Method for recovering garnet and omphacite from eclogite ore

A technology for garnet and omphacite, applied in the field of recycling garnet and omphacite in eclogite mines, can solve the problem of poor effect, high garnet and omphacite concentrate products, and omphacite concentrate indicators To achieve the effect of simple process flow, stable sorting index and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

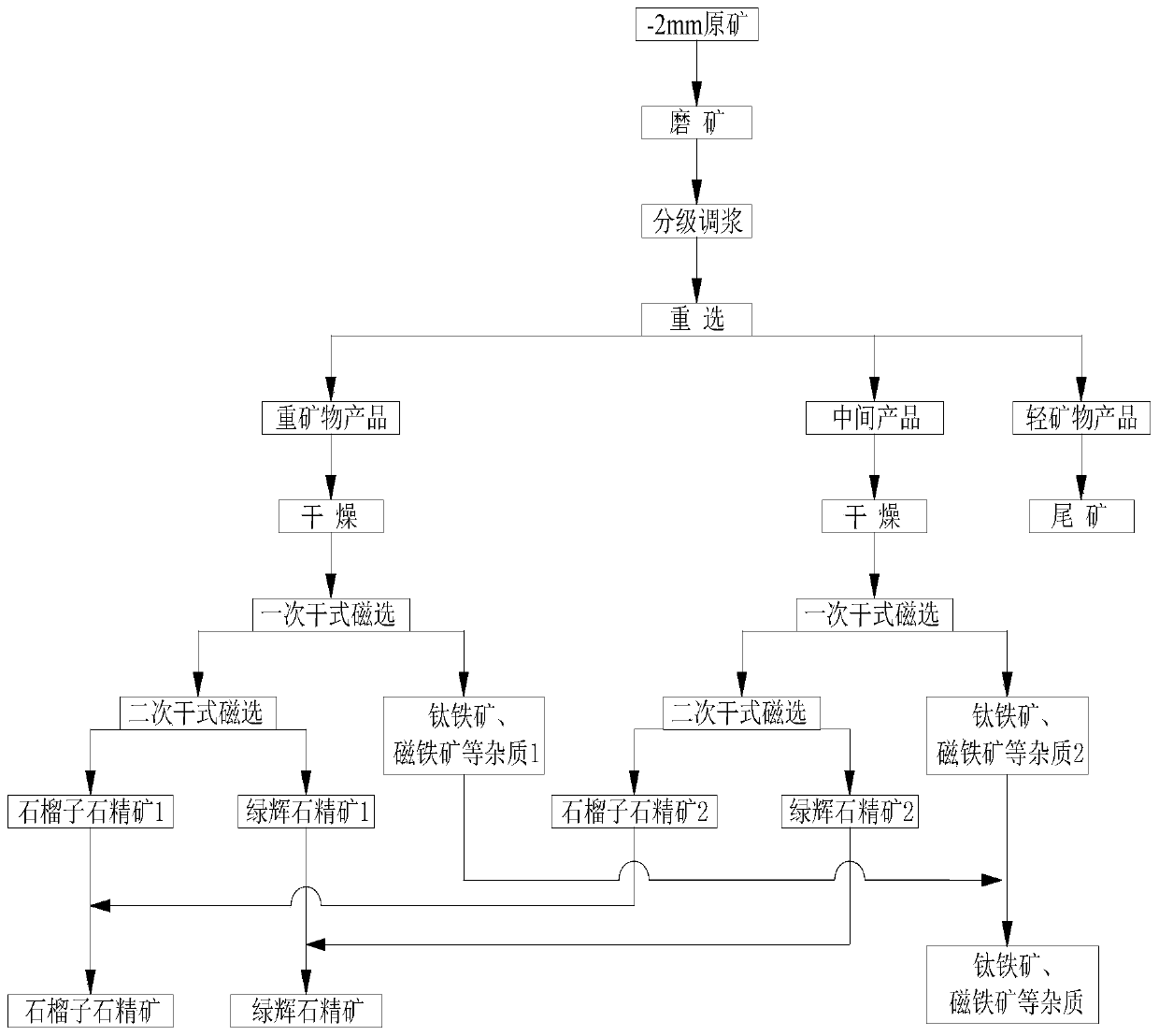

[0034] The eclogite ore in this embodiment is mined from Rizhao, Shandong. Analysis of the raw ore shows that the mineral content of garnet in the ore is 51.60%, and that of omphacite is 28.50%. The beneficiation technological process of present embodiment refers to attached figure 1 As shown, the -2mm raw ore is obtained by crushing and then ground, the grinding fineness is -0.074mm and the content is 35% (mass content, the same below). Sieve and classify the grinding products and divide them into three grades of +0.3mm, 0.1~0.3mm and -0.1mm; pulp the +0.3mm grade into a pulp with a concentration of 20%, adjust the 0.1~0.3mm grade Pulp into a pulp with a concentration of 25%, and pulp with a particle size of -0.1mm into a pulp with a concentration of 25%.

[0035]Gravity separation of +0.3mm pulp (gravity separation equipment is a spiral chute) to obtain +0.3mm heavy mineral products, +0.3mm intermediate products and +0.3mm light mineral products, +0.3mm light mineral produc...

Embodiment 2

[0043] Embodiment 2 is basically the same as Embodiment 1, the difference is that the eclogite ore of the present embodiment is mined from Donghai, Jiangsu, and the analysis of the raw ore shows that the mineral content of garnet in the ore is 45.60%, and the mineral content of omphacite is 45.60%. is 35.30%. The strength of the weak magnetic separation magnetic field for heavy mineral products and intermediate products of each particle size is 0.35T, and the strength of the strong magnetic separation magnetic field is 0.8T.

[0044] The separation indexes of each garnet and omphacite concentrate in this embodiment are shown in Table 2.

[0045] Table 2 embodiment 2 each garnet and omphacite concentrate sorting index / %

[0046] product name

[0047] The total yield of garnet concentrate (the garnet concentrates of all sizes are combined) is 42.70%, the mineral content is 91.73%, and the mineral recovery rate is 85.89%; ) The yield is 32.97%, the mineral content is ...

Embodiment 3

[0049] Example 3 is basically the same as Example 1, the difference is that the eclogite ore of this example is collected from Ulan, Qinghai, and the analysis of the raw ore shows that the mineral content of garnet in the ore is 50.70%, and the mineral content of omphacite The content is 23.68%. The strength of the weak magnetic separation magnetic field for heavy mineral products and intermediate products of each particle size is 0.30T, and the strength of the strong magnetic separation magnetic field is 0.75T. The separation indicators of each garnet and omphacite concentrate in this embodiment are shown in Table 3.

[0050] Table 3 embodiment 3 each garnet and omphacite concentrate selection index / %

[0051] product name

Yield

mineral content

Mineral Recovery

+0.3mm garnet concentrate

4.33

87

7.43

0.1~0.3mm garnet concentrate

34.21

92

62.08

-0.1mm garnet concentrate

9.17

90

16.28

+0.3mm omphacite c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com