Mineral filter material, preparation method thereof, filter element with mineral filter material and water quality mineralization method of filter element

A technology of minerals and filter materials, applied in water/sewage treatment of added substances, chemical instruments and methods, filtration treatment, etc., can solve the problems of slow dissolution rate of minerals, uncontrollable dissolution rate, etc. The effect of improving the dissolution rate and accelerating the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

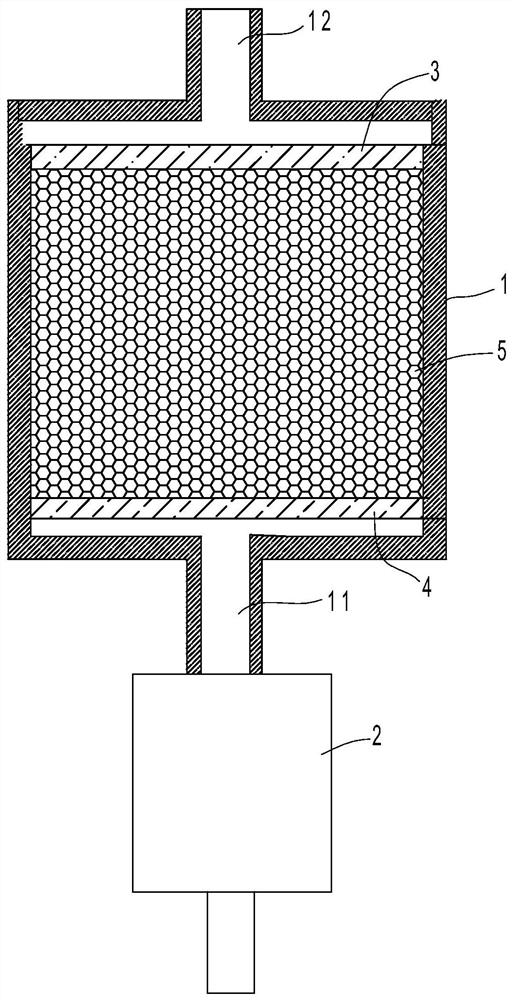

Image

Examples

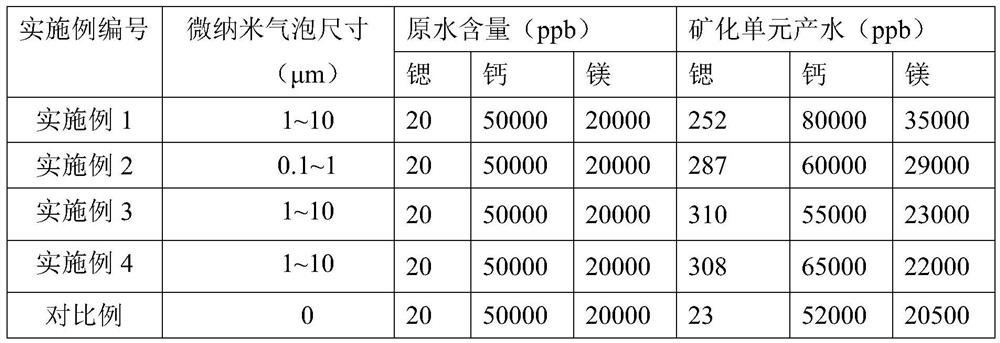

Embodiment 1

[0039] Example 1, each component in the mineralized material is weighed in the following weight ratios: 25% of medical stone, 15% of secondary quartz stone, 40% of feldspar quartz sandstone, and 20% of rhodochrosite. The embedding material contains 50% zeolite, 25% calcium carbonate and 25% magnesium carbonate. The weight ratio of mineralized material and embedding material is 1:5.

[0040] Above-mentioned raw material is processed with following preparation method:

[0041] 1) Grinding and mixing the mineralized material, putting it into water to form a suspension;

[0042] 2) Add the embedding material to the suspension, stir and mix evenly, and evaporate the water to achieve the mixed slurry;

[0043] 3) drying the mixed slurry, and then performing ball milling to prepare pellets and drying;

[0044] 4) Put the pellets into a high-temperature kiln, raise the temperature to 800° C. under the protection of nitrogen, and heat-preserve and fire for 4 hours to prepare the min...

Embodiment 2

[0048] Example 2, each component in the mineralized material is weighed in the following weight ratios: 30% of medical stone, 15% of secondary quartz stone, 30% of feldspar quartz sandstone, and 25% of rhodochrosite. The embedding material contains 50% zeolite, 20% calcium carbonate and 30% magnesium carbonate. The weight ratio of mineralized material and embedding material is 1:10.

[0049] Above-mentioned raw material is processed with following preparation method:

[0050] 1) Grinding and mixing the mineralized material, putting it into water to form a suspension;

[0051]2) Add the embedding material to the suspension, stir and mix evenly, and evaporate the water to achieve the mixed slurry;

[0052] 3) drying the mixed slurry, and then performing ball milling to prepare pellets and drying;

[0053] 4) Put the pellets into a high-temperature kiln, raise the temperature to 1000° C. under the protection of nitrogen, and heat-preserve and fire for 2 hours to prepare the mi...

Embodiment 3

[0056] Example 3, each component in the mineralized material is weighed in the following weight ratios: 60% of medical stone, 10% of secondary quartz stone, 5% of feldspar quartz sandstone, and 5% of rhodochrosite. The embedding material contains 60% zeolite, 25% calcium carbonate and 15% magnesium carbonate. The weight ratio of mineralized material and embedding material is 1:2.

[0057] Above-mentioned raw material is processed with following preparation method:

[0058] 1) Grinding and mixing the mineralized material, putting it into water to form a suspension;

[0059] 2) Add the embedding material to the suspension, stir and mix evenly, and evaporate the water to achieve the mixed slurry;

[0060] 3) drying the mixed slurry, and then performing ball milling to prepare pellets and drying;

[0061] 4) Put the pellets into a high-temperature kiln, raise the temperature to 1000° C. under the protection of nitrogen, and heat-preserve and fire for 4 hours to prepare the mine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com