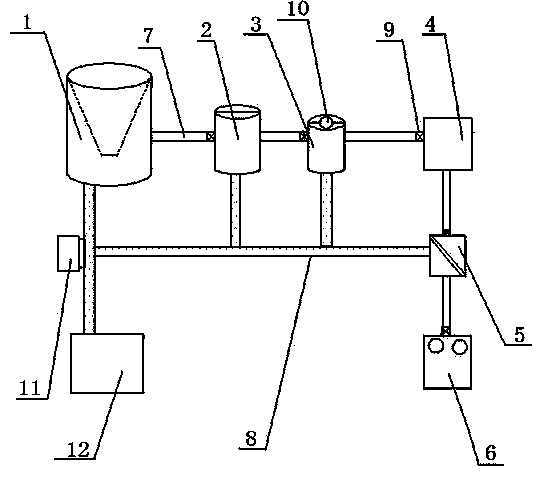

Mineral processing water-saving and emission reduction device and method

A technology of equipment and tailings pool, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor purification quality and low recovery rate, and reduce the impact of pollution , The effect of reducing the impurity content and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

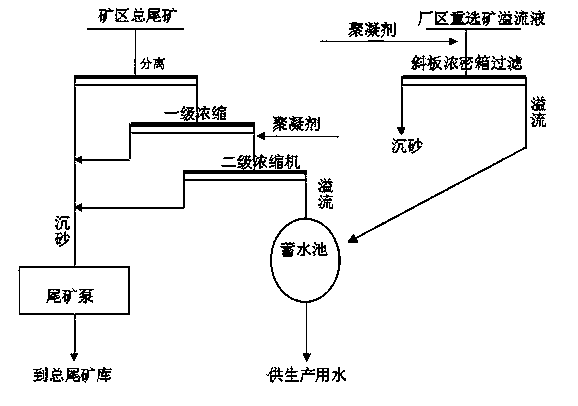

[0039] (1) The production scale of a factory is 1200t / d of tailings, and the production water consumption is 635m 3 / h, and most of its water supply is provided by the water source of the newly built pre-plant circulation system.

[0040] (2) The new φ18m-φ24m concentrator circulation return system can provide 475 m 3 / h, and put an end to the overflow of the φ24m concentrator into the green pond, reducing environmental pollution. In order to ensure that the clarity of the overflow water of the φ18m thickener meets the requirements of production volume, 45g / min of polyacrylamide cellulose is added to the overflow position of the φ24m thickener.

[0041] (3) An additional 800m in the factory 2 High-efficiency slanted-plate thickener capable of generating 153 m in situ 3 / h produced water, in order to ensure that the clarity of the overflow water of the high-efficiency thickening tank meets the production requirements, 25g / min of polyacrylamide cellulose is added to the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com