Bridge bored pile hole wall opening protection method

A technology of bored piles and hole walls, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., and can solve problems such as limitations or limitations, potential safety hazards, and construction difficulties, and achieve low prices, convenient materials, and mechanical The effect of less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

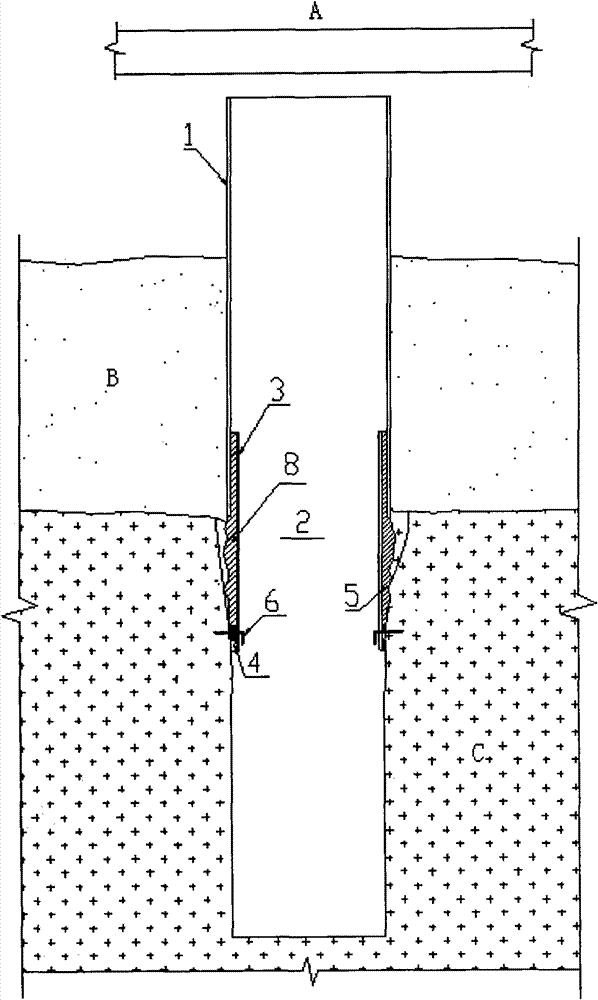

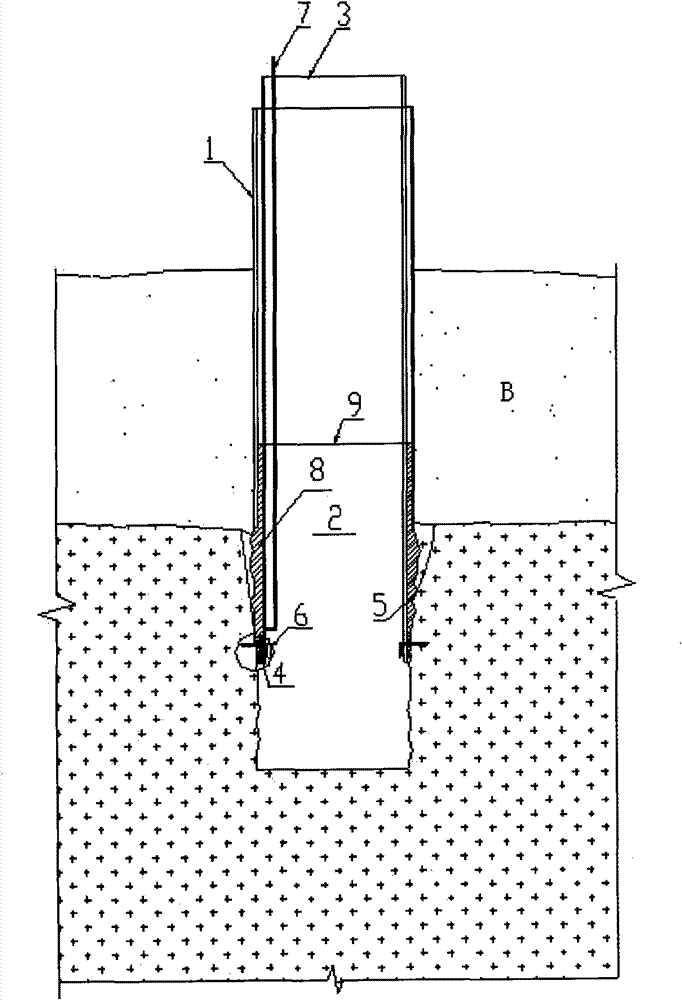

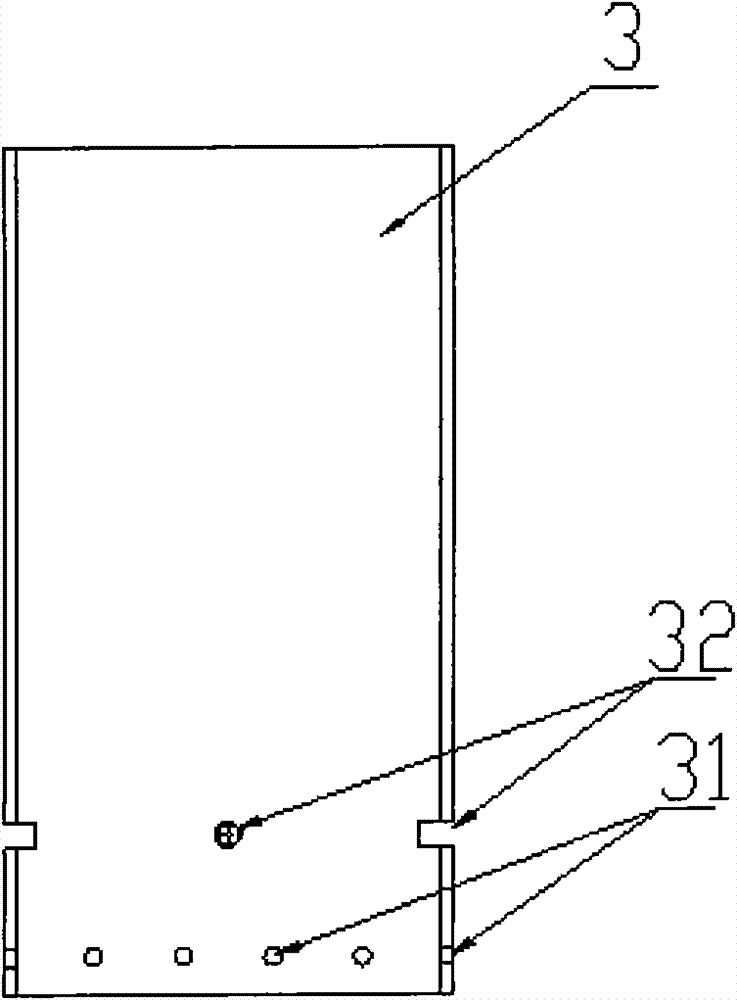

[0030] Please refer to figure 1 and figure 2 , a kind of bridge bored pile hole wall opening protection method of the present invention is used for the bridge bored pile hole wall opening protection with sandy soil cover layer, broken rock formation, and it comprises the following steps:

[0031] a. Before the construction of bridge bored piles, build the construction platform A;

[0032] b. Insert the steel casing 1 on the construction platform A, so that the steel casing 1 passes through the sandy soil cover layer B to the broken rock layer C and embeds the broken rock layer C to a certain depth; the steel casing 1 can be embedded into the broken rock layer C to a certain depth. Block the local small quicksand channel caused by the uneven rock surface of the broken rock layer C, prevent the pile hole from connecting with the outer sand covering layer in the early stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com