Jet atomization device and flotation device with same

A technology of spray atomization and atomization cylinder, which is applied in the direction of spray device, liquid spray device, mixer with rotating container, etc., which can solve the problem that the surfactant-foaming agent cannot be fully dispersed and the effect cannot be mixed by flotation minerals , microbubble system instability and other problems, to achieve the effect of improving mineralization efficiency, improving flotation effect and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

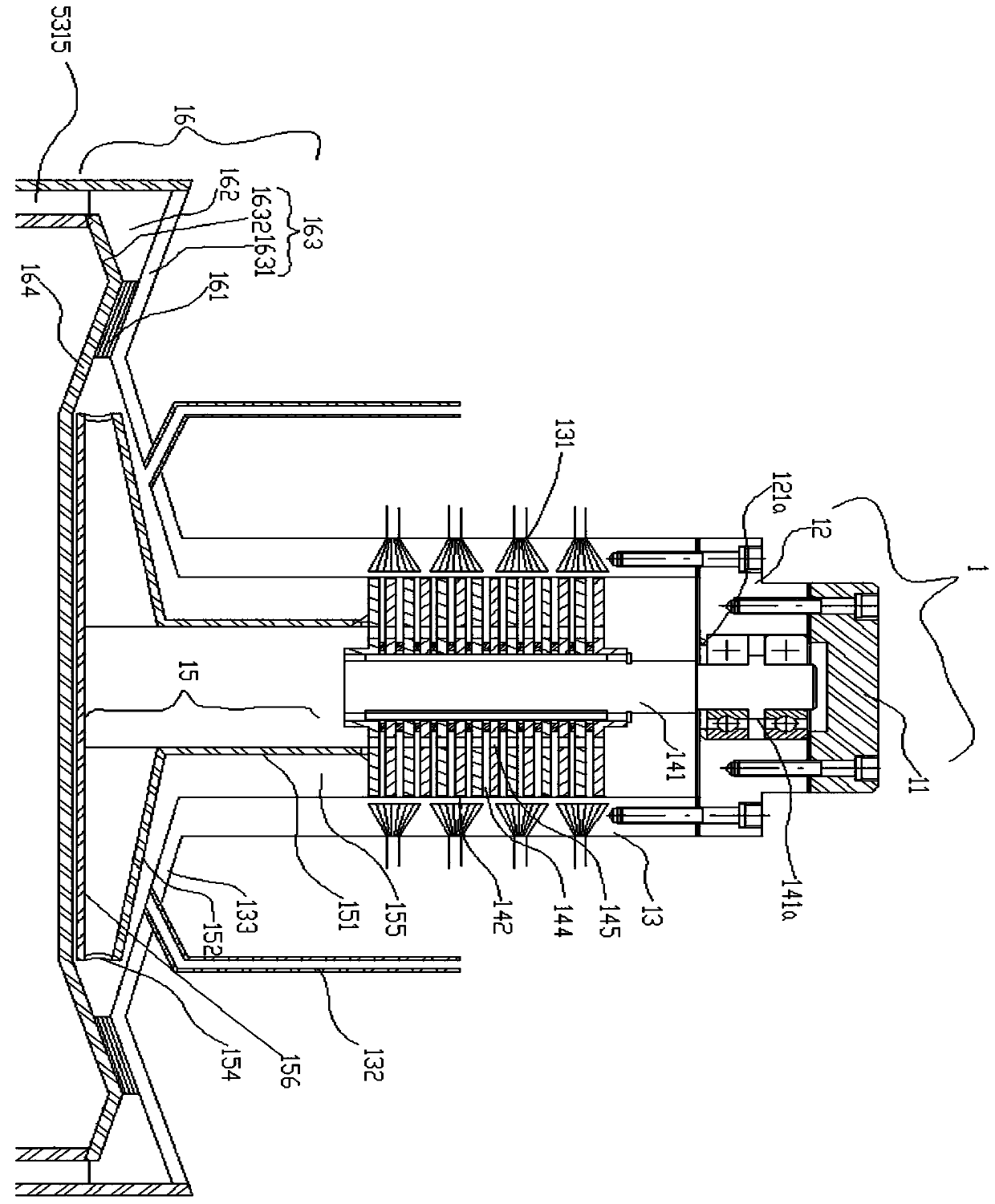

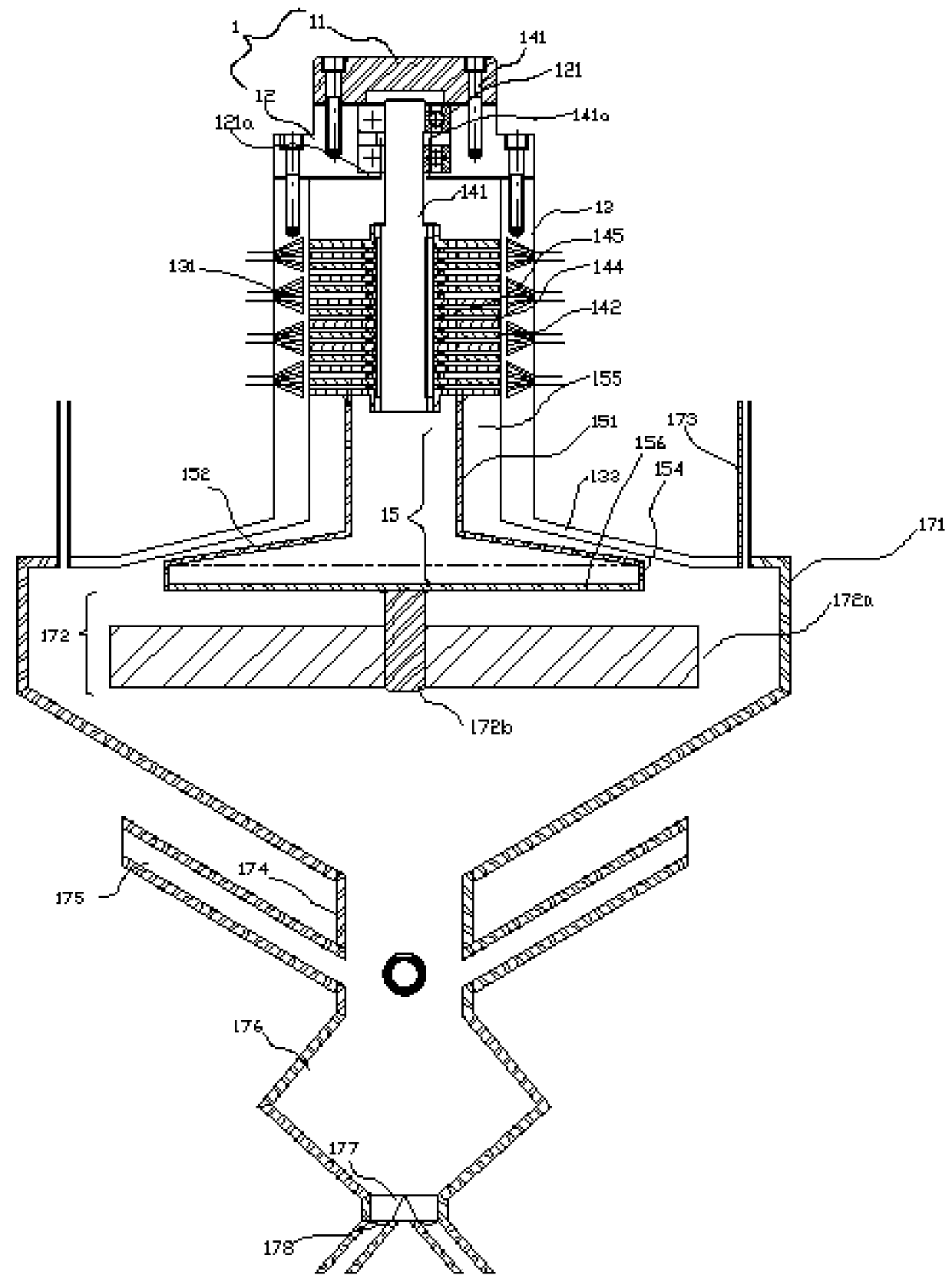

[0068] Embodiment 1: A spray atomization device, comprising: an atomization cylinder 13, a rotating shaft 141, a laminar flow deflector 142 and an atomization turntable 15, the upper end of the atomization cylinder 13 is provided with a cover 1; the rotation axis 141 is along the atomization The barrel 13 is arranged in the atomizing barrel 13 in the axial direction, and its upper end is rotatably connected with the cover 1 through a bearing;

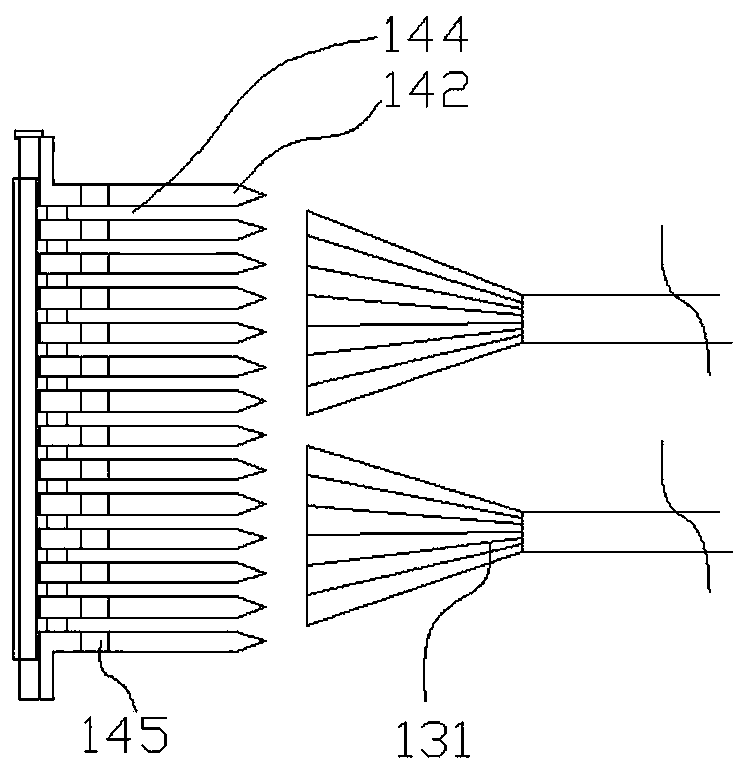

[0069] The laminar flow guide plate 142 is multi-layered, and the middle part is provided with a mounting hole. The multiple laminar flow guide plates 142 are fixed on the rotating shaft 141 at intervals and have a discharge hole 145 on it. Two adjacent layers of laminar flow guide A shear drive layer 144 is formed between the disks 142;

[0070] The position corresponding to the shear driving layer 144 on the side wall of the atomizing cylinder 13 is provided with a jet diverter pipe 131, and the liquid ejected from the jet diverter pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com