Visual detection system and detection method for LED lamp filament spot-welding correction

A technology for LED filament and visual inspection, applied in the field of visual inspection system, can solve the problems of unstable quality, low efficiency of LED filament production method, low product accuracy, etc., and achieve the effect of improving welding accuracy and improving sorting speed and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

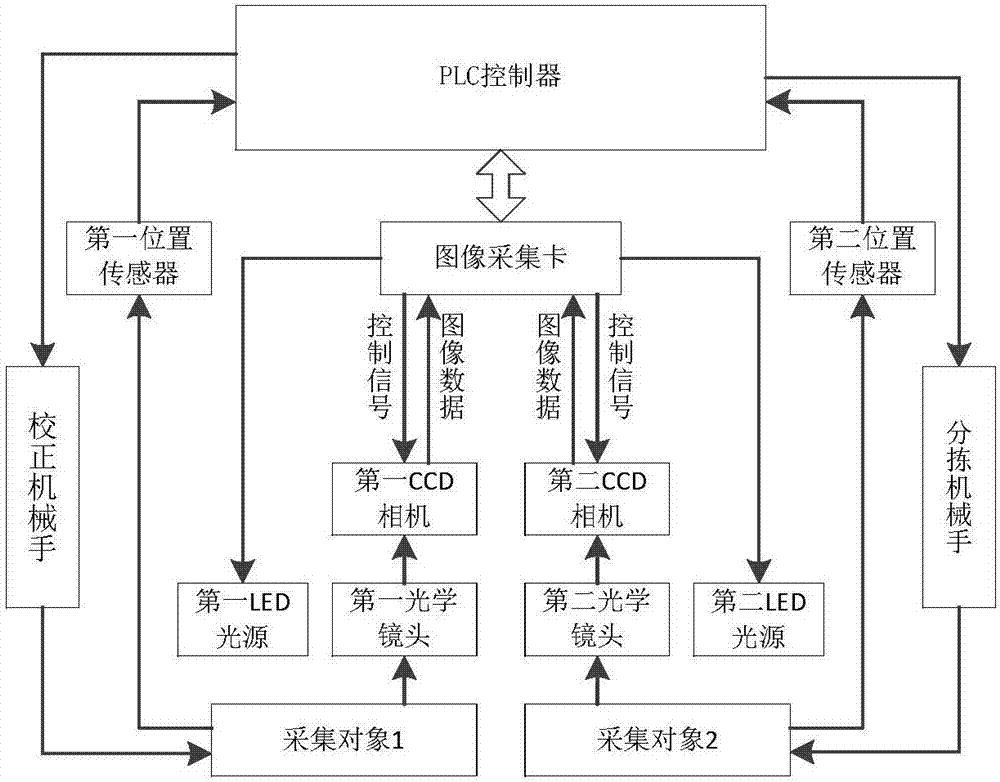

[0037] Such as figure 1 As shown, a visual detection system for LED filament spot welding, including: PLC controller, image acquisition card, first position sensor, second position sensor, calibration manipulator, sorting manipulator, first LED light source, second LED light source, first optical lens, second optical lens, first CCD camera, second CCD camera. The first CCD camera, the second CCD camera, the first optical lens, the second optical lens, the first LED light source, and the second LED light source jointly form a visual acquisition system, and the welding process Image acquisition with the products of the sorting process.

[0038] The image acquisition card is directly connected with the first LED light source and the second LED light source, the first CCD camera and the second CCD camera, and the image acquisition card controls the first LED light source and the second LED light source. The switch of the second LED light source is used to cooperate with the acqu...

Embodiment 2

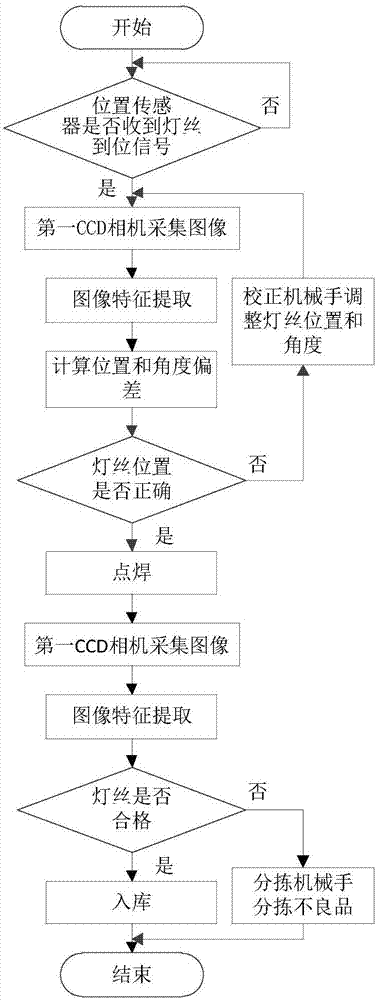

[0046] Such as figure 2 As shown, a visual detection method for LED filament spot welding correction, the specific workflow is as follows: When the acquisition object 1 reaches the designated welding position, the first position sensor will send the "detected object" message to the PLC controller Pulse signal, the PLC controller sends a trigger signal to the image acquisition card after calculation. After the image acquisition card detects this signal, it will immediately send an image acquisition command to the first CCD camera, and at the same time control the opening of the first LED light source. The first CCD camera transmits the collected image signal back to the image acquisition card, and the image acquisition card passes the image signal to the PLC controller to obtain the position deviation signal after processing, and the PLC controller processes the position deviation signal and sends correction to the calibration manipulator Signal, after the acquisition object i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com