Mine pit backfill material as well as preparation method and application thereof

A technology for pits and raw materials, applied in mining equipment, fillings, earthwork drilling, etc., can solve the problems of polluted water sources and difficult to deal with, and achieve the effect of low backfilling cost and improving mineralization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

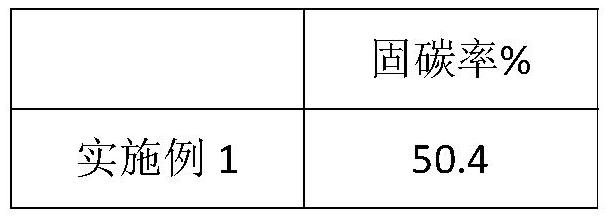

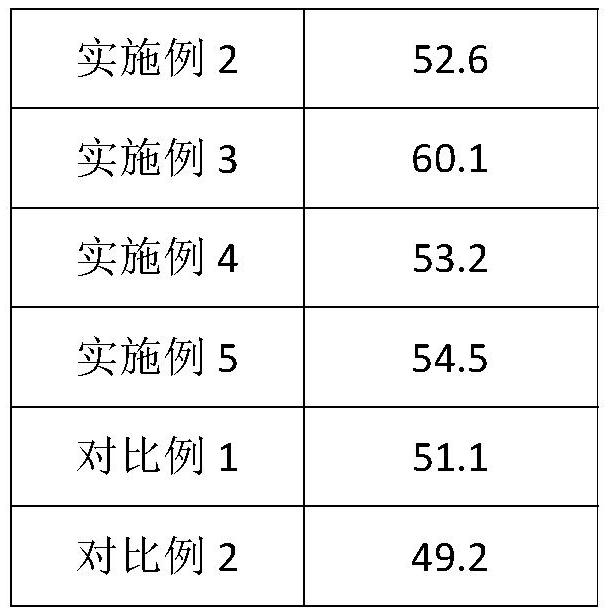

Embodiment 1

[0029] Embodiment 1 A kind of pit backfill material and preparation method

[0030] A mine pit backfill material is composed of the following raw materials in parts by weight:

[0031] 25 parts of industrial solid waste, 170 parts of water, 1 part of sodium dodecylbenzene sulfonate, 1 part of polyvinyl alcohol and 8 parts of cement.

[0032] The preparation method of described pit backfill material comprises the following steps:

[0033] S1. Industrial solid waste is pulverized to obtain raw materials with a particle size of 20 microns;

[0034] S2. Hydrating and calcining the raw material obtained in step S1 with 100 parts of water to obtain a sample;

[0035] The treatment conditions for the hydration calcination are: stirring at 25°C for 5h, drying treatment, and calcination at 400°C for 3h;

[0036] S3. Stir the sample obtained in step S2 with sodium dodecylbenzenesulfonate, polyvinyl alcohol and the remaining amount of water to form a slurry, inject 30% carbon dioxide,...

Embodiment 2

[0038] Embodiment 2 A kind of pit backfill material and preparation method

[0039] A mine pit backfill material is composed of the following raw materials in parts by weight:

[0040] 30 parts of industrial solid waste, 210 parts of water, 3 parts of sodium dodecylbenzene sulfonate, 5 parts of polyvinyl alcohol and 12 parts of cement.

[0041] The preparation method of described pit backfill material comprises the following steps:

[0042] S1. Industrial solid waste is pulverized to obtain raw materials with a particle size of 400 microns;

[0043] S2. Hydrating and calcining the raw material obtained in step S1 with 120 parts of water to obtain a sample;

[0044] The treatment conditions for the hydration calcination are: stirring at 50°C for 2h, drying treatment, and calcination at 800°C for 1h;

[0045] S3. Stir the sample obtained in step S2 with sodium dodecylbenzenesulfonate, polyvinyl alcohol and the remaining amount of water to form a slurry, inject 100% carbon dio...

Embodiment 3

[0047] Embodiment 3 A kind of pit backfill material and preparation method

[0048] A mine pit backfill material is composed of the following raw materials in parts by weight:

[0049] 29 parts of industrial solid waste, 200 parts of water, 2 parts of sodium dodecylbenzene sulfonate, 3 parts of polyvinyl alcohol and 9 parts of cement.

[0050] The preparation method of described pit backfill material comprises the following steps:

[0051] S1. Industrial solid waste is pulverized to obtain raw materials with a particle size of 100 microns;

[0052] S2. Hydrate and calcinate the raw material obtained in step S1 with 115 parts of water to obtain a sample;

[0053] The treatment conditions for the hydration calcination are: stirring at 30°C for 3h, drying treatment, and calcination at 600°C for 2h;

[0054] S3. Stir the sample obtained in step S2 with sodium dodecylbenzenesulfonate, polyvinyl alcohol and the remaining amount of water to form a slurry, inject 80% carbon dioxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com