Method for separating potassium feldspar ore concentrate and iron ore concentrate from Baiyunebo potassium rich slate

A technology of potassium-rich slate and potassium feldspar, which is applied in the field of separating potassium-feldspar concentrate and iron concentrate from Baiyun Obo potassium-rich slate, can solve the problems of no industrial production and achieve the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

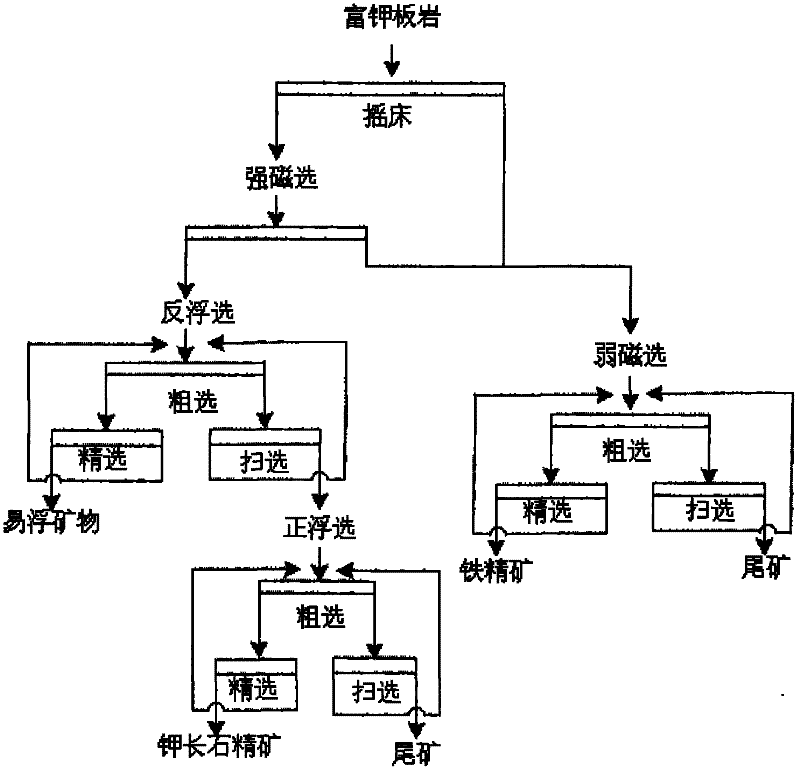

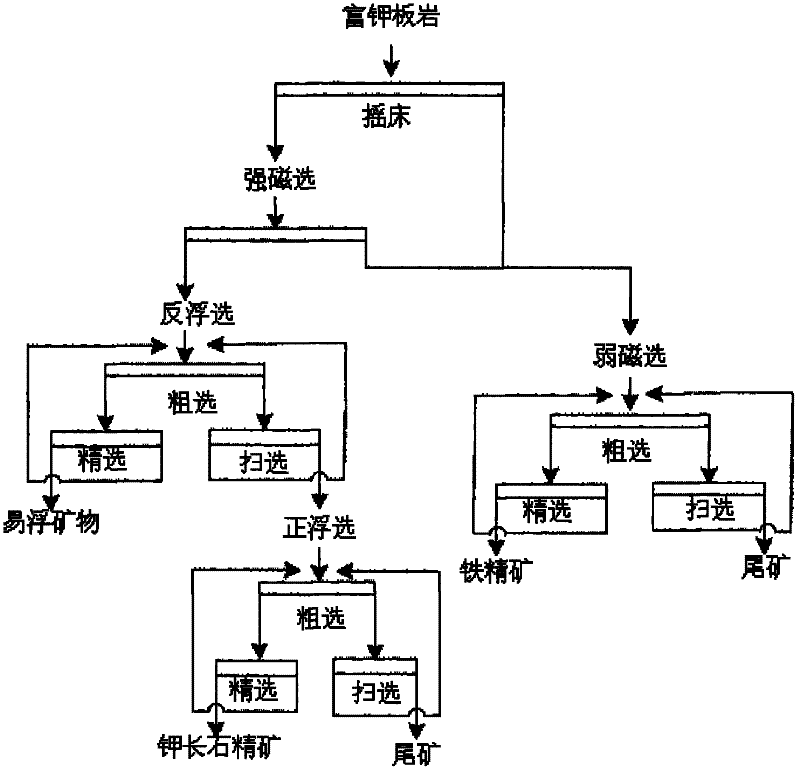

[0022] A Baiyun Obo potassium-rich slate with a grain size of -200 mesh accounting for more than 90%, a potassium feldspar content of 67.65%, and a magnetite grade of 6.1% is subjected to the following operations by using the process of the present invention:

[0023] (1) Gravity separation: Slurry the raw material with water so that the weight concentration of the pulp is 10%, the water temperature is 10°C, and the shaking table mineral processing method is used to obtain heavy minerals and light minerals.

[0024] (2) Strong magnetic separation: The light minerals obtained by gravity separation are subjected to strong magnetic separation to obtain magnetic minerals and non-magnetic minerals, and the magnetic field strength is 1.1T.

[0025] (3) Weak magnetic separation: the heavy minerals selected by the shaker and the magnetic minerals selected by the strong magnetic separation are combined for weak magnetic separation; the weak magnetic separation adopts the process of one ...

Embodiment 2

[0029] A kind of Baiyan Obo potassium-rich slate with a grain size of -200 mesh accounting for more than 90%, a potassium feldspar content of 64.25%, and a magnetite grade of 6.4% uses the process of the present invention to carry out the following operations:

[0030] (1) Gravity separation: Slurry the raw material with water, the water temperature is 8°C, the weight concentration of the pulp is 10%, and the shaking table mineral processing method is adopted to obtain heavy minerals and light minerals.

[0031] (2) Strong magnetic separation: The light minerals obtained by gravity separation are subjected to strong magnetic separation to obtain magnetic minerals and non-magnetic minerals, and the magnetic field strength is 1.2T.

[0032](3) Weak magnetic separation: Combine the heavy minerals selected by the shaking table and the magnetic minerals selected by the strong magnetic separation for weak magnetic separation; The magnetic field strength for selection is 0.25T, and t...

Embodiment 3

[0036] A kind of Baiyun Obo potassium-rich slate with a grain size of -200 mesh accounting for more than 90%, a potassium feldspar content of 65.82%, and a magnetite grade of 6.8% uses the process of the present invention to carry out the following operations:

[0037] (1) Gravity separation: Slurry the raw material with water, the water temperature is 35°C, the weight concentration of the pulp is 20%, and the shaking table mineral processing method is used to obtain heavy minerals and light minerals.

[0038] (2) Strong magnetic separation: The light minerals obtained by gravity separation are subjected to strong magnetic separation to obtain magnetic minerals and non-magnetic minerals, and the magnetic field strength is 1.0T.

[0039] (3) Weak magnetic separation: Combine the heavy minerals selected by the shaking table and the magnetic minerals selected by the strong magnetic separation for weak magnetic separation; The magnetic field strength for selection is 0.26T, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com