Thiolated bentonite for remedying heavy metal polluted soils and preparation method thereof

A technology for polluting soil and bentonite, applied in chemical instruments and methods, soil conditioning materials, organic fertilizers, etc., can solve the problems of high cost and high usage of 3-mercaptopropyltrimethoxysilane, and achieve low cost and good soil. The effect of passivation repair and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of mercapto bentonite: mix bentonite, ethanol solution of mercapto compound, sodium silicate and water to form a mixed solution, after stirring and reacting, wash, filter and dry to obtain mercapto bentonite; wherein, ethanol of mercapto compound The solution is prepared by dissolving the mercapto compound in ethanol, and the ethanol solution of the mercapto compound is prepared by a volume ratio of 1:19 to 99 between the mercapto compound and ethanol; since the mercapto reagents used in the present invention are few, the preferred mercapto compound and ethanol The volume ratio is 1:99.

[0039] Wherein, the bentonite may be calcium-based bentonite.

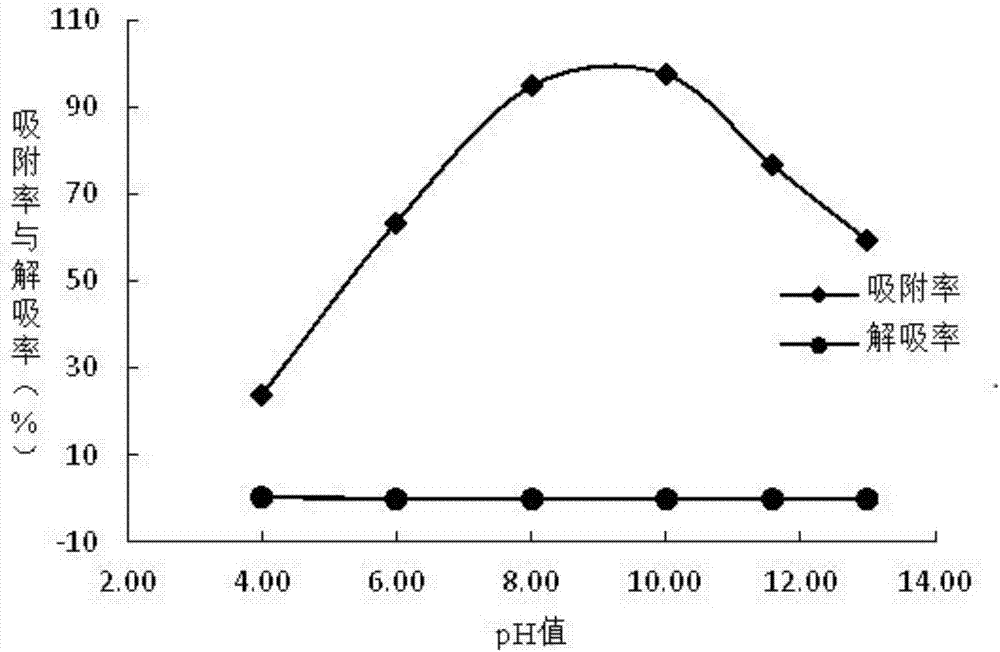

[0040]Since the greater the liquid-solid ratio of the mixed liquid, the worse the modification effect, and the greater the desorption rate, that is, the easier it is to be desorbed. Therefore, preferably, the liquid-solid ratio of the mixed liquid is 15-25mL:1g; A more preferred liquid-solid ratio o...

Embodiment 1

[0047] Example 1 Preparation of mercaptolated bentonite (1#), the mass ratio of bentonite raw soil to 3-mercaptopropyltrimethoxysilane is 1:0.05.

[0048] Weigh 2.00g of bentonite raw soil into a 100mL small beaker, add 10mL of 1% 3-mercaptopropyltrimethoxysilane ethanol solution and 0.12g of sodium silicate powder, add a certain amount of distilled water to make the solid-liquid ratio of the system 1g : 20mL, mix well, adjust the pH of the solution to be 9.50~10.00, stir and react at room temperature for 6h, wash with distilled water until neutral, filter with suction, dry at 40°C, grind and pass through 80 mesh sieve to obtain thiolated bentonite.

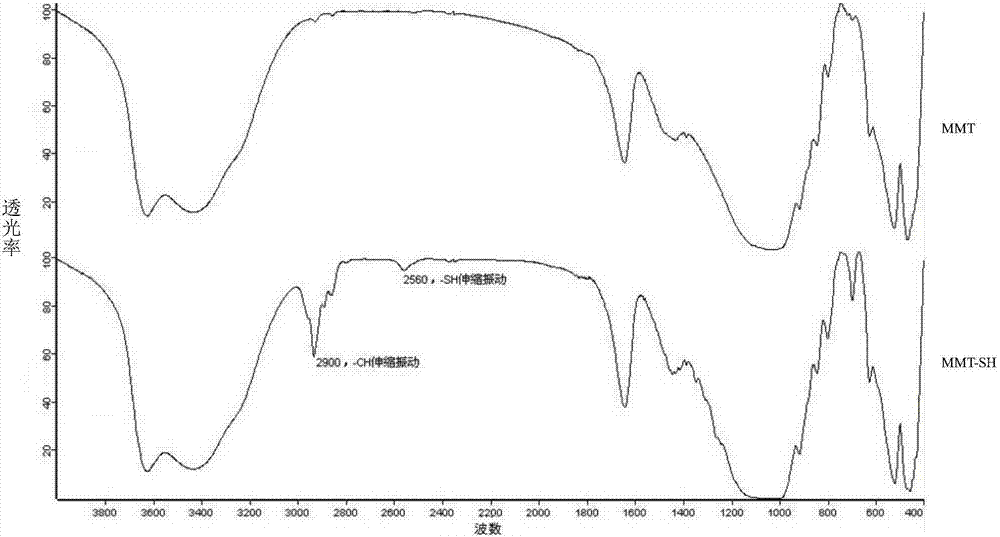

[0049] The infrared spectra of mercapto-based bentonite and bentonite calcium-based soil are shown in figure 1 . Depend on figure 1 It can be seen that compared with calcium-based bentonite (MMT), mercapto-bentonite (MMT-SH) has a C-H stretching vibration peak at 2900, and an S-H stretching vibration peak at 2560. The changes ...

Embodiment 2

[0051] Example 2 Preparation of mercaptolated bentonite (2#), the mass ratio of bentonite to 3-mercaptopropyltrimethoxysilane is 1:0.1.

[0052] Weigh 2.00g bentonite raw soil into a 100mL small beaker, add 10mL 2% 3-mercaptopropyltrimethoxysilane ethanol solution and 0.12g sodium silicate powder, add a certain amount of distilled water to make the solid-liquid ratio of the system 1g : 20mL, mix well, adjust the pH of the solution to be 9.50~10.00, stir and react at room temperature for 6h, wash with distilled water until neutral, filter with suction, dry at 40°C, grind and pass through 80 mesh sieve to obtain thiolated bentonite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com