Batch type photocatalytic energy collection reactor and method for wastewater treatment by same

A technology for energy collection and wastewater treatment, applied in chemical instruments and methods, special compound water treatment, light water/sewage treatment, etc. Simple structure, saving floor space, and increasing the effect of degradation degree and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

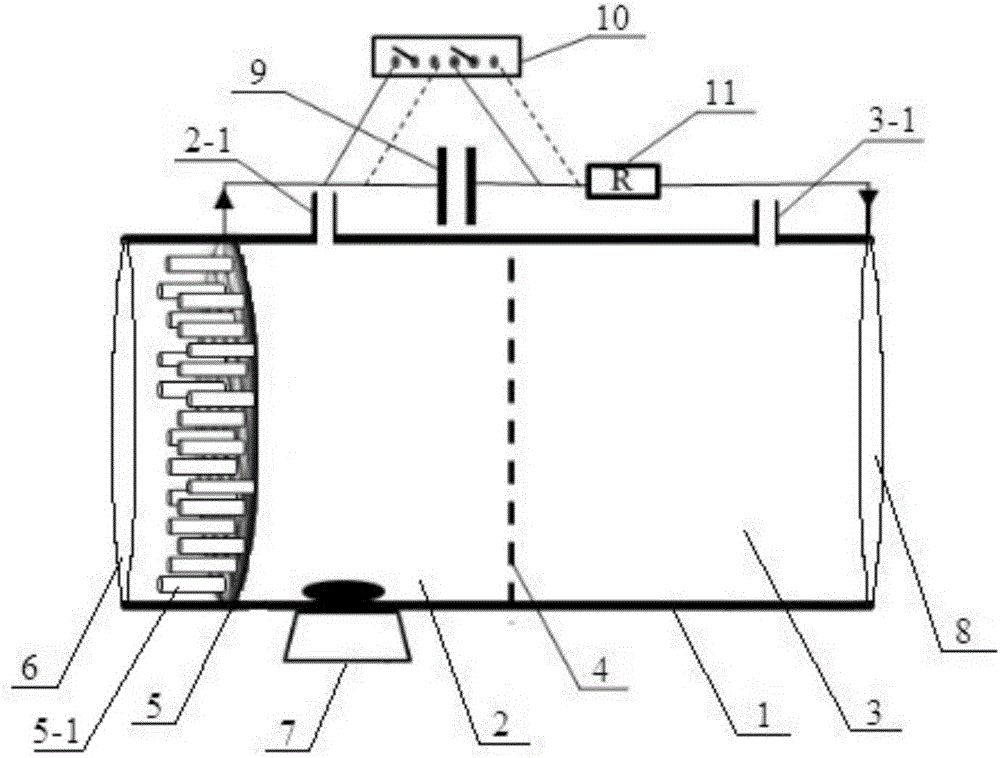

[0027] Specific implementation mode one: combine figure 1 Describe this embodiment, the intermittent photocatalytic energy harvesting reactor of this embodiment comprises housing 1, anode chamber 2, cathode chamber 3, proton exchange membrane 4, photoanode 5, quartz glass 6, stirring device 7, counter electrode 8, capacitor 9 and converter 10,

[0028] A proton exchange membrane 4 is provided in the middle of the housing 1, and the proton exchange membrane 4 divides the inner chamber of the housing 1 into an anode chamber 2 and a cathode chamber 3, and a photoanode 5 is provided on the housing 1 at one end of the anode chamber 2, and the housing 1 The upper end of the cathode chamber 3 is provided with a counter electrode 8, the photoanode 5 is covered with quartz glass 6, the inner bottom of the anode chamber 2 is provided with a stirring device 7, and the housing 1 is located on the side of the anode chamber 2. An anode chamber water inlet 2- 1. On the side of the cathode c...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment is different from Embodiment 1 in that: the housing 1 is a flat cylinder or cuboid. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the photoanode 5 is an n-type semiconductor photocatalytic material or an n-type semiconductor photocatalytic material loaded with active substances, and the photoanode 5 is loaded with active substances One side faces the quartz glass; the loaded active material is a material capable of photocatalytically modifying the semiconductor to increase the photocatalytic performance. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com