Pressurization gas dissolution type coal slime mixing device

A pressurized air-dissolving and pulping technology, applied in the direction of solid separation, etc., can solve the problem of effectively increasing the adhesion speed of target minerals and air bubbles in coal slime, increasing the difference in surface hydrophobicity between minerals, and reducing the concentration of target minerals and air bubbles. Bubble desorption probability and other issues to achieve the effect of improving unit processing capacity, reducing drug consumption, and enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

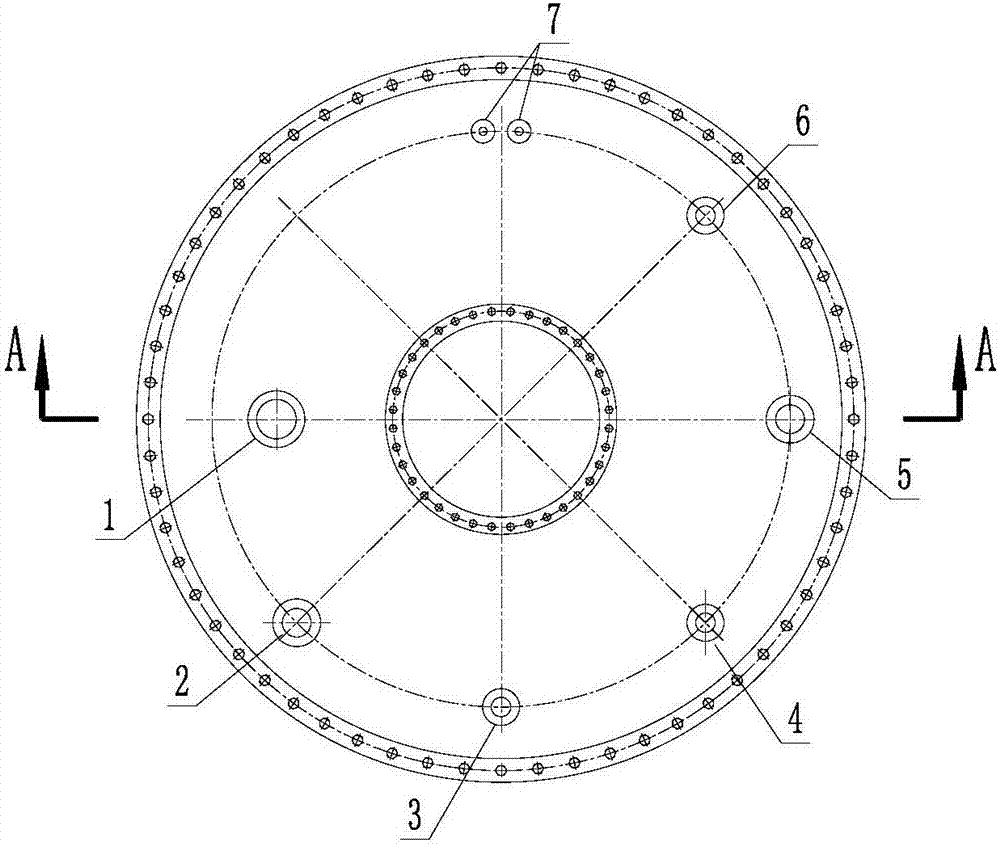

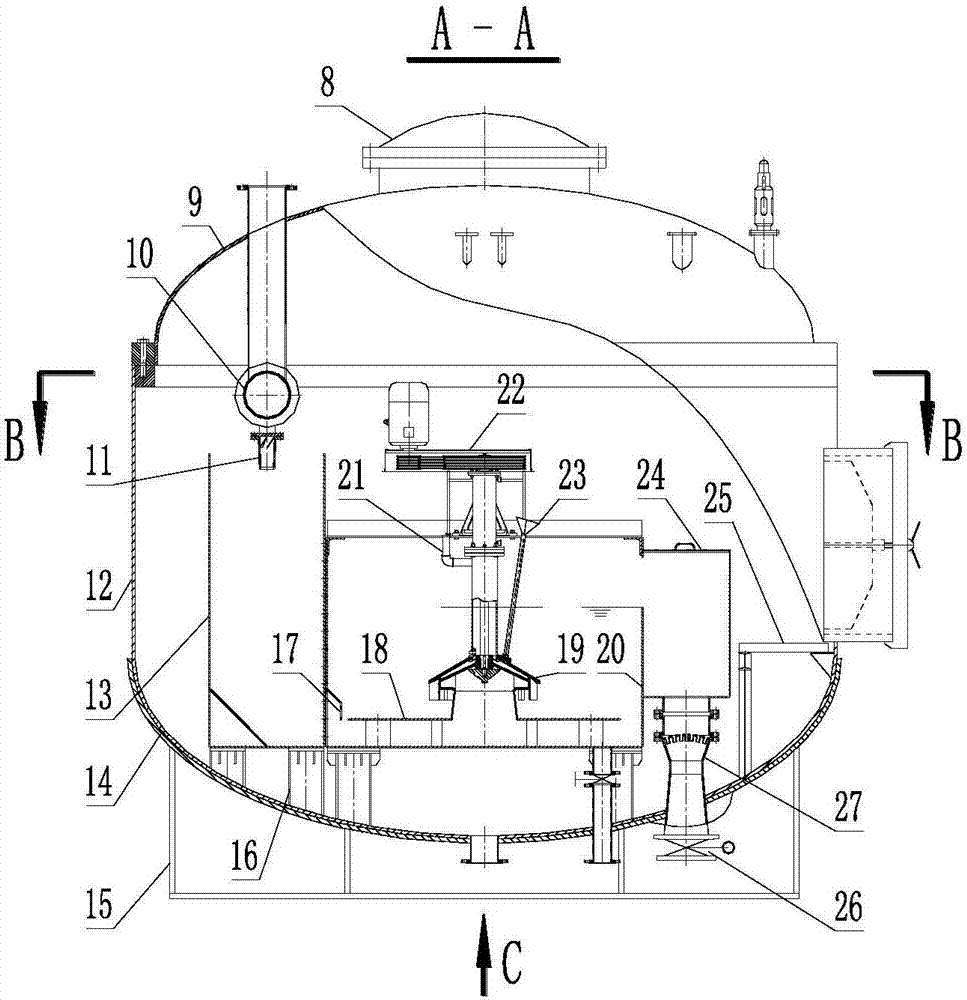

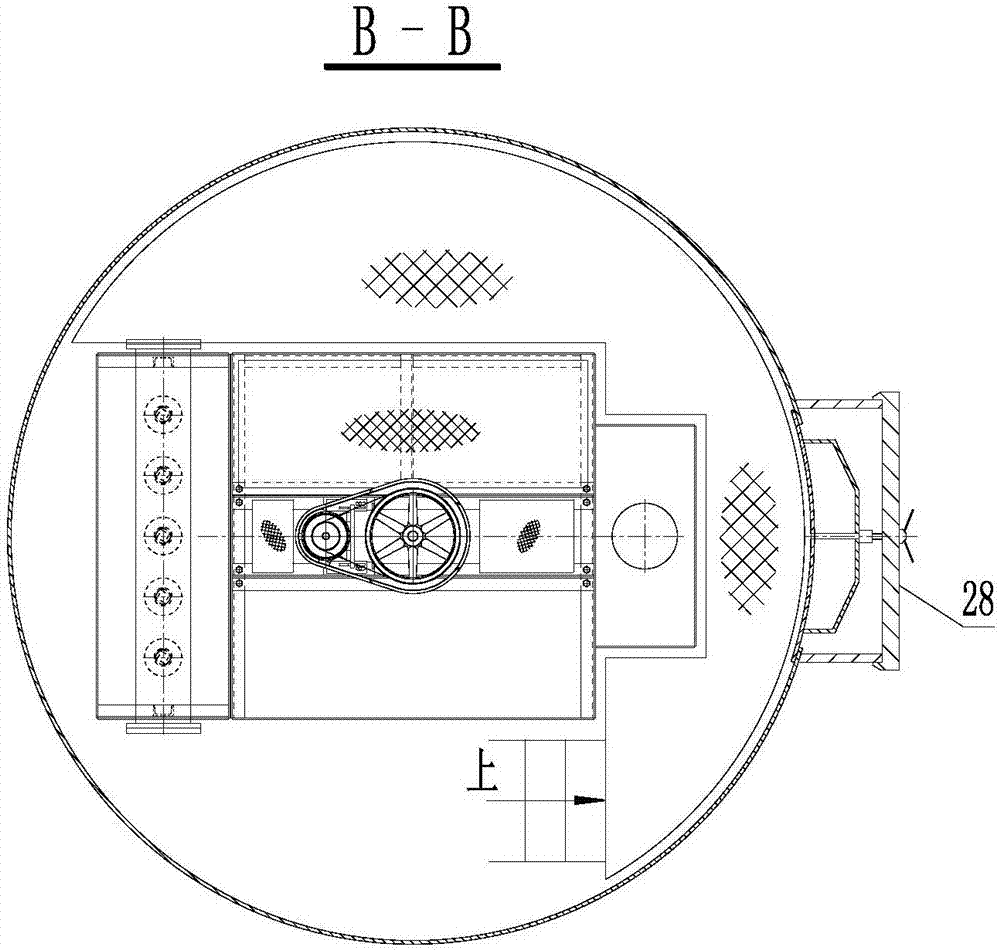

[0022] The present invention is composed of a pressurized chamber 12, a pulp feeding jet device, a stirring and pulping device, a decompression discharging device and an electric control system.

[0023] As shown in the figure, the pressurized chamber 12 is a cylindrical structure with ellipsoidal heads at both ends. The upper head 9 is flanged to the cylinder of the pressurized chamber 12 and is detachable. The lower head 14 is connected to the pressurized The cylinder body of the bin 12 is welded, and the slurry feeding jet device, the stirring and mixing device and the decompression discharging device are all installed in the pressurized bin 12 .

[0024] As shown in the figure, the pressurized chamber 12 is supported by two saddles 15, and the lower plane of the saddles 15 directly acts on the load-bearing beam. The upper head 9 of the pressurized chamber 12 is detachable, and large parts such as the pulp jet and the stirring and mixing device can be loaded from here. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com