Nanoparticle photocatalysis board, its preparation method and application thereof

A nanoparticle and catalytic plate technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as inability to guarantee anatase TiO2, low photocatalytic activity, and limited substrate selection , to achieve the effects of low production cost, low particle desorption rate, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

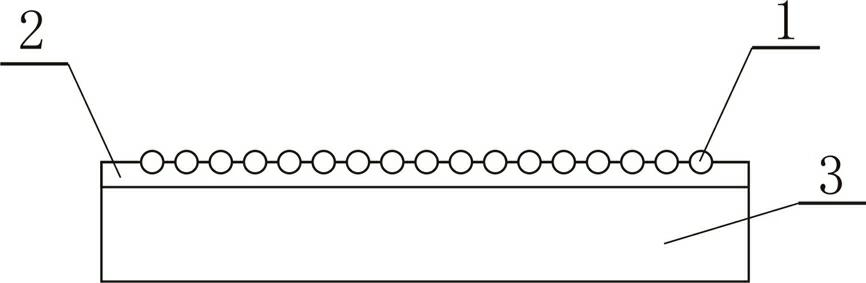

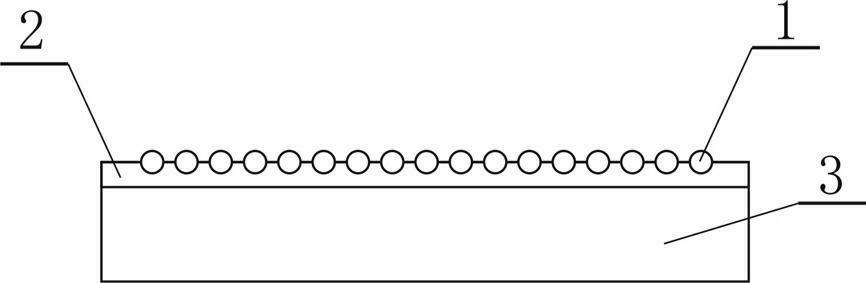

[0018] The photosensitive nanoparticle coating 1 is TiO 2 or ZnO nanoparticle coating.

[0019] The substrate 3 is a corrosion-resistant rough surface plate, which can be selected from frosted glass plate, rough stainless steel plate or foamed aluminum plate. In particular, the frosted glass plate as the substrate 3 has low cost, rough surface, large effective area, and is easy to be made into different shapes. The activity of the material itself is low, and it is not easy to react with the environment, which improves the stability of the photocatalytic plate. Substrates made of other corrosion-resistant materials can also achieve the purpose of the present invention.

[0020] The curing is UV glue curing.

[0021] The preparation method of the nanoparticle photocatalytic plate of the present invention comprises the following steps:

[0022] A. Dry the substrate 3 after ultrasonic cleaning;

[0023] B. Evenly apply light-curable adhesive on the cleaned substrate 3 to form ...

Embodiment 1

[0033] Use the frosted glass plate as the substrate 3 , ultrasonically clean and dry it for later use; dilute the UV curing adhesive with 70% alcohol to make a UV curing adhesive solution with a volume ratio of 5%; apply the UV curing adhesive solution evenly on the ground glass plate in a dark room Make a UV curable rubber sheet, dry it with hot air; then in a dark room, put TiO 2 The nanoparticles are evenly sprayed onto the UV-curable plastic sheet by an electrostatic powder sprayer, and then placed in an ultraviolet light environment for curing, which is the photocatalytic sheet of the present invention.

Embodiment 2

[0035] Use a rough stainless steel plate as the substrate 3, ultrasonically clean and dry it for later use; dilute the UV curing glue with 95% alcohol to make a UV curing glue solution with a volume ratio of 4%; apply the UV curing glue solution evenly on the rough surface in a dark room Unembroidered steel plate made of UV-cured rubber sheet, dry naturally; then in the dark room, the TiO 2 The nanoparticles are evenly sprayed onto the UV-curable rubber sheet with an electrostatic powder sprayer, and then placed in an ultraviolet light environment for curing to obtain a photocatalytic sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com