Preparation method and application of sepiolite composite adsorbent loaded with nano zinc sulfide

A technology of nano-zinc sulfide and composite adsorption, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of high activity, insufficient adsorption capacity, instability, etc., and achieve simple modification process, The effect of wide source of raw materials and wide promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

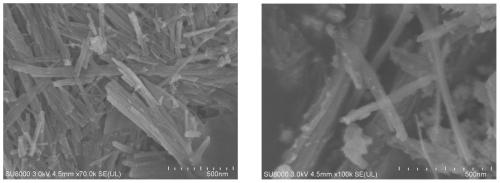

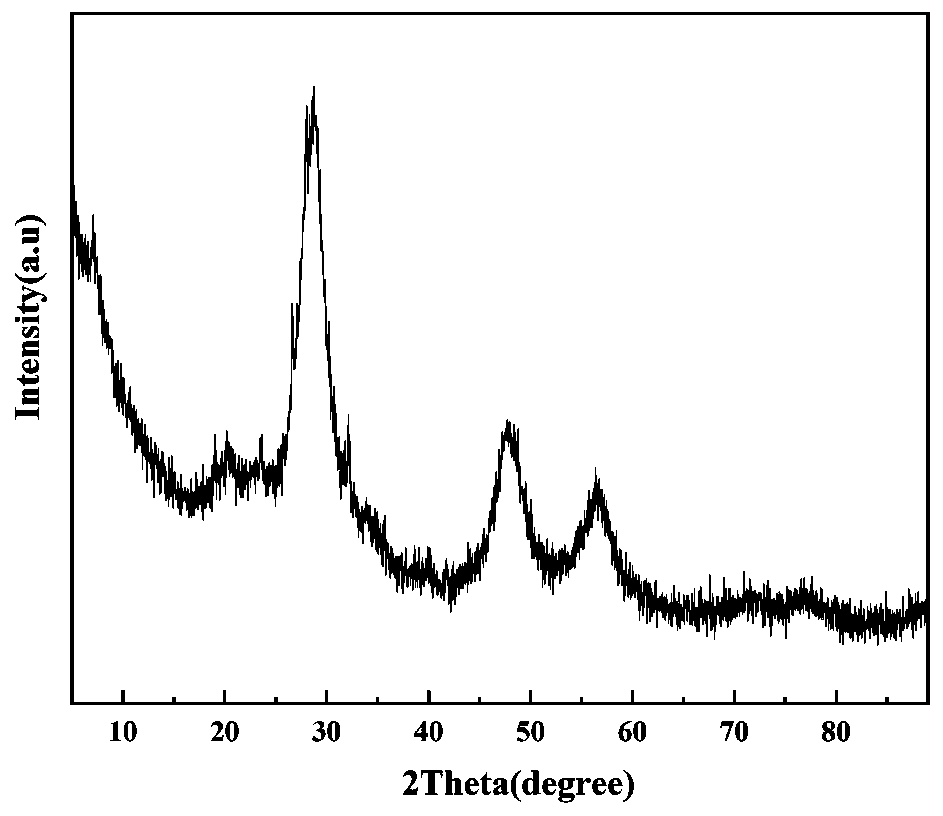

[0032] A method for preparing a nano zinc sulfide sepiolite composite adsorbent, comprising the following steps:

[0033] (1) Mix sepiolite with 1mol / L hydrochloric acid solution according to the solid-to-liquid ratio of 1:20, stir magnetically at 400rpm for 16 hours, rinse with deionized water, and centrifuge until the pH is close to 7, and then filter and place in a refrigerator at 105°C Dried in an oven for 2 hours, and ground through a 100-mesh sieve to obtain acid-modified sepiolite;

[0034] (2) Put the acid-modified sepiolite obtained in step (1) into a muffle furnace for high-temperature roasting, heat up at a rate of 5°C / min, reach the roasting temperature, and continue for 2 hours, and cool to room temperature after the roasting is completed. Obtain acid heat modified sepiolite;

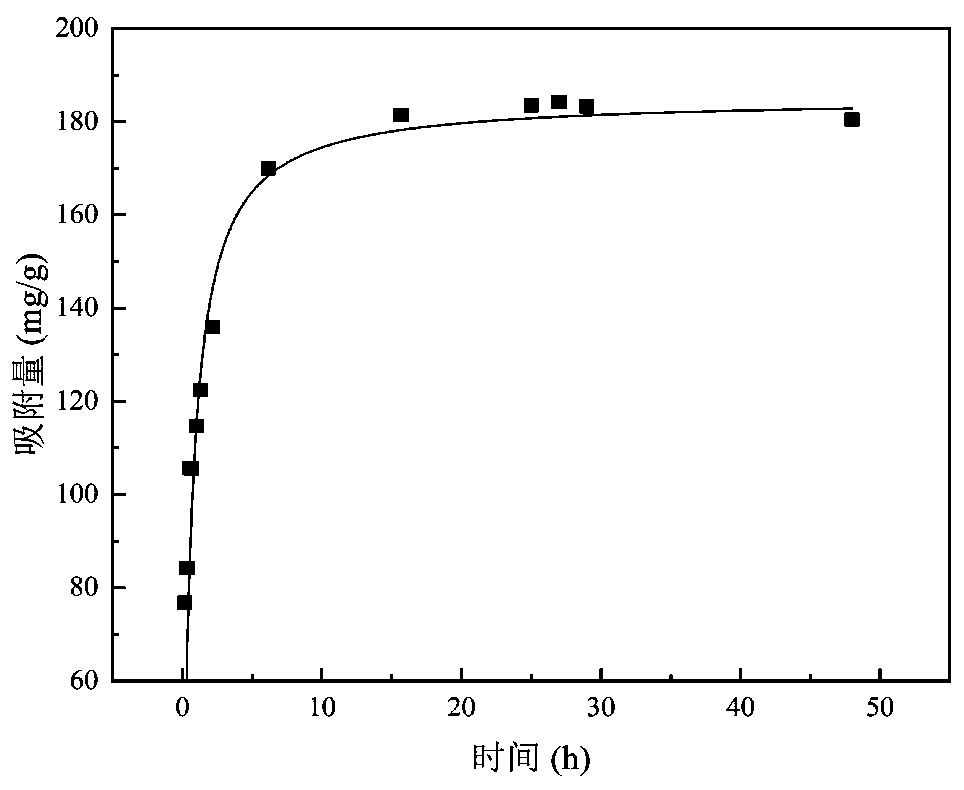

[0035] (3) The acid-heat modified sepiolite obtained in step (2) and the loaded ZnS are mixed in ZnSO with a mass ratio of 1:10 4 After soaking in the solution for 30min, drop Na 2 The S...

Embodiment 2

[0038] Other conditions are the same as in Example 1, except that in step (3), the mass ratio of the acid-heat modified sepiolite to the loaded ZnS is 1:5, and other conditions and test conditions are the same as in 1, and the sample is to Cd 2+ The adsorption capacity is 101.40mg / g. Compared with Example 1, it is poor.

Embodiment 3

[0040] Other conditions are the same as in Example 1, except that in step (3), the mass ratio of the acid-heat modified sepiolite to the loaded ZnS is 1:2, and other conditions and test conditions are the same as in 1, and the sample is to Cd 2+ The adsorption capacity is 144.77mg / g. Compared with Example 1, it is poor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com