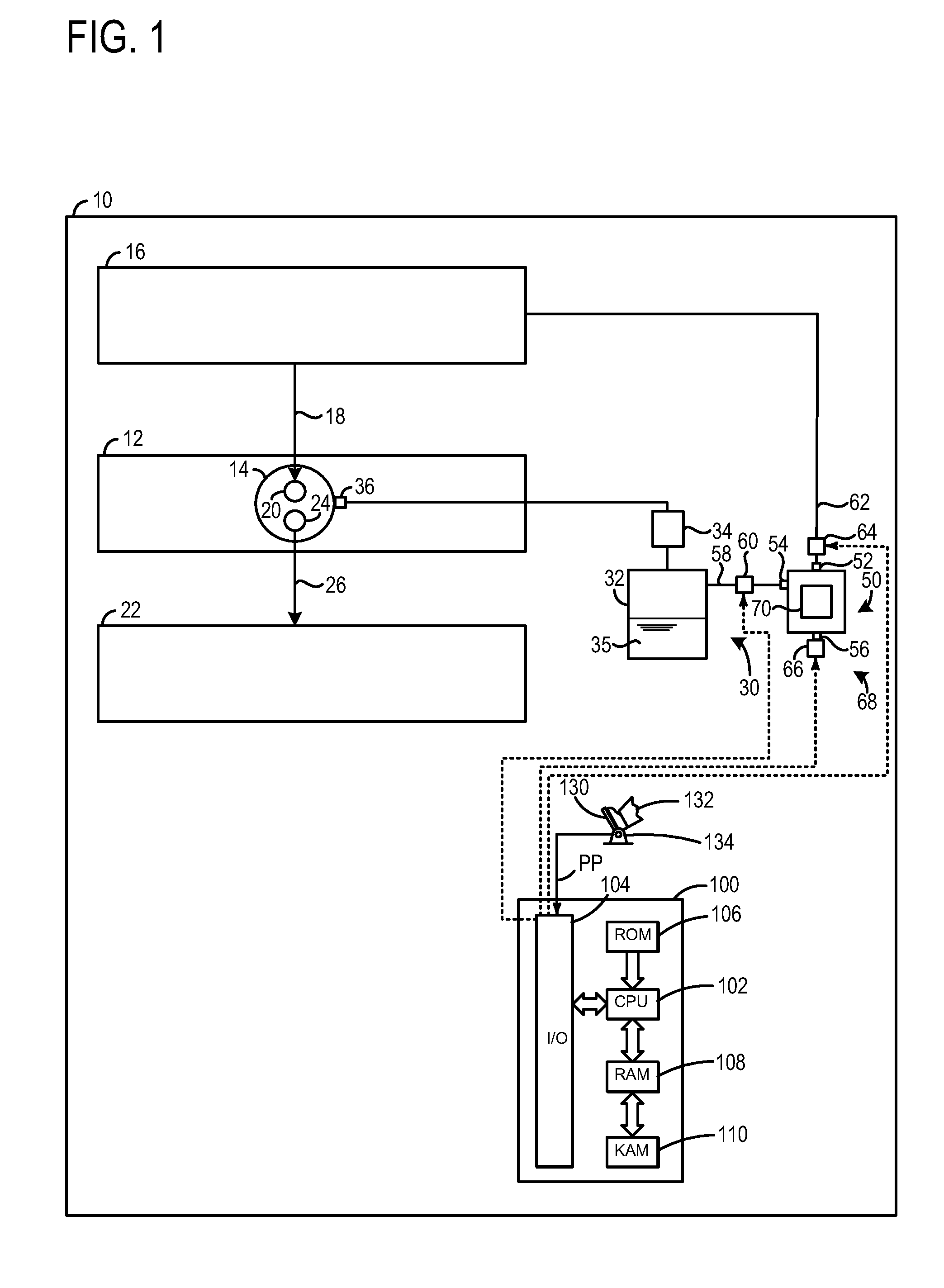

EVAP system with valve to improve canister purging

InactiveUS9845745B2Increase pressureAccelerate emissionsElectrical controlNon-fuel substance addition to fuelControl systemActuator

Systems and methods are provided for an evaporative emissions control system. In one example, a system for an engine may comprise a fuel vapor canister, a mixing valve positioned in a fresh air line upstream of the vapor canister, and an actuator physically coupled to the mixing valve for adjusting a position of the mixing valve to increase turbulence in air entering the vapor canister. The position of the mixing valve may be adjusted to increase an amount of turbulence in air entering the fuel vapor canister.

Owner:FORD GLOBAL TECH LLC

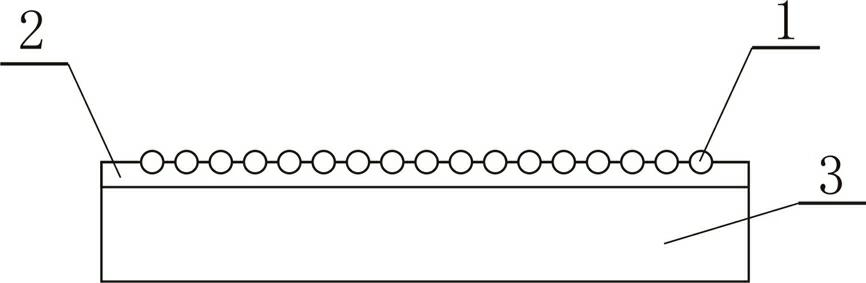

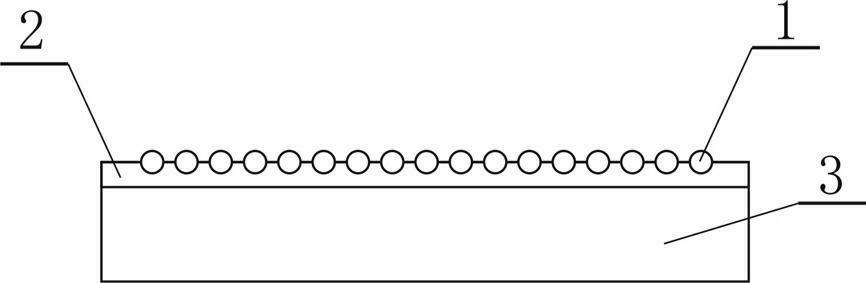

Nanoparticle photocatalysis board, its preparation method and application thereof

InactiveCN102513074AReduce manufacturing costGood effectInorganic/elemental detergent compounding agentsLaminationNanoparticle coatingDesorption

The invention provides a nanoparticle photocatalysis board, its preparation method and application thereof. The nanoparticle photocatalysis board comprises a substrate and a photosensitive nanoparticle coating that is cured on the substrate. The preparation method consists of: subjecting the substrate to ultrasonic cleaning and drying it in the air, and applying a light curing adhesive uniformly in a darkroom environment, then conducting drying treatment so as to obtain a light curing rubber board; spraying the photosensitive nanoparticles on the light curing rubber board uniformly, then placing it in an ultraviolet light environment for curing, thus obtaining the nanoparticle photocatalysis board, which can be applied in removing residual washing agents in washed clothes. The photocatalysis board provided in the invention has the advantages of low preparation cost, low particle desorption rate, current scour resistance, and no loss of the activity of the nanoparticles. The method of the invention is simple and operated at normal temperature, and it reduces the cost as well as improves production efficiency.

Owner:YUNNAN UNIV

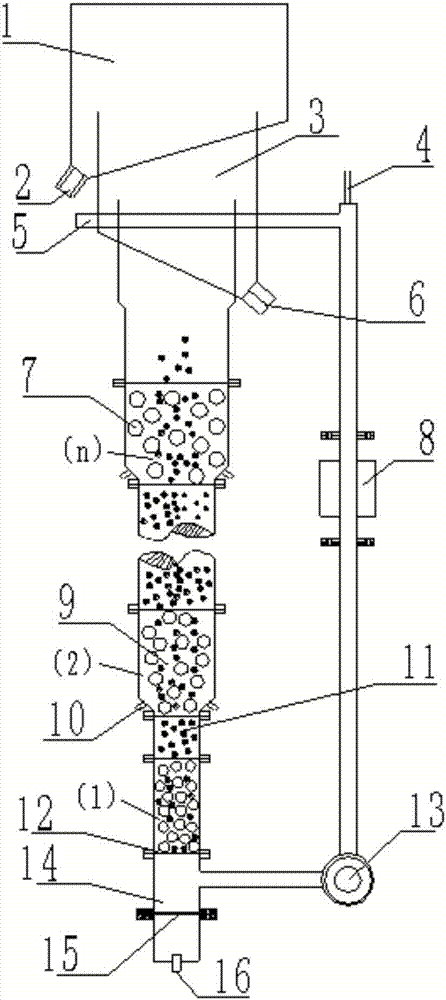

Turbulent flow regulating and controlling external particle fluidized bed mineralizing and floating device uniform in turbulence degree

ActiveCN106944264ASize balanceHigh kinetic energy utilization efficiencyFlotationFluidized bedEngineering

The invention discloses a turbulent flow regulating and controlling external particle fluidized bed uniform in turbulence degree and belongs to a mineral separation device. The device comprises a column floating area, a concentrate overflow groove in the upper portion of the column floating area and a middling ore circulating port outside the column floating area; the lower portion of the column floating area is provided with a gas and liquid mixing area; a fluidized bed mineralizing and floating area is arranged between the column floating area and the gas and liquid mixing area; the fluidized bed mineralizing and floating area is provided with a mineralizing area 1, a mineralizing area 2,... and a mineralizing area n; and the interiors of the mineralizing area 1, the mineralizing area 2,...and the mineralizing area n are filled with turbulent flow regulating and controlling particles. According to the turbulent flow regulating and controlling external particle fluidized bed uniform in turbulence degree, mineralizing and floating are totally separated, and are different from current integration of mineralizing and floating; the mineralizing time can be achieved by adjusting the mineralizing area segment number of the fluidized bed mineralizing and floating area, and therefore the kinetic energy utilizing efficiency is very high; the energy dissipating rate is high, the bubble size balance and stable retention of high-pressure gas are guaranteed, and the floating recovery rate is increased; and upper, middle and lower mineralizing fluidized bed layers are provided with different turbulence degrees, and the mineralizing efficiency is high.

Owner:CHINA UNIV OF MINING & TECH

Method for detecting polycyclic aromatic hydrocarbon in tea oil

InactiveCN106770733AImprove extraction abilityHigh enrichment factorComponent separationDesorptionCarbon nanotube

The invention discloses a method for detecting polycyclic aromatic hydrocarbon in tea oil. The method comprises the following steps: adding a magnetically hydroxylated multiwall carbon nano tube serving as a solid phase extraction reagent into the tea oil diluted by a normal hexane solvent for adsorption of a target substance, carrying out magnetic separation under the action of an external magnetic field, collecting the solid phase extraction reagent with the target substance, removing supernate, purifying the solid phase extraction reagent with the target substance through a purifier, desorbing the target substance on the solid phase extraction reagent through methylbenzene serving as a desorbent, carrying out magnetic separation under the action of the external magnetic field, removing the solid phase extraction reagent, collecting a desorption solution with the target substance, filtering the desorption solution through an organic filter film, and carrying out conventional content measurement by combining gas chromatography and mass spectrum. The method is high in selectivity, low in detection limit, high in sensitivity and high in standard recovery rate.

Owner:HUNAN ACADEMY OF INSPECTION & QUARANTINE +3

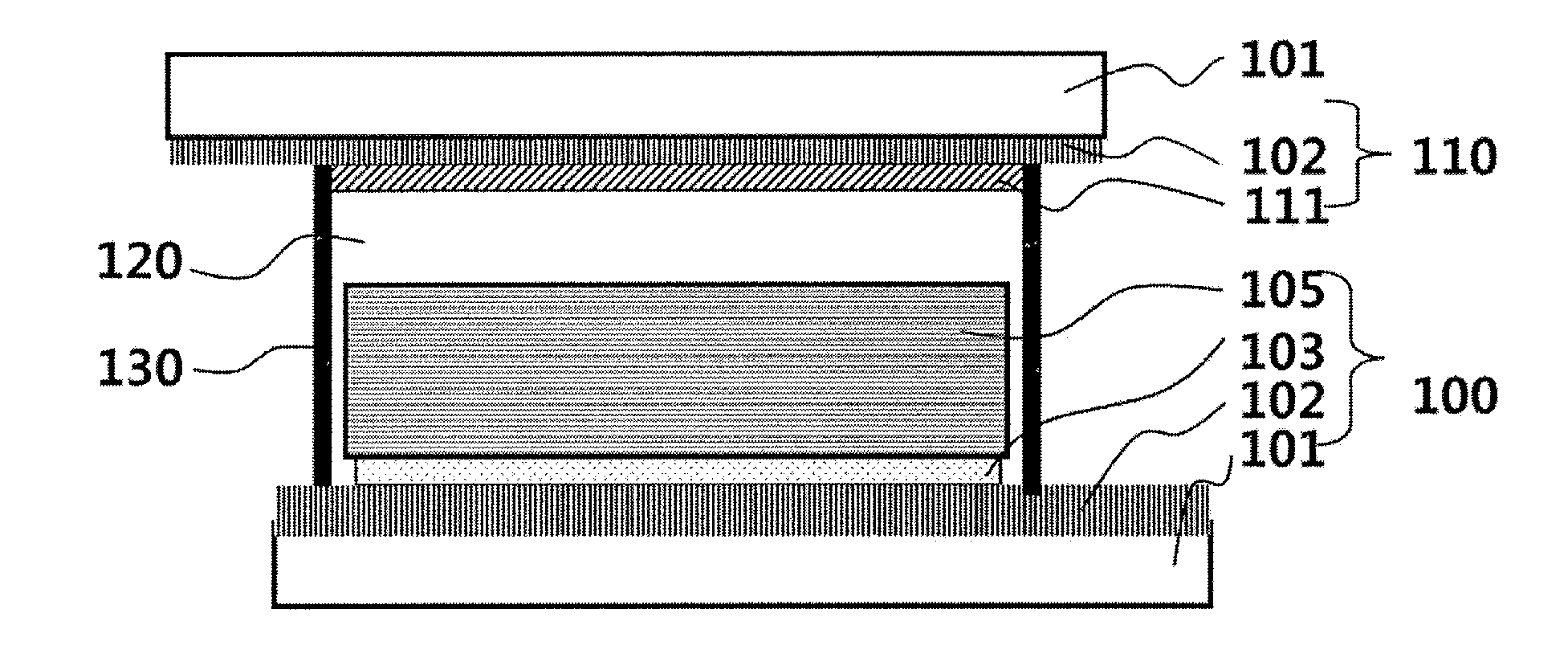

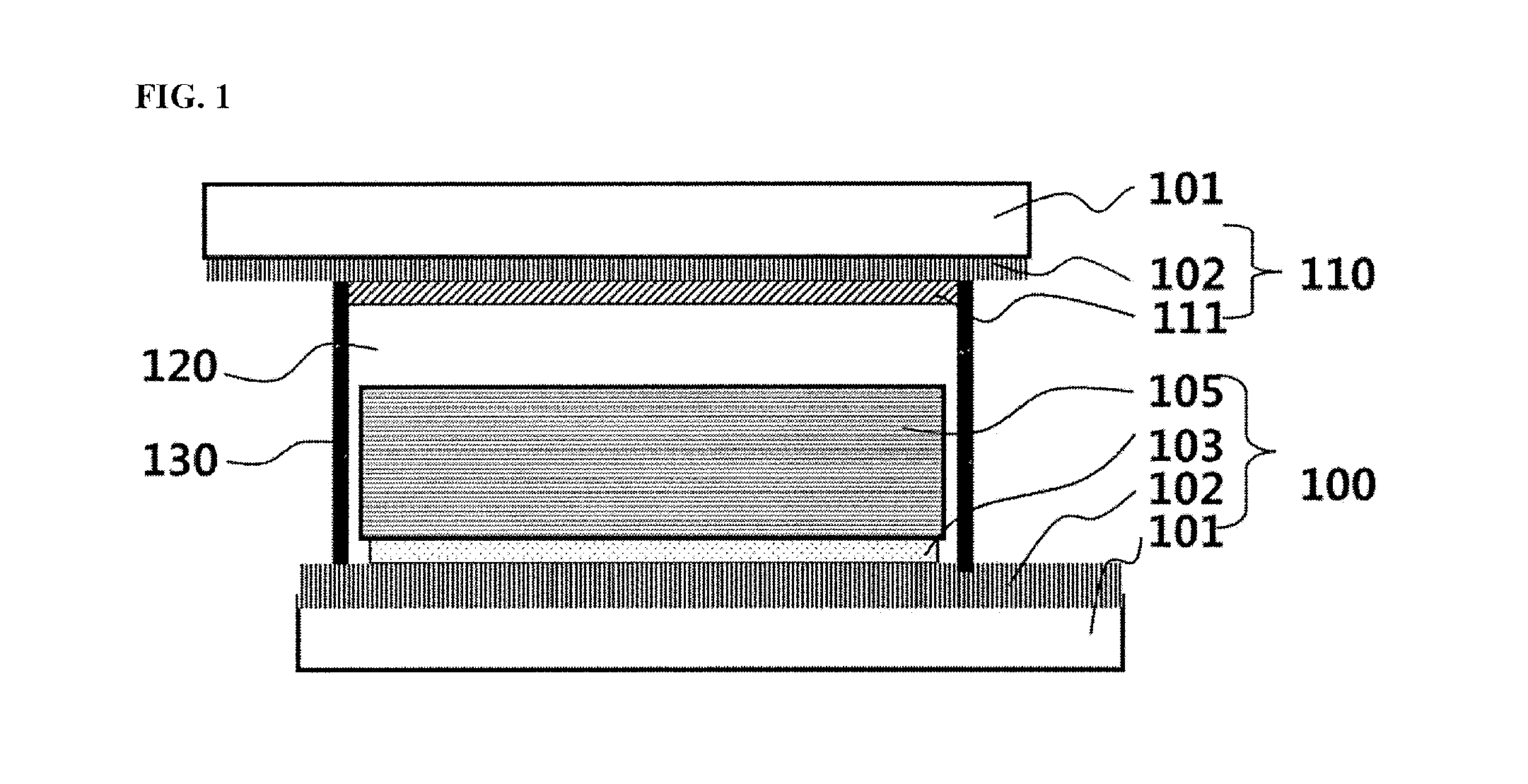

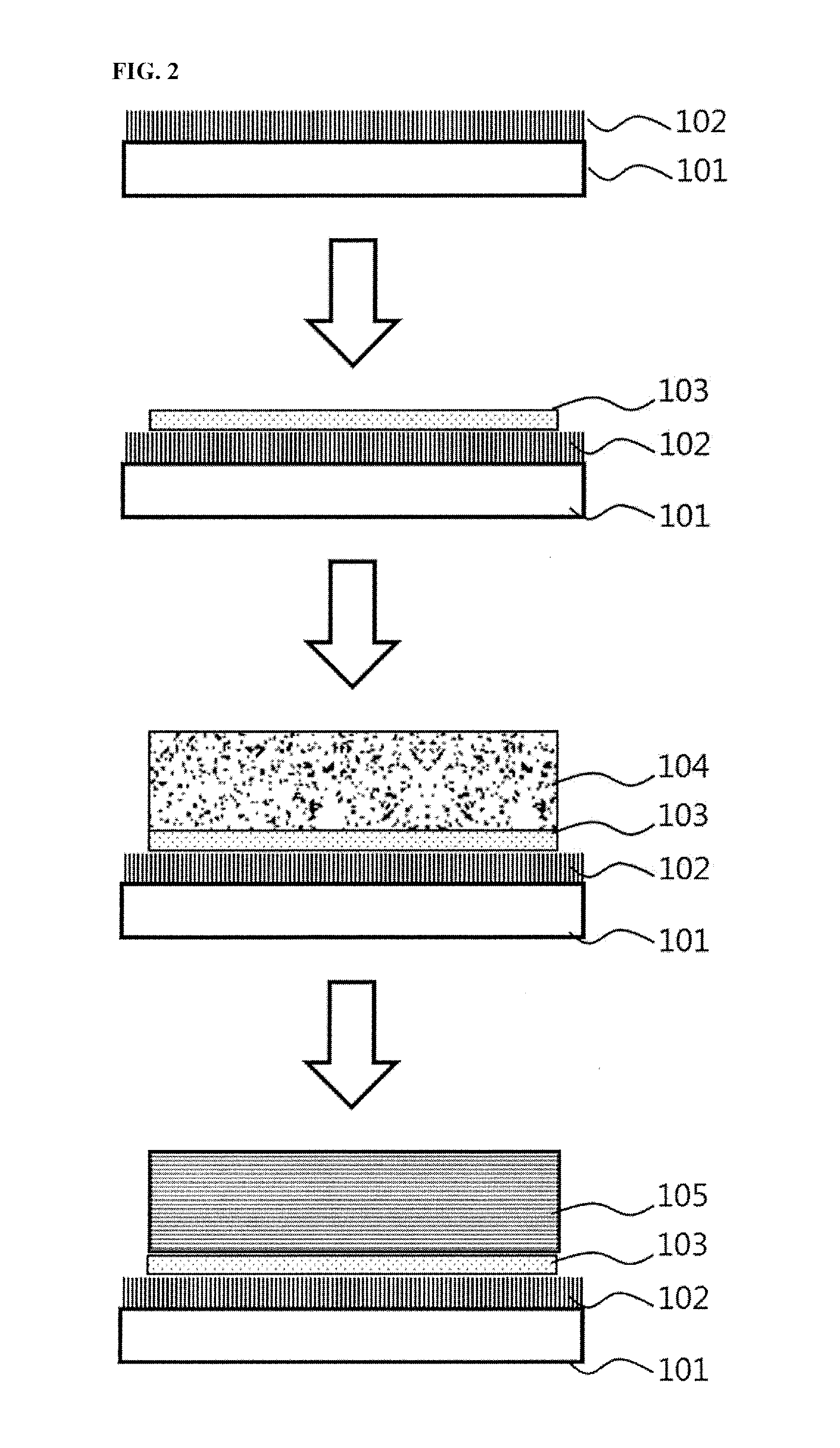

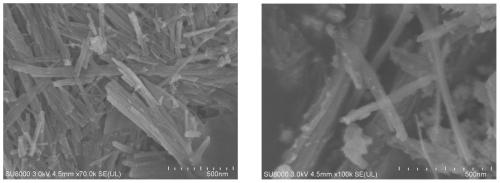

Sensitizing dye solution, working electrode for dye-sensitized solar cell prepared using the sensitizing dye solution and dye-sensitized solar cell including the working electrode

ActiveUS20150371787A1Guaranteed long-term stabilityReduce the adsorption timeLight-sensitive devicesConductive materialMetal oxide nanoparticlesDesorption

Disclosed is a method for adsorbing a dye for a dye-sensitized solar cell. The method includes: coating a paste including metal oxide nanoparticles on the upper surface of a titanium oxide thin film and calcining the coated paste to form a porous film; adding an additive to a sensitizing dye solution to promote the adsorption of the dye; and dipping the porous film in the sensitizing dye solution to adsorb the sensitizing dye onto the surface of the porous film. The sensitizing dye solution is a dispersion of the sensitizing dye in an organic solvent. Also disclosed are a working electrode prepared using the sensitizing dye solution and a dye-sensitized solar cell including the working electrode. The addition of the additive shortens the time of dye adsorption. Despite the shortened adsorption time, the dye does not undergo desorption in the long term as well as in the short term, ensuring long-term stability of the solar cell.

Owner:KOREA INST OF SCI & TECH

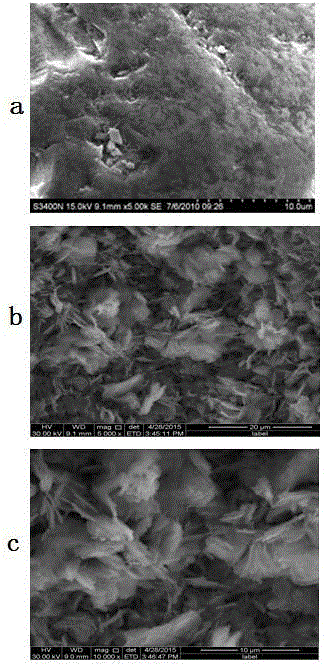

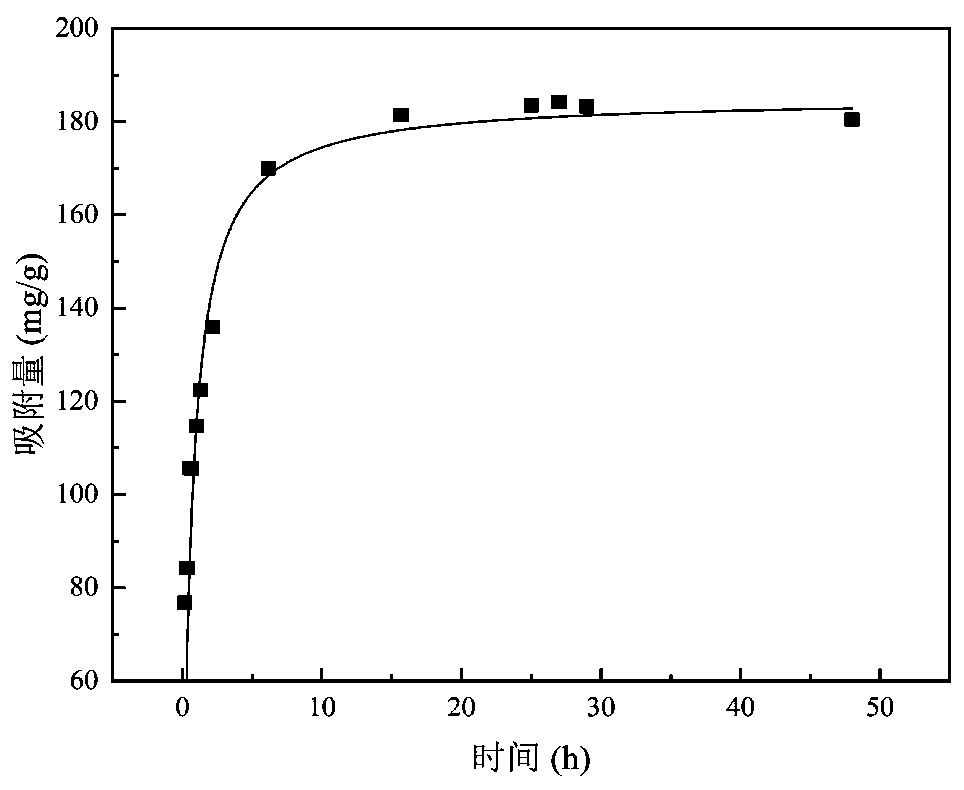

Preparation method and application of sepiolite composite adsorbent loaded with nano zinc sulfide

InactiveCN111408339AExtensive sources of raw materialsModification process is simpleOther chemical processesWater contaminantsPre treatmentCadmium ion

The invention relates to a preparation method and application of a sepiolite composite adsorbent loaded with nano zinc sulfide, and belongs to the technical field of environmental protection. The preparation method comprises acid heat treatment of purified sepiolite and zinc sulfide modification of sepiolite subjected to acid heat treatment, i.e., sepiolite is pretreated through acid heat modification, and then nanoscale zinc sulfide is loaded through coprecipitation, so that the efficient heavy metal cadmium composite adsorbent is prepared. The adsorbent obtained by the invention combines theadvantages of high adsorption capacity of nano zinc sulfide and rich pore structure of sepiolite, and cadmium ions in a water body are efficiently removed mainly by generating a solid solution ZnxCd1-xS (x (1). The preparation method disclosed by the invention is simple, low in production cost, high in removal rate of cadmium in wastewater and low in desorption rate, can be used as an adsorbent or a passivator for heavy metal cadmium in water and soil, and has a good application prospect.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI +1

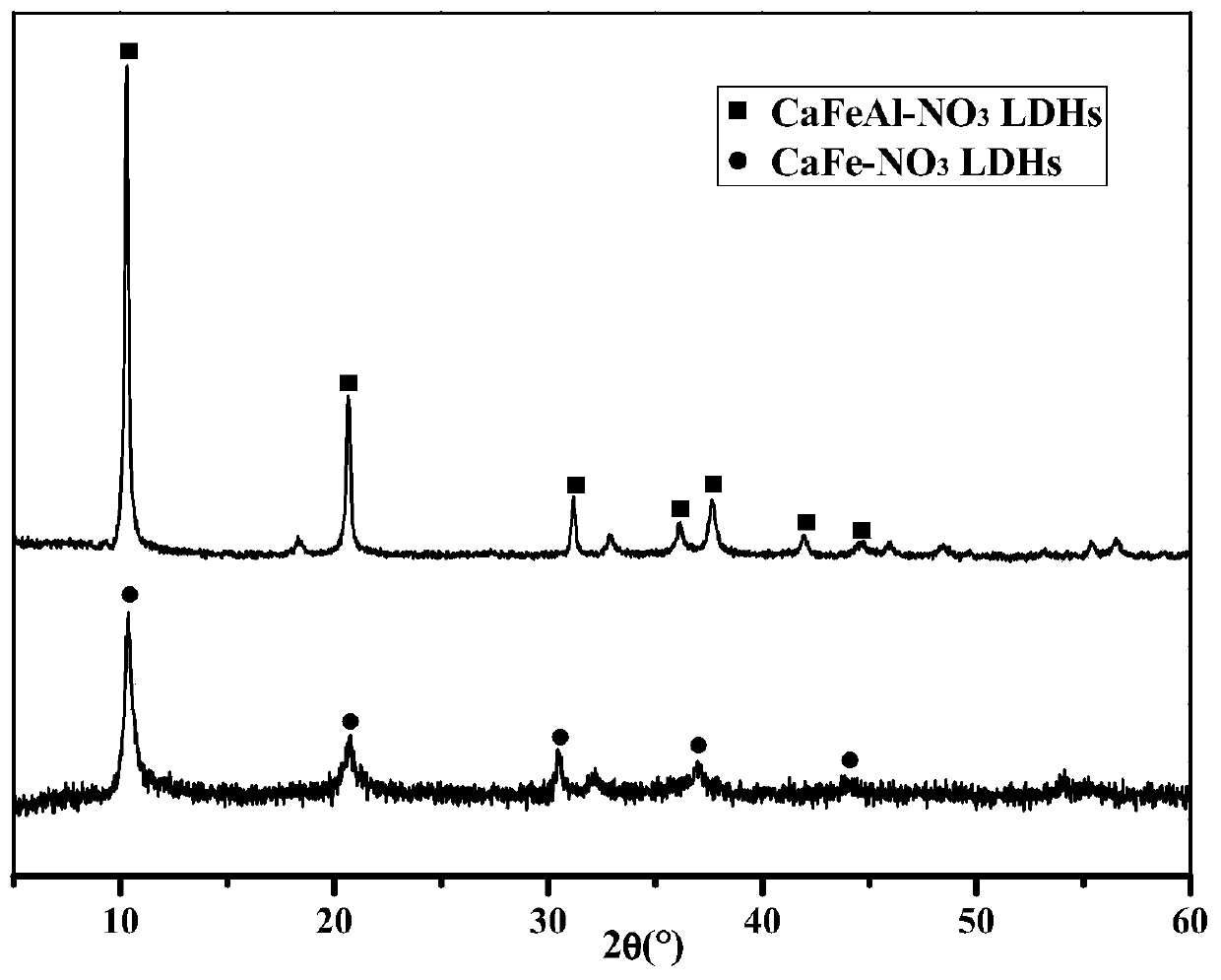

Chlorine ion curing agent for reinforced concrete and preparation method and applications thereof

The invention belongs to the technical field of chlorine ion curing agents, and especially relates to a chlorine ion curing agent for reinforced concrete and a preparation method and applications thereof. The curing agent is metal dihydroxide with a layered structure, has a micro-nano level granular shape, and is prepared by compounding 50 to 80 parts by weight of CaFe-NO3LDHs and 20 to 50 parts by weight of CaFeAl-NO3LDHs. The prepared chlorine ion curing agent does not damage a cement based material, and can stably and efficiently adsorb chlorine ions in a simulated concrete hole solution. In a cement paste sample, which has been soaked in a sodium chloride solution (3.5%), the corrosive performance of chlorine ions is obviously reduced, the effect is excellent, and the provided chlorineion curing agent is efficient and stable.

Owner:UNIV OF JINAN

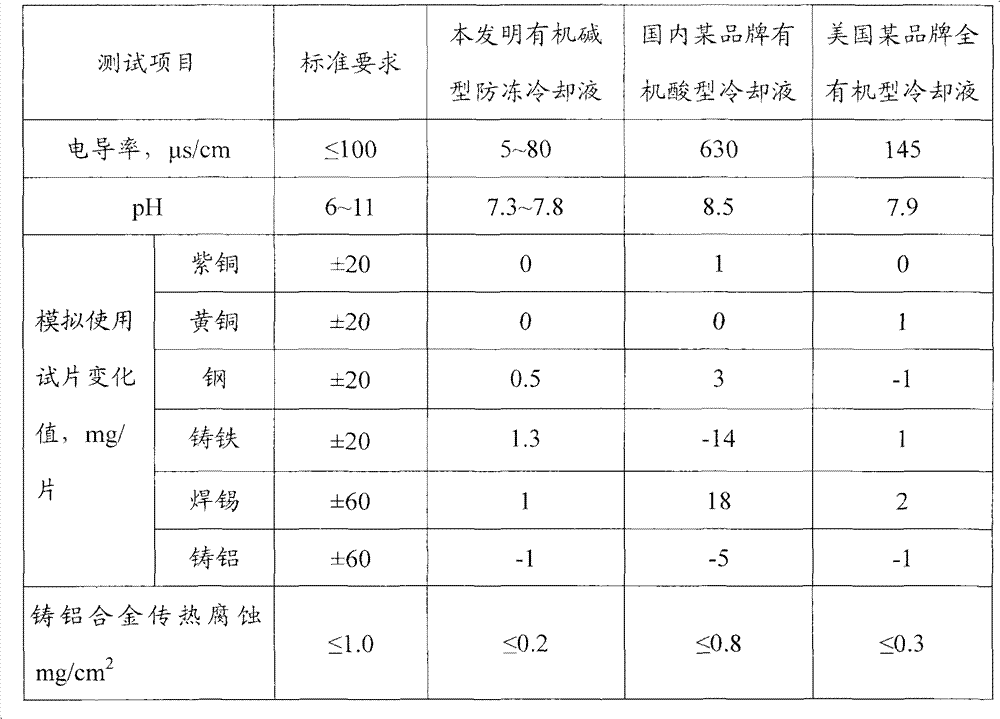

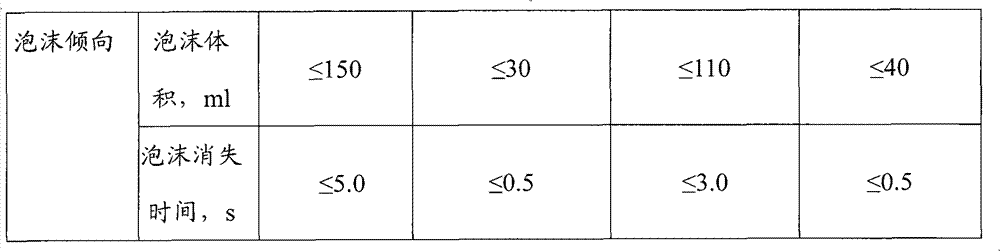

Low-conductivity super-long-acting organic base type anti-freezing cooling liquid

InactiveCN102174313BMeet insulation safety requirementsReduce corrosionHeat-exchange elementsOrganic baseCarboxylic acid

The invention provides low-conductivity super-long-acting organic base type anti-freezing cooling liquid, which comprises the following components in percentage by weight: 15 to 96 percent of anti-freezing agent, 0.05 to 1.5 percent of natural alkaloid, 0.5 to 2.5 percent of hetero-cycloalkane, 0.01 to 0.3 percent of azole component, and the balance of deionized water. In invention, since the natural alkaloid is matched with nonionic organic compounds, the prepared anti-freezing cooling liquid has the characteristics of low freezing point, high boiling point, no scale formation, corrosion protection, high heat efficiency and the like; in addition, the prepared anti-freezing cooling liquid also has ultra-low conductivity which can reach 5 mus / cm and is a few hundredths of the conductivity of a common water cooling medium because the anti-freezing cooling liquid does not contain the components of inorganic salts, organic carboxylic acid and the like. The anti-freezing cooling liquid with ultra-low conductivity can effectively slow up the corrosion on metal parts of a cooling system, and meet the requirement of special conditions such as the cooling of a wind generator set and the like on the insulation safety of the anti-freezing cooling liquid. The anti-freezing cooling liquid realizes environmental protection and ultra-long-acting service, and is particularly suitable for special equipment such as a wind generator set, an imperial sedan engine and the like.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

EVAP system with valve to improve canister purging

InactiveUS20170009673A1Reduced steam emissionsEmission reductionElectrical controlNon-fuel substance addition to fuelEngineeringFuel vapor

Systems and methods are provided for an evaporative emissions control system. In one example, a system for an engine may comprise a fuel vapor canister, a mixing valve positioned in a fresh air line upstream of the vapor canister, and an actuator physically coupled to the mixing valve for adjusting a position of the mixing valve to increase turbulence in air entering the vapor canister. The position of the mixing valve may be adjusted to increase an amount of turbulence in air entering the fuel vapor canister.

Owner:FORD GLOBAL TECH LLC

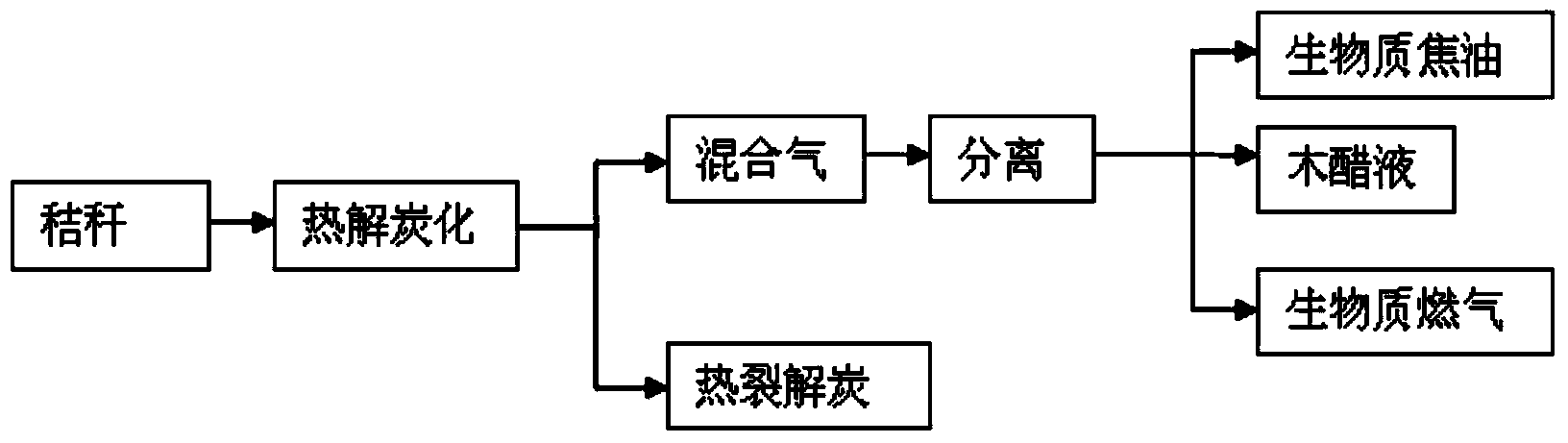

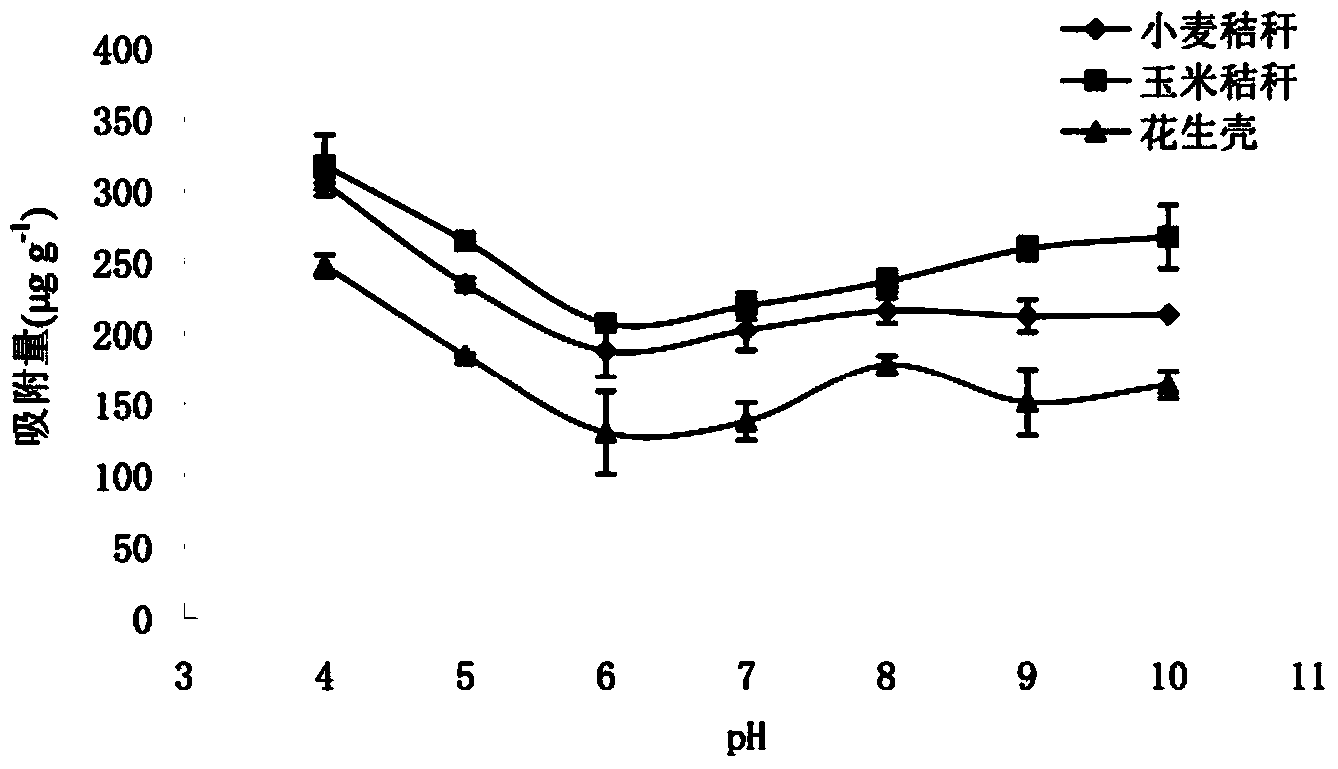

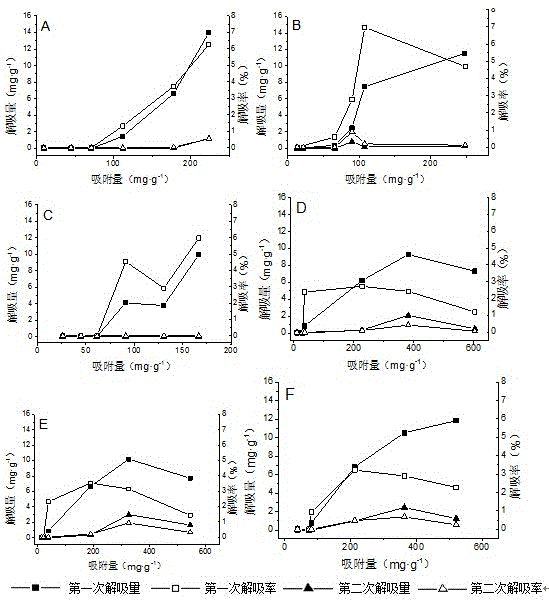

Thermal cracking carbon for removing polycyclic aromatic hydrocarbon in water as well as preparation method and application thereof

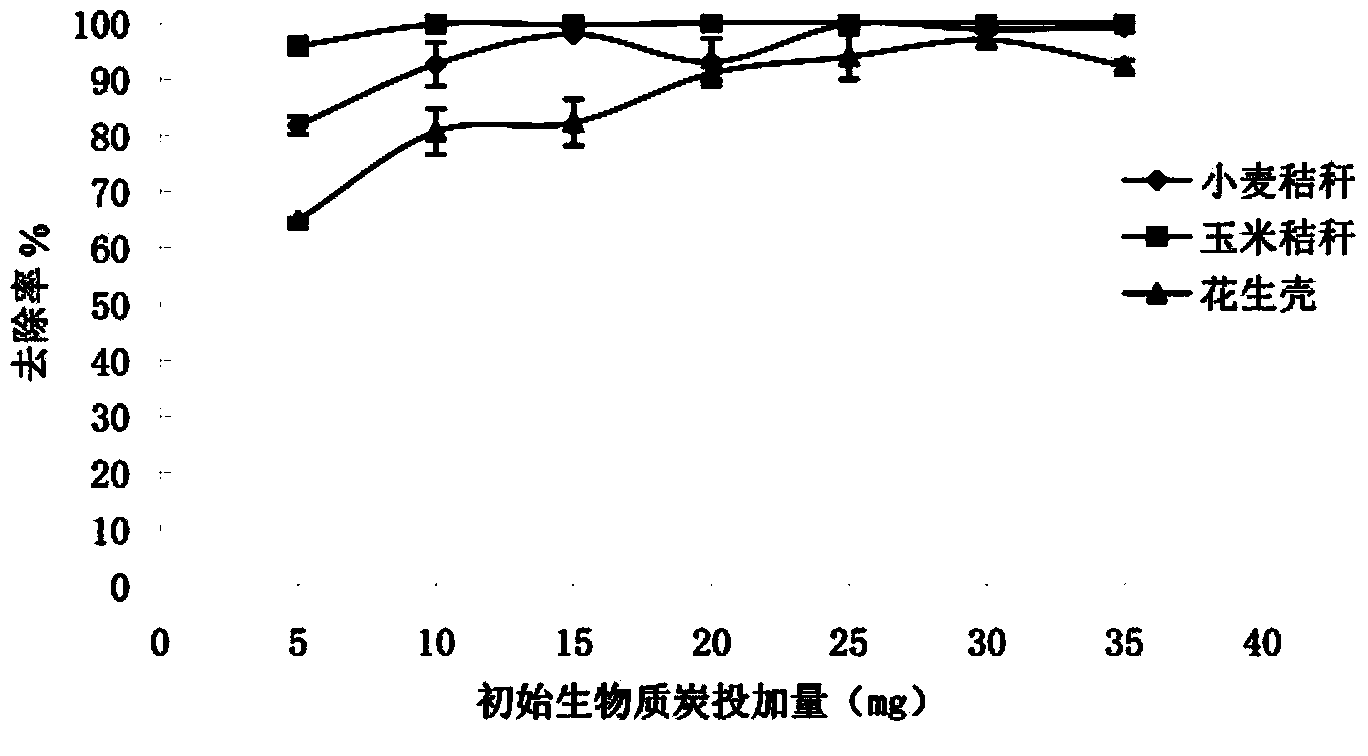

InactiveCN103464103ASolve the problem of inappropriate useAvoid security issuesOther chemical processesWater contaminantsPolycyclic aromatic hydrocarbonDesorption

The invention belongs to the technical field of water environment safety and resource reuse, and relates to thermal cracking carbon for removing polycyclic aromatic hydrocarbon in water as well as a preparation method and an application thereof. The thermal cracking carbon is prepared by the following steps: airing one or more agricultural wastes selected from maize straws, wheat straws or peanut shells; and then carbonizing under an anaerobic condition at 350-500 DEG C. The thermal cracking carbon can be applied to removing polycyclic aromatic hydrocarbon in water. The invention provides a novel adsorbing material, and the thermal cracking carbon is prepared from the raw materials of maize straws, wheat straws or peanut shells which are taken as the thermal cracking carbon, so that not only is the problem that the straws are unreasonably utilized solved, are the agricultural wastes effectively utilized and is the environment purified, but also polycyclic aromatic hydrocarbon is effectively adsorbed, particularly pyrene, and the concentration of polycyclic aromatic hydrocarbon in an organic polluted water body is reduced. The thermal cracking carbon is low in desorption rate, persistent and stable, and the water safety problem is solved, thereby realizing two purposes.

Owner:NANJING AGRICULTURAL UNIVERSITY

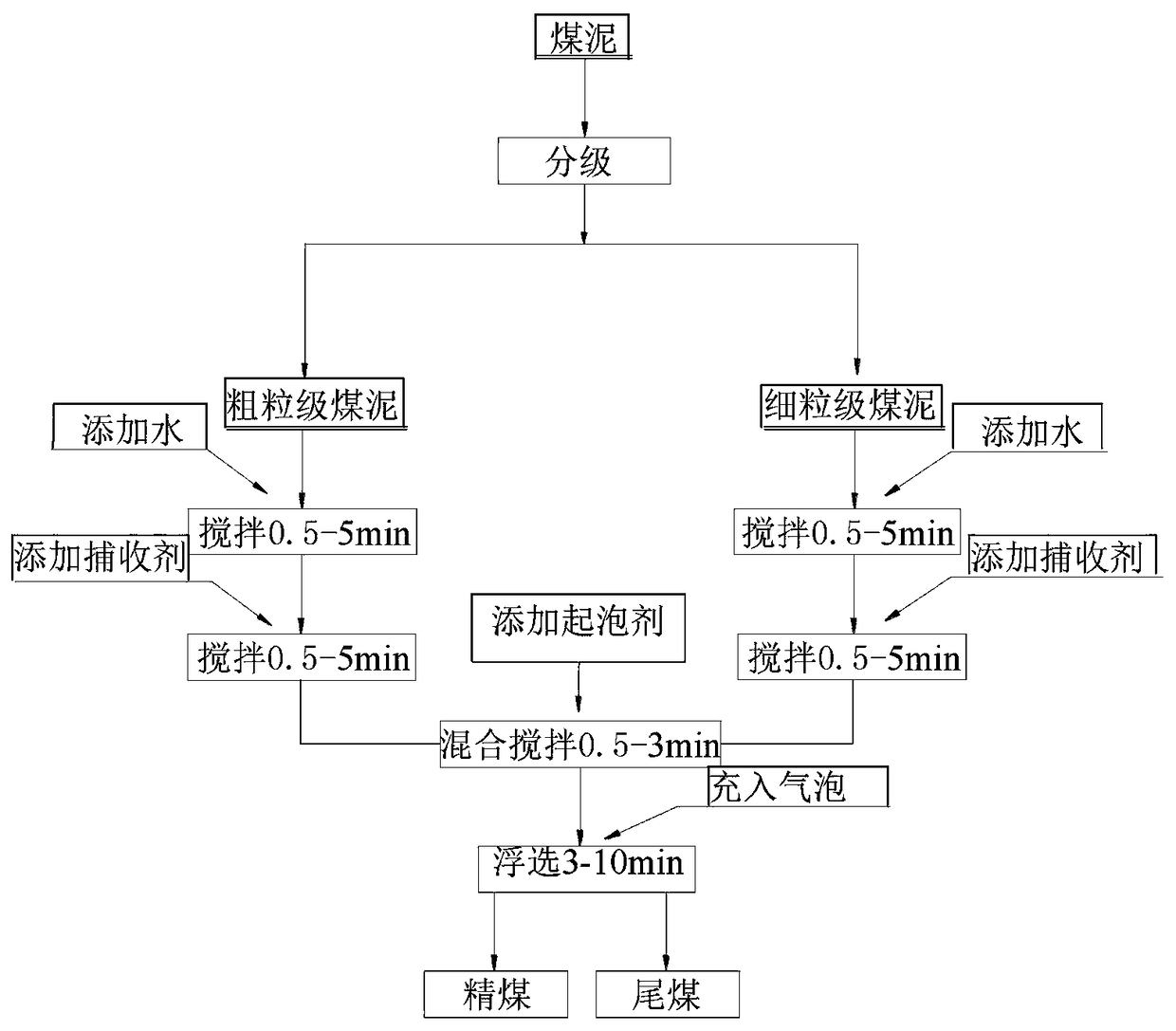

Wide-particle-grade coal slime flotation method

The invention discloses a wide-particle-grade coal slime flotation method. The method comprises the following steps that wide-particle-grade coal slime is divided into a coarse particle grade and a fine particle grade, then water is correspondingly added into the coarse particle grade coal slime and the fine coal slime for stirring so as to prepare ore pulp, collecting agents are correspondingly added into the two kinds of ore pulp for stirring, then the two kinds of ore pulp are transferred into a flotation tank, a foaming agent is added, mixing and stirring are carried out, bubbles are fed,and bubble scraping is carried out as to obtain flotation clean coal and tail coal. According to the method, particle-grade pulp preparation is achieved, and a mixing air inflation process is used, sothat the requirements of coal slime pulp mixing performance of different particle grades are met, the dosage of agents is saved, then covering of high-ash fine mud on the surface of the coarse granular coal can be effectively reduced, the quality of the clean coal is improved, the excessive adhesion of the fine-particle-grade coal slime to the collecting agents is reduced, meanwhile, the desorption rate of the coarse coal slime can be reduced, and the recovery rate of the coarse coal slime can be improved; and the particle-grade pulp preparation and the air inflation flotation process are used for improving the recovery rate of coarse particles in the raw coal, the effective recovery of the wide-particle-grade coal slime is realized, and the flotation problem of the wide-particle-grade coal slime is solved.

Owner:CHINA UNIV OF MINING & TECH

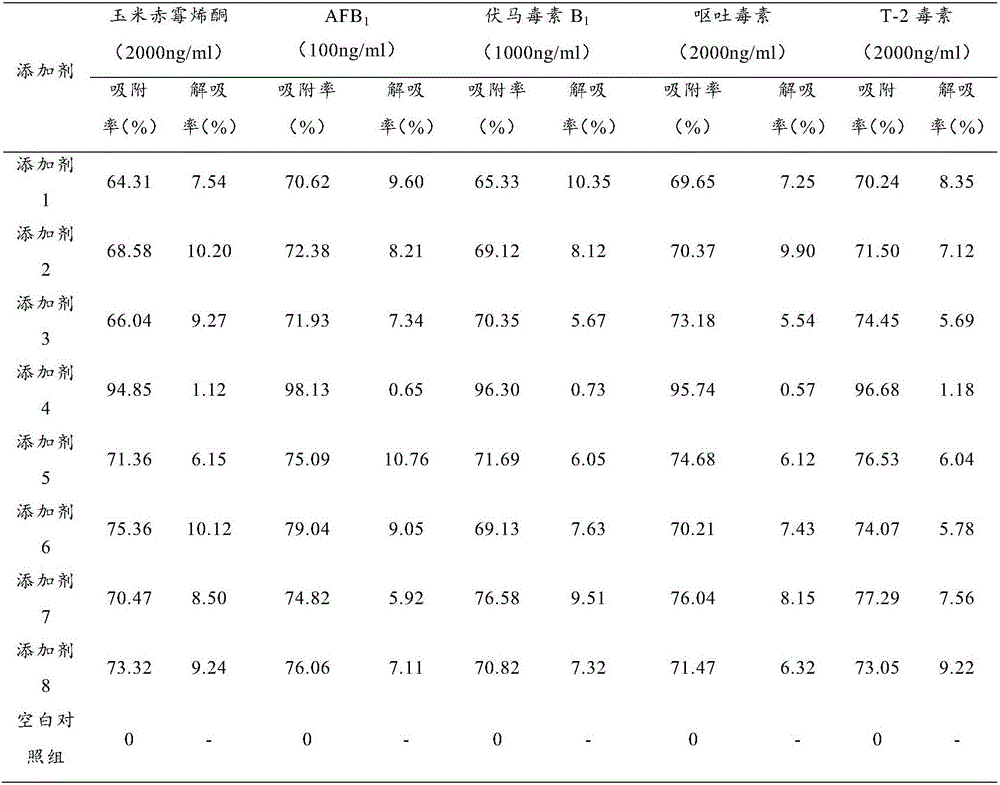

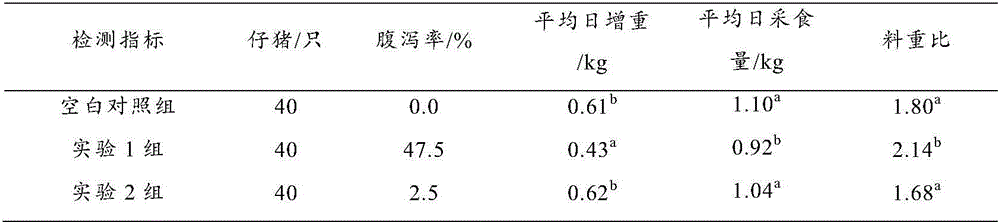

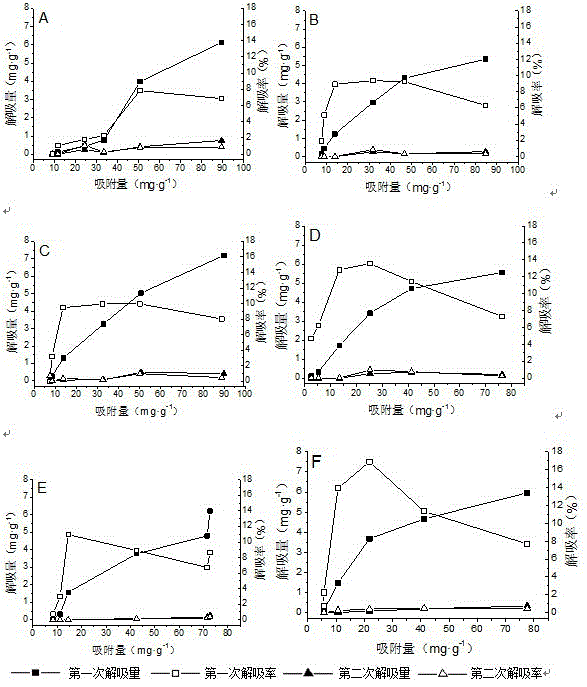

Mycotoxin resistant feed additive for pigs and preparation method and application thereof

InactiveCN106417953AHigh adsorption rateGood synergyAnimal feeding stuffFood scienceDesorptionLactobacillus rhamnosus

The present invention discloses a mycotoxin resistant feed additive for pigs and a preparation method and an application thereof. The present invention firstly discloses the mycotoxin resistant feed additive for the pigs. The feed additive comprises lactobacillus rhamnosus, calcined shells and cornstalk charcoal. The preparation method further increases fructus gardeniae and moutan barks on the basis of the mycotoxin resistant feed additive for the pigs, and can significantly improve the removal rate of the mycotoxin, so that the adsorption rates of zearalenone, aflatoxin B1, vomitoxin, etc. can all reach 94% or more, the desorption rates of the toxins are significantly reduced, and the toxin removing is more complete. The raw materials of the lactobacillus rhamnosus, calcined shells, cornstalk charcoal, fructus gardeniae and moutan barks are tested to have obvious synergic effects. The mycotoxin resistant feed additive for the pigs can be used for detoxification of cereals or compound feeds, etc. contaminated by the mycotoxin, prevents the toxic effects of the mycotoxin on the pigs and improves the feed return rate.

Owner:山东众客食品有限公司

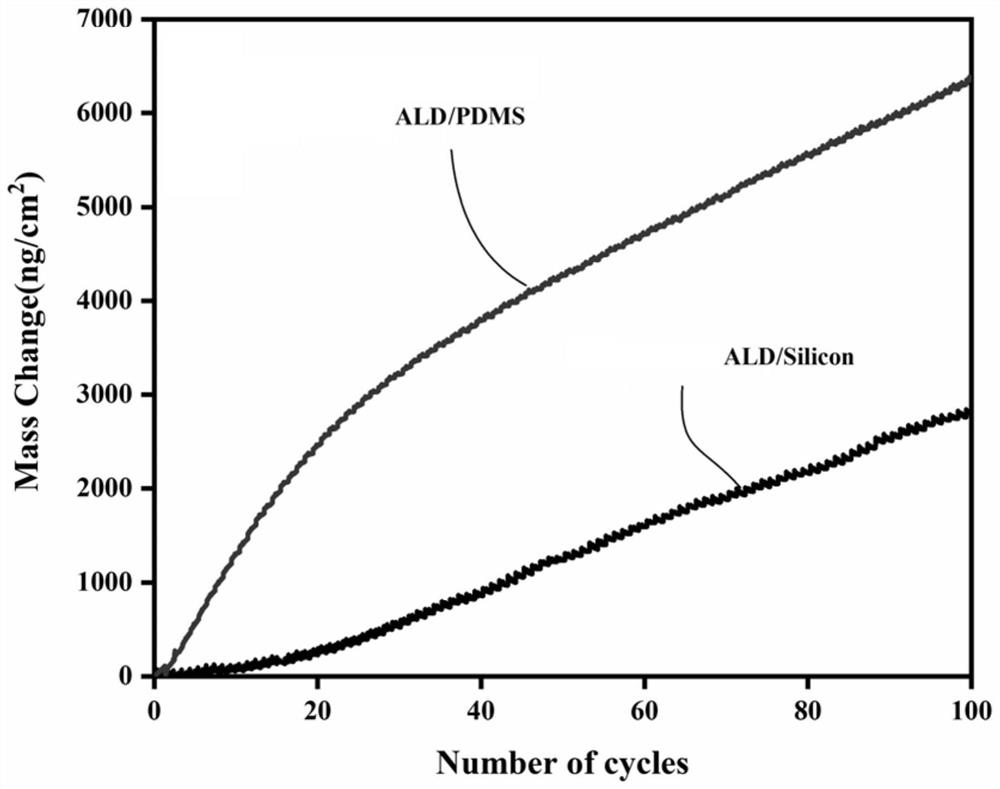

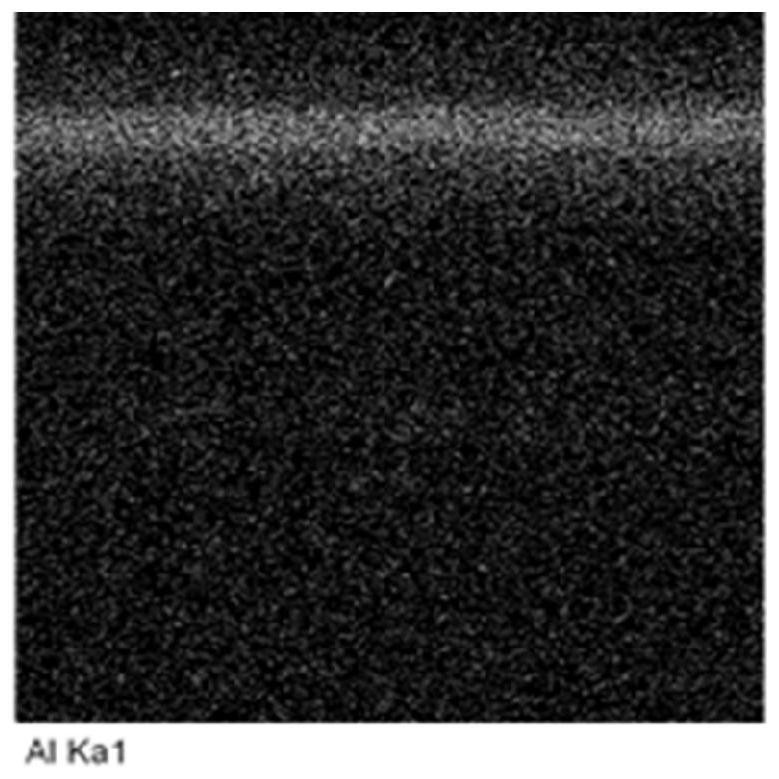

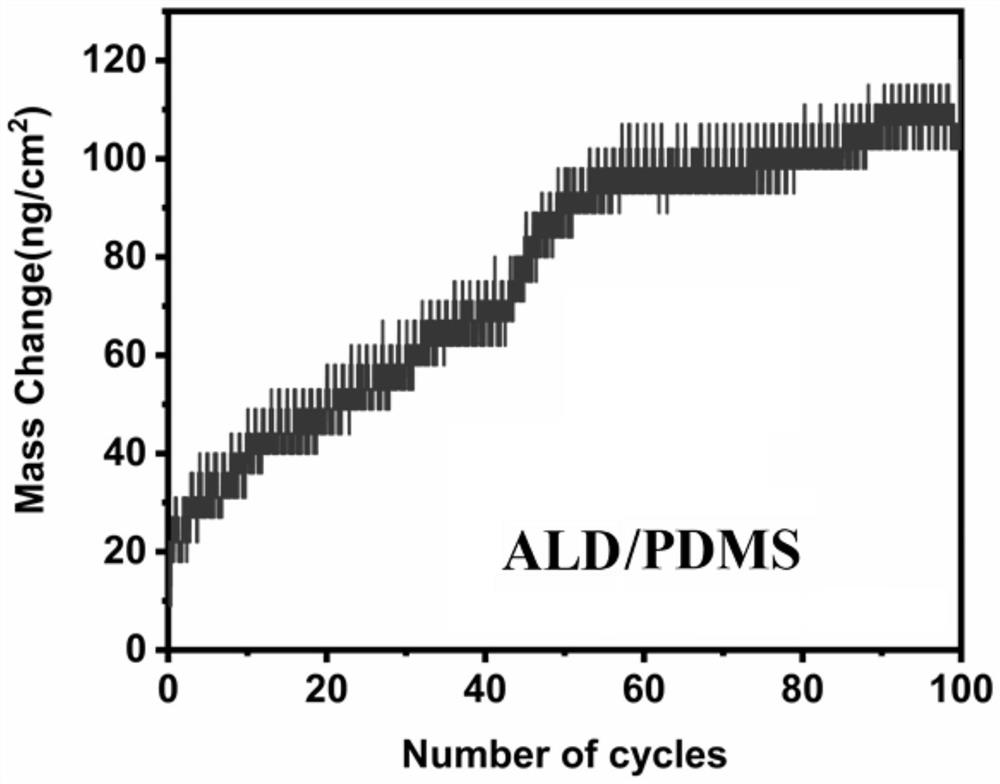

Method for modifying organic polymer material and modified organic polymer material

PendingCN113818010ANo damageWill not cause self-degeneration and decompositionChemical vapor deposition coatingPolymer scienceNitrogen gas

The invention relates to a method for modifying organic polymer material and a modified organic polymer material. The method for modifying organic polymer material comprises the following steps: (1) placing the organic polymer material in an atomic layer deposition reaction chamber; (2) introducing a carrier gas into a precursor 1, sealing an atomic layer deposition reaction chamber for 180-600 seconds for the first time, and introducing an inert gas for purging and cleaning; and (3) introducing into a precursor 2 again, and sealing the atomic layer deposition reaction chamber for 180-600 seconds for the second time; wherein the precursor 2 is selected from ammonia plasma or mixed plasma of nitrogen and hydrogen. According to the invention, an ALD technology is utilized, a nitrogen-containing precursor is taken as a main raw material, a nitride is filled into the organic polymer material at proper filling depth and filling density, a film is formed on the surface of the organic polymer material, and the modified organic polymer material with better chemical and mechanical properties is obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

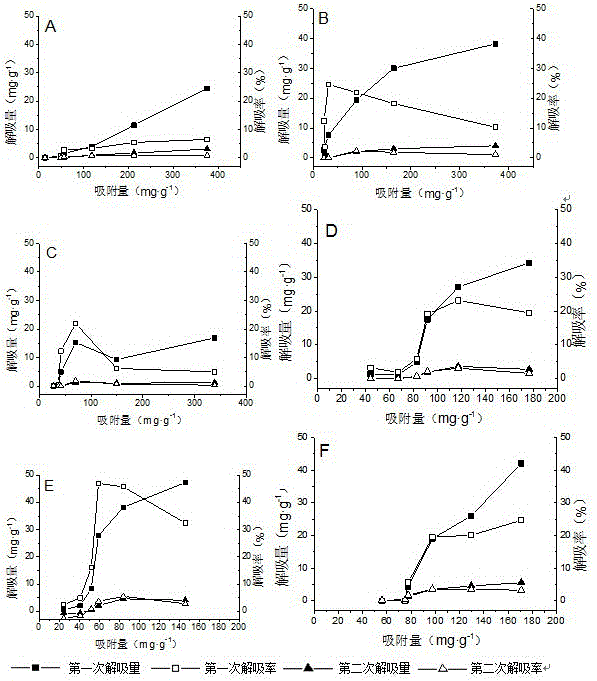

Method for regulating heavy metal desorption of compost extract liquid by adopting carbon nanomaterial

InactiveCN106116722AHigh desorption rateLow desorption rateBio-organic fraction processingOrganic fertiliser preparationConcentration ratioPhysical chemistry

The invention discloses a method for regulating heavy metal desorption of a compost extract liquid by adopting a carbon nanomaterial. The method comprises steps as follows: a mixed solution containing three kinds of heavy metal ions including Cu<2+>, Pb<2+> and Cd<2+> is prepared, and a concentration ratio of the three kinds of heavy metal ions is 6:4:1; the prepared heavy metal mixed solution and the compost extract liquid in a mass ratio being 1:2 are mixed; 10 mg of the carbon nanomaterial is weighed and put into a conical flask, 20 ml of the heavy metal mixed solution or 20 ml of the pure compost extract liquid is added to the conical flask, and a mixture is oscillated for 6 h, is filtered and then is measured. The invention further discloses an application of the method for regulating the heavy metal desorption of the compost extract liquid by adopting the carbon nanomaterial in the aspect of increase of desorption rate of the heavy metal including Cu<2+>, Cd<2+> and Pb<2+>. The desorption rate of the heavy metal refers to desorption of Cd, Cu and Pb by the aid of graphene, graphene oxide and multi-walled carbon nanotubes.

Owner:TIANJIN NORMAL UNIVERSITY

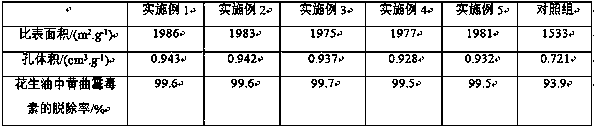

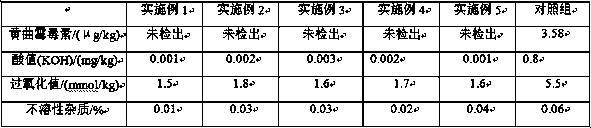

Preparation method of adsorbent for removing aflatoxin in peanut oil

InactiveCN108905982AImprove adsorption capacityImprove adsorption stabilityOther chemical processesFatty-oils/fats refiningHazardous substanceSorbent

The invention belongs to the technical field of quality safety of cereal oil and in particular relates to a preparation method of an adsorbent for removing aflatoxin in peanut oil. The preparation method of the adsorbent comprises the following steps: firstly, taking longan branches, lychee branches and bagasse as raw materials; after mixing and crushing, adding rice shell powder and alkaline ionic liquid to prepare activated carbon; then carrying out amination treatment on the activated carbon; finally, compounding he activated carbon subjected to the amination treatment and chitosan to prepare the compound adsorbent. The adsorbent prepared by the method provided by the invention has the advantages of rapid adsorption speed and strong adsorption performance and can be used for effectivelyremoving harmful substances including the aflatoxin in the peanut oil and the like; the safety performance of the peanut oil is greatly improved; meanwhile, nutrient substances in the peanut oil canbe kept relatively well.

Owner:广西南宁荣威德新能源科技有限公司

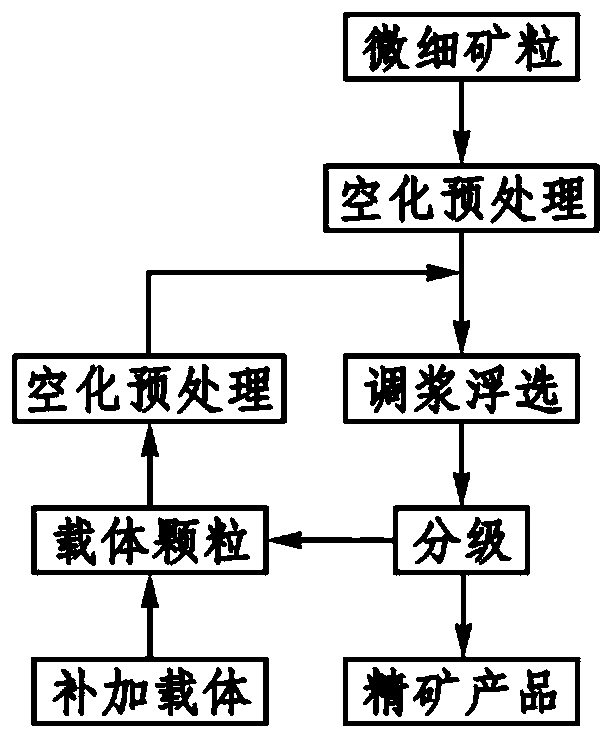

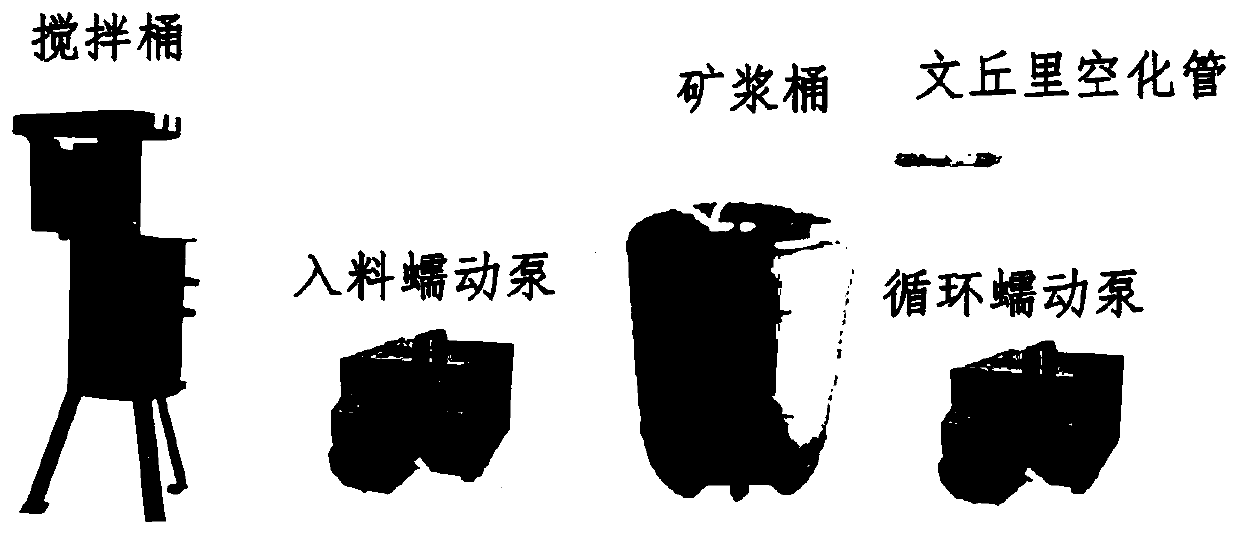

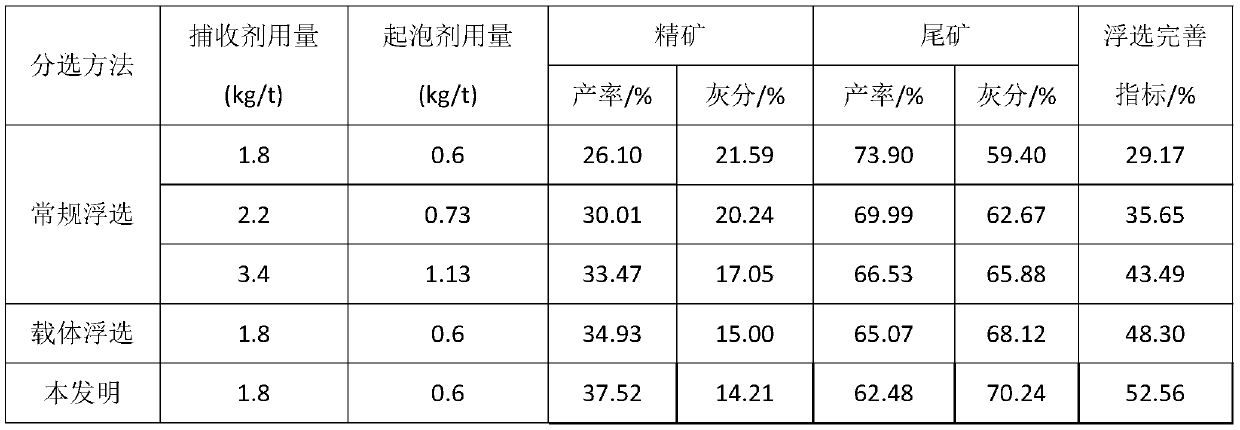

Fine mineral separation method combining cavitation pretreatment and carrier flotation

The invention relates to a fine mineral separation method combining cavitation pretreatment and carrier flotation, which is suitable for coal separation. The method includes preparing pulp by utilizing fine minerals, adding a collector, then adjusting the pulp, and circulating the adjusted pulp in a venturi cavitation tube to achieve cavitation; preparing carrier particle pulp, adding a collector,and circulating the adjusted carrier particle pulp in a venturi cavitation tube to achieve cavitation; stirring the adjusted fine mineral pulp after cavitation and the adjusted carrier particle pulpafter cavitation according to a ratio, conveying the mixture to a flotation machine, performing flotation to finally obtain a foam product and a tailing product, and recovering carrier particles. Thesteps are simple, the effect is good, the collision probability of fine particles and flotation bubbles is increased, and the selectivity of flotation is improved. The carrier particles are cleaned bycavitation pretreatment and recycled, thus reducing the loss of the carrier particles; cavitated nano-bubbles on the surfaces of the carrier particles can also promote the adhesion of the carrier particles and the flotation bubbles, thus improving the efficiency of carrier flotation.

Owner:CHINA UNIV OF MINING & TECH

Composite detoxification agent capable of removing zearalenone

The invention discloses a composite detoxification agent capable of removing zearalenone. The composite detoxification agent comprises the following raw materials in parts by weight: 30-45 parts of rectorite, 8-19 parts of zeolite, 10-20 parts of sepiolite, 5-17 parts of rice husk charcoal, 5-13 parts of modified konjac glucomannan, 5-15 parts of sodium humate, 1-3 parts of vitamin E, 2-11 parts of compound bacteria and 5-15 parts of surfactants. The composite detoxification agent, which is provided by the invention, capable of removing the zearalenone has a high zearalenone detoxification rate and a stable effect.

Owner:HUANGSHAN BAIYUE ACTIVATED CLAY

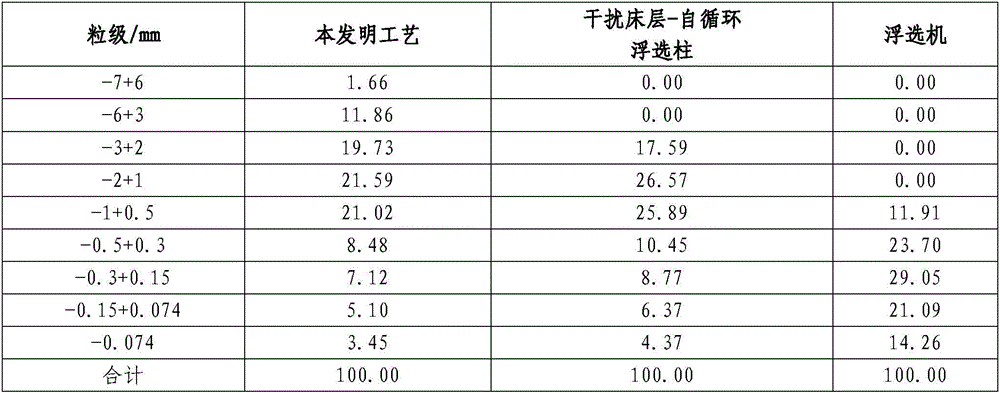

Flotation technology for wide-size coal slime

ActiveCN105709941AReduce the probability of desorptionIncrease the upper limit of sorting granularityFlotationMicro bubbleCoal

The invention discloses a flotation technology for wide-size coal slime. The flotation technology comprises the ore pulp preparation work, the high-pressure jetting work, the bubble removal work and the flotation work in a teetered bed-self-circulation flotation column; the bubble removal technology is added after a self-absorption micro-bubble generator, non-active bubbles are removed through the bubble removal work, the phenomenon that excessive bubbles enter the teetered bed-self-circulation flotation column and form an ultra-thick bubble layer is avoided, the influence of the non-active bubbles on subsequent sorting is eliminated, appropriate common bubbles are generated through a bubble generator of the teetered bed-self-circulation flotation column according to needs, the common bubbles and active micro-bubbles are adjusted for realizing the appropriate proportion by controlling the consumption of bubble forming agents, and therefore the floatation efficiency can be improved to the maximum degree.

Owner:SHANDONG UNIV OF SCI & TECH

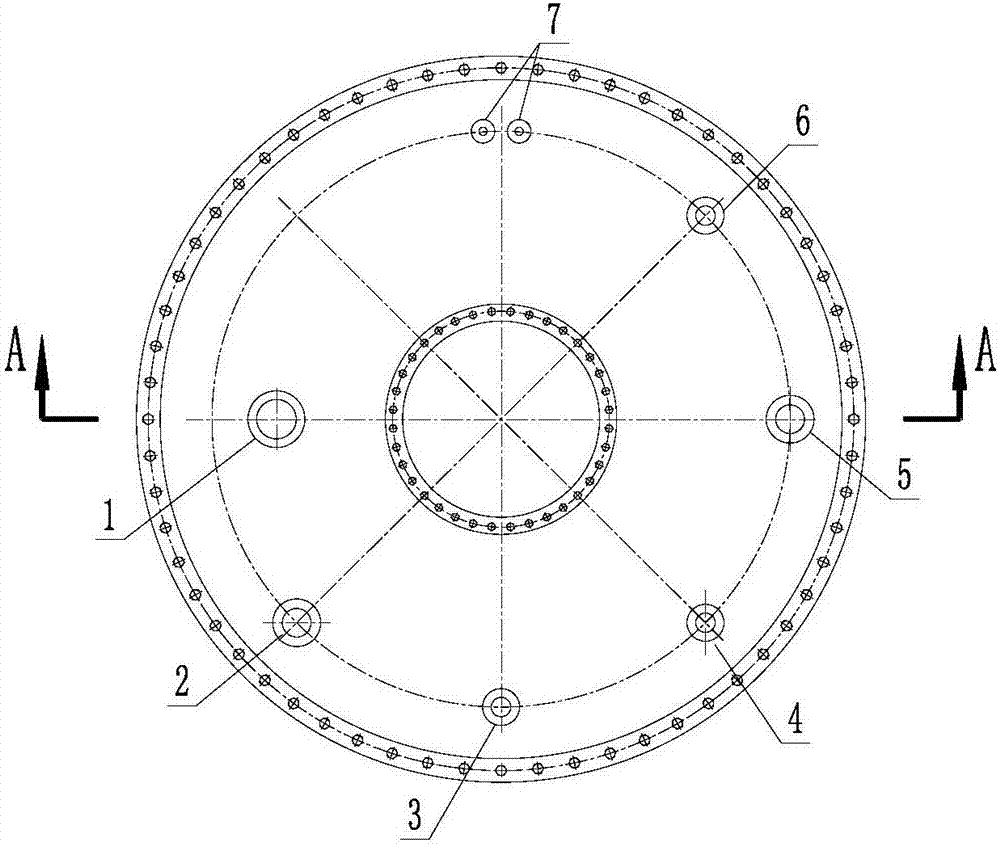

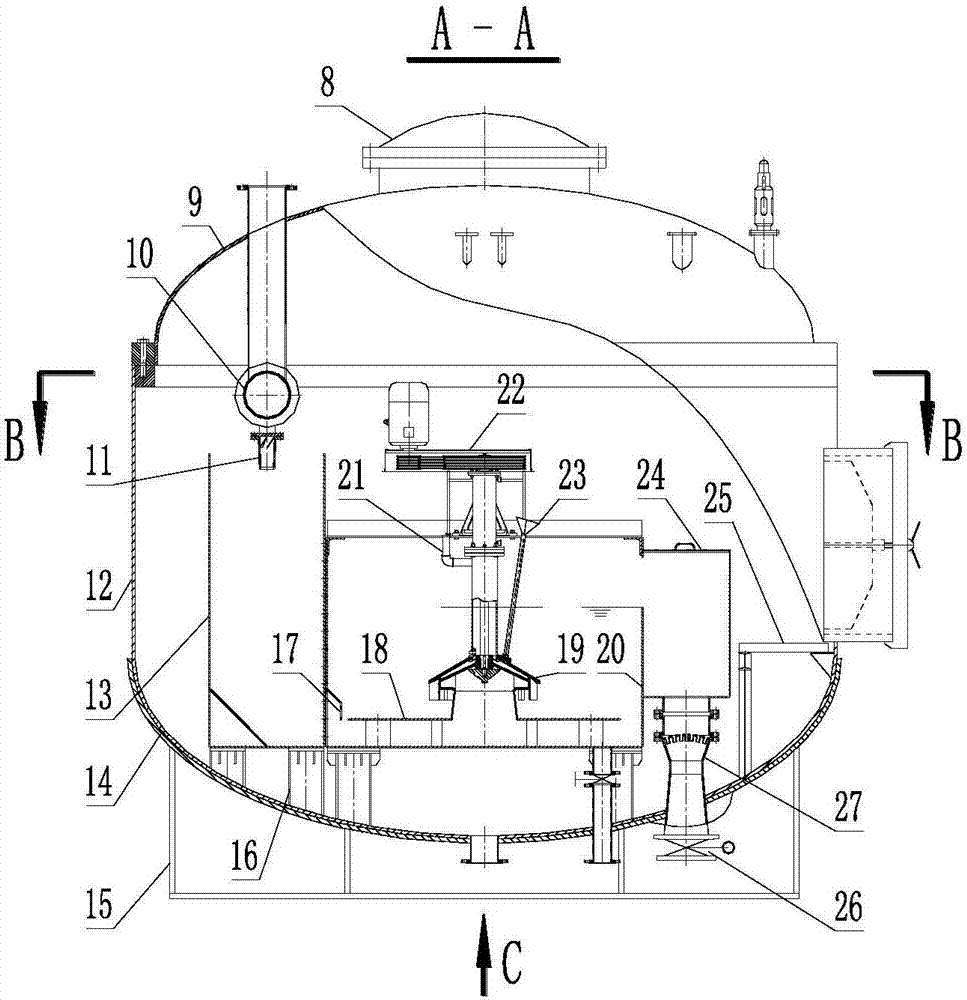

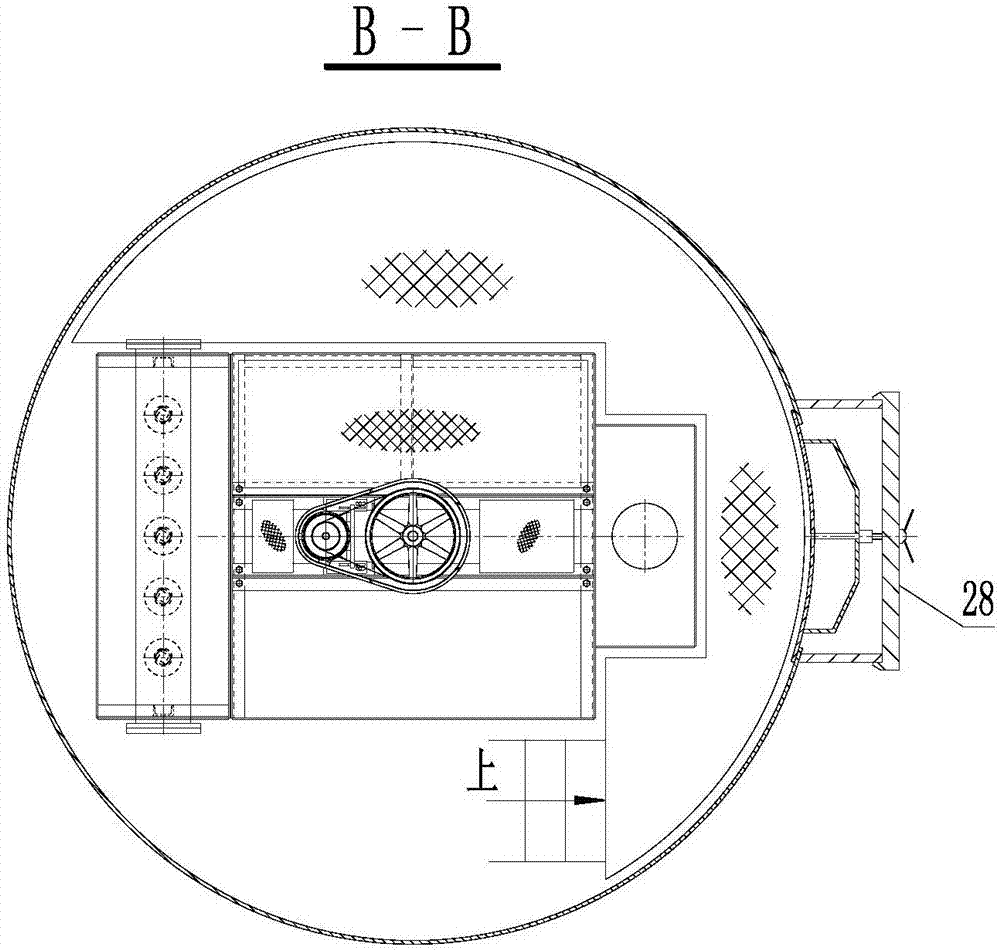

Pressurization gas dissolution type coal slime mixing device

ActiveCN107497591AProminent precipitationImprove the mixing effectSolid separationPulp and paper industryDissolution

The invention relates to a pressurization gas dissolution type coal slime mixing device, and belongs to the technical field of coal slime flotation equipment. The pressurization gas dissolution type coal slime mixing device is used for coal slime flotation pulp mixing treatment. According to the technical scheme, the pressurization gas dissolution type coal slime mixing device comprises a pressurization bin, an ore pulp feeding jetting device, a stirring pulp mixing device and a pressure reduction discharging device; the pressurization bin is of a cylindrical structure, ellipsoid-shaped sealing heads are arranged at the two ends of the pressurization bin, the sealing head at the upper portion is connected with a barrel of the pressurization bin through a detachable flange, the sealing head at the lower portion and the barrel of the pressurization bin are welded, and the ore pulp feeding jetting device, the stirring pulp mixing device and the pressure reduction discharging device are all installed in the pressurization bin. According to the pressurization gas dissolution type coal slime mixing device, the characteristics of aerosol feeding, intense stirring and the like are kept, the gas dissolution time is prolonged, the gas dissolution pressure is improved, the process of microvesicle separation is highlighted, the coal slime mixing effect is strengthened, and adaptability of flotation equipment for inlet flotation ore pulp is strengthened. The pressurization gas dissolution type coal slime mixing device has the beneficial effects that the unit treatment capacity of the flotation equipment can be improved, and agent consumption is reduced; and the pressurization gas dissolution type coal slime mixing device is very suitable for flotation of low-rank coal slime with poor surface hydrophobicity and slime with large particle size.

Owner:TANGSHAN BRANCH COAL SCI ACAD

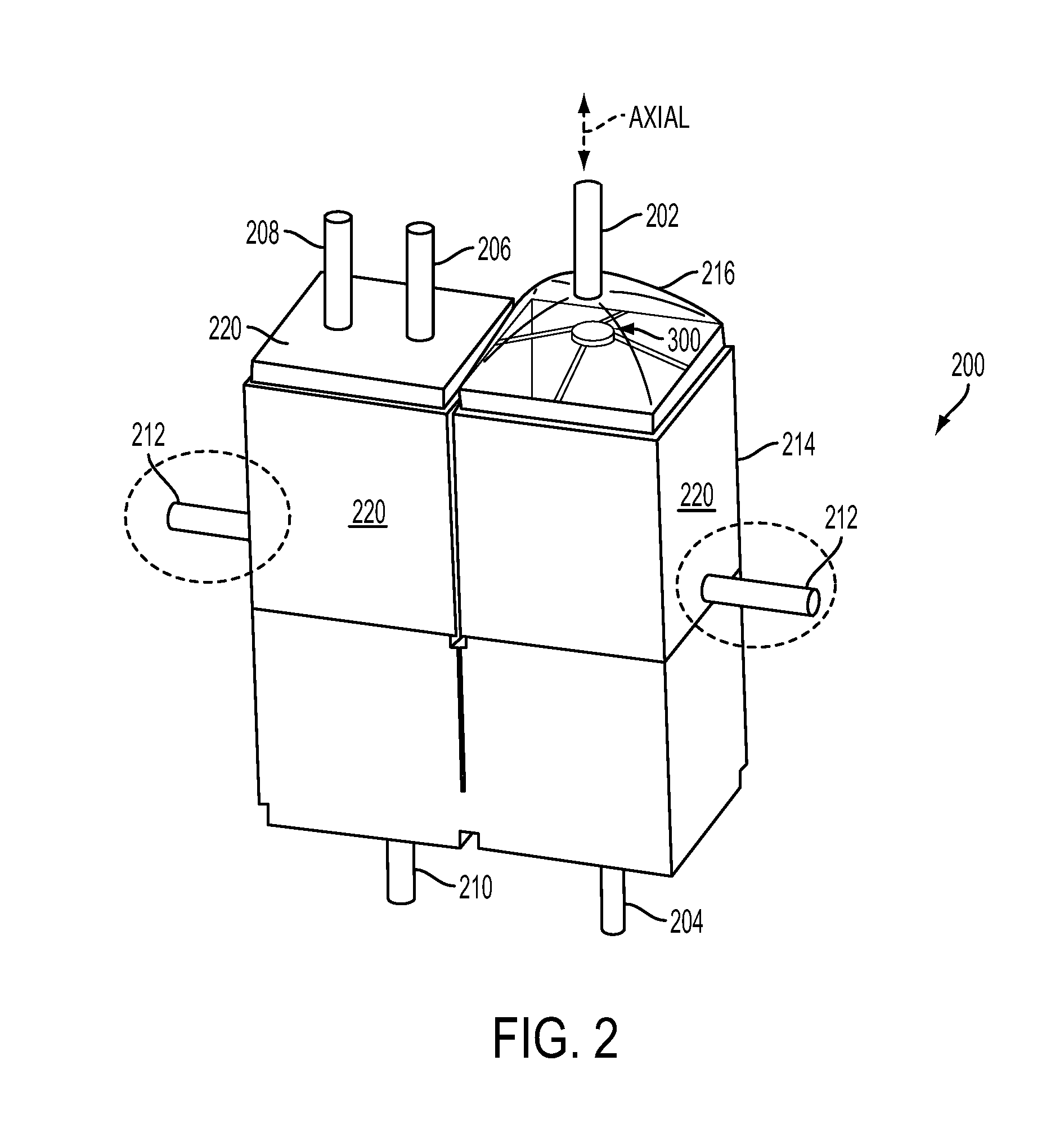

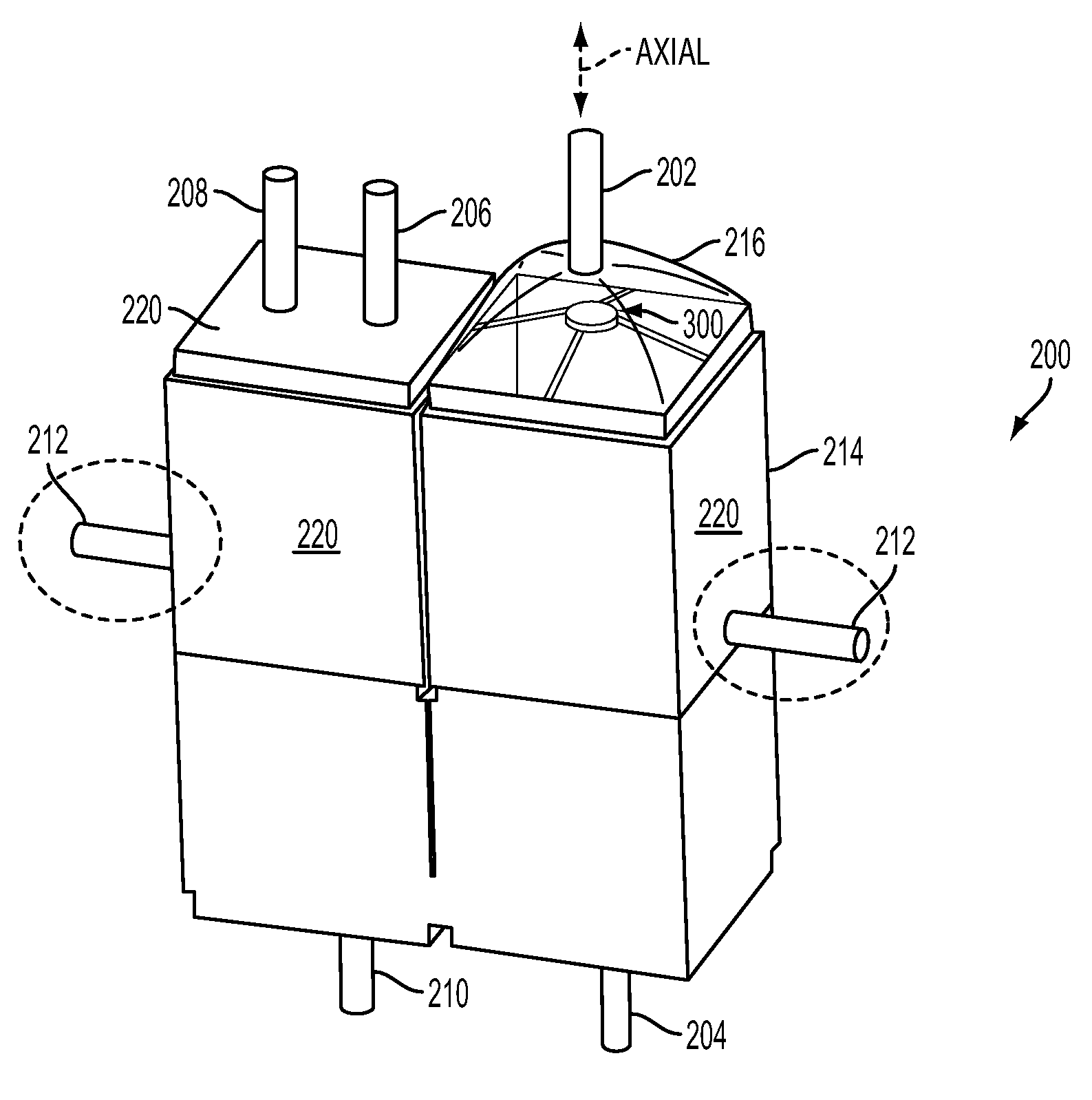

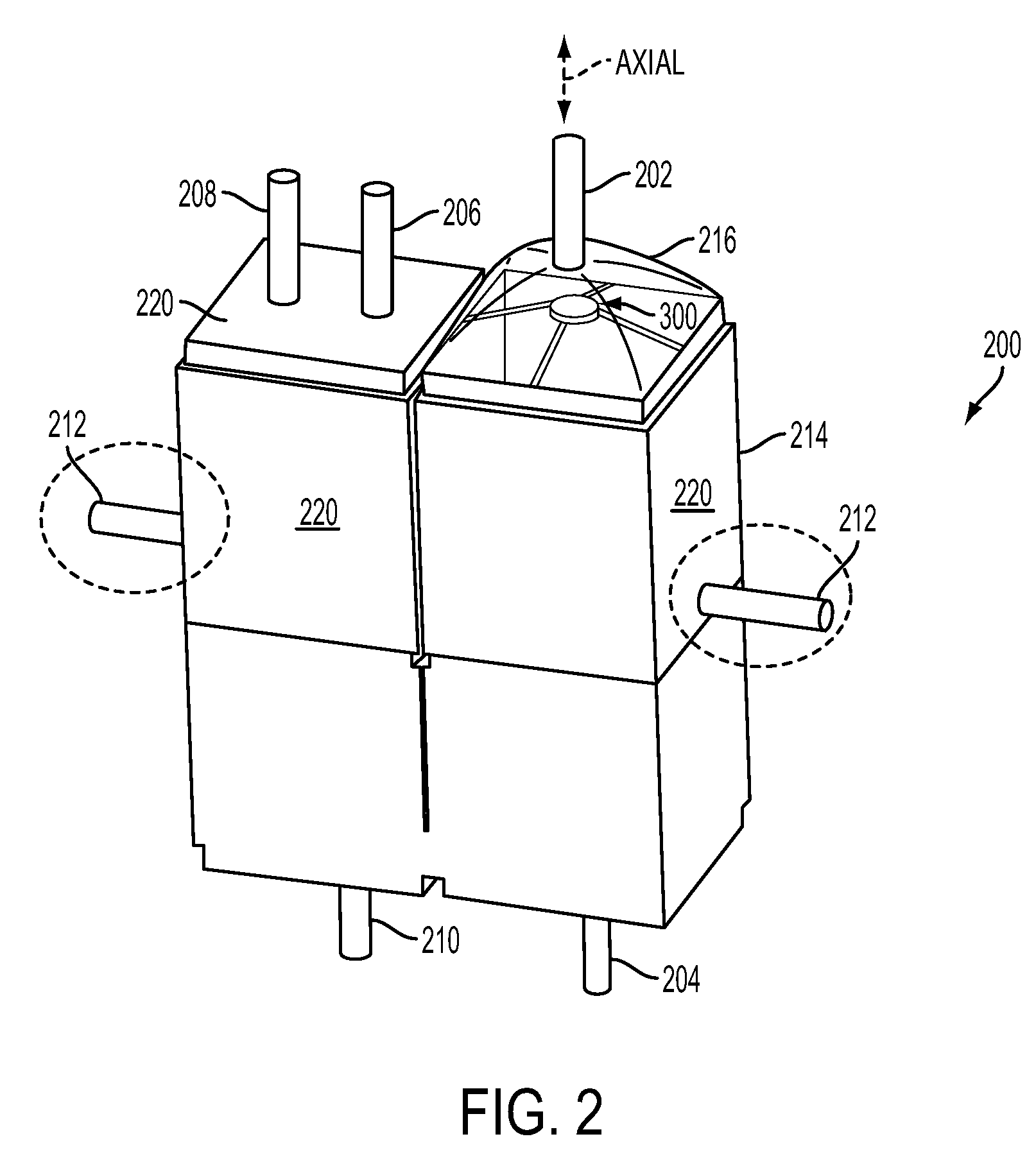

Vapor storage device having a diffuser plate and dome

ActiveUS20150021407A1Reduced steam emissionsEmission reductionNon-fuel substance addition to fuelDispersed particle separationLeading edgeEngineering

A vapor storage device is provided. The vapor storage device includes a diffuser plate positioned on an axis of an inlet port and comprising one or more openings extending through the plate from a leading edge to a trailing edge and a dome coupled to the inlet port of the device and the diffuser plate, where the dome includes side walls spaced away from the diffuser plate.

Owner:FORD GLOBAL TECH LLC

A column separation device and method for mineralization-flotation separation

ActiveCN109759243BImprove recycling effectIncrease the probability of collisionFlotationMineral particlesSlurry

A column separation device and method for mineralization-flotation separation, suitable for use in mineral processing technology. Including mixing barrel, pump, bubble generator, mineralization chamber, turbulence elimination pipe, flotation column and air compressor; after the entering flotation pulp is mixed by pulping equipment, it enters the cyclone mineralization chamber after passing through the bubble generator, and rotates at high speed. The high-intensity turbulent collision between the ore pulp and the bubbles occurs to form mineralized bubbles. The mineralized bubbles pass through the turbulence-eliminating tube to eliminate large eddies and then enter the static separation area of the flotation column to complete the static separation. Baffles prevent the slurry from entering the tailings from a short circuit, and the ore particles that have not completed mineralization and desorption are intensively recovered, the low-ash clean coal is recovered, and the high-ash minerals are discharged from the tailings port. It effectively reduces the flotation shedding probability of low-ash and coarse particles, has large equipment processing capacity, strong adaptability to different coal qualities, low production and operation costs, convenient installation and operation, and overall improves the quantity and quality of clean coal products.

Owner:CHINA UNIV OF MINING & TECH +2

Feed capable of improving body immunity of suckling pigs

InactiveCN108902512AEnhance immune functionAperture well developedAnimal feeding stuffAccessory food factorsMycotoxinLicorice roots

The invention discloses feed capable of improving the body immunity of suckling pigs. The feed is prepared from the following raw materials in parts by weight: 60-80 parts of corn flour, 10-20 parts of peanuts, 15-25 parts of sweet potato powder, 12-18 parts of fish meal, 8-14 parts of dried small shrimp powder, 20-35 parts of fermented bean meal, 25-45 parts of whey powder, 5-9 parts of soybean oil, 8-16 parts of Chinese herbal medicine powder, 1-1.5 parts of a probiotic preparation, 3-7 parts of modified attapulgite and 4-7 parts of nutritional additives, wherein the raw materials of the Chinese herbal medicine powder comprise tuckahoe, haws, dandelion herb, atractylodes rhizome, dried rehmannia roots, radix angelicae sinensis and honey-fried licorice roots; and the raw materials of themodified attapulgite comprise attapulgite, 2,3-epoxy propyl-trimethyl ammonium chloride, a sulfuric acid solution, ethanol and water. The feed disclosed by the invention can reinforce the body immunefunctions of suckling pigs, promote appetite and avoid harm of mycotoxin, thereby reducing mortality and improving the survival rate.

Owner:ANHUI JINMU FEED

Vapor storage device having a diffuser plate and dome

ActiveUS9168829B2Reduced steam emissionsEmission reductionNon-fuel substance addition to fuelDispersed particle separationLeading edgeTrailing edge

A vapor storage device is provided. The vapor storage device includes a diffuser plate positioned on an axis of an inlet port and comprising one or more openings extending through the plate from a leading edge to a trailing edge and a dome coupled to the inlet port of the device and the diffuser plate, where the dome includes side walls spaced away from the diffuser plate.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com