Method for producing tough cathode with cupric sludge

A technology for cathode copper and copper sludge, which is applied in dewatering/drying/concentrating sludge treatment, improvement of process efficiency, photography process, etc., can solve the problems of copper salt containing many impurities and high process energy consumption, and achieve a simple process flow , mature technology, quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

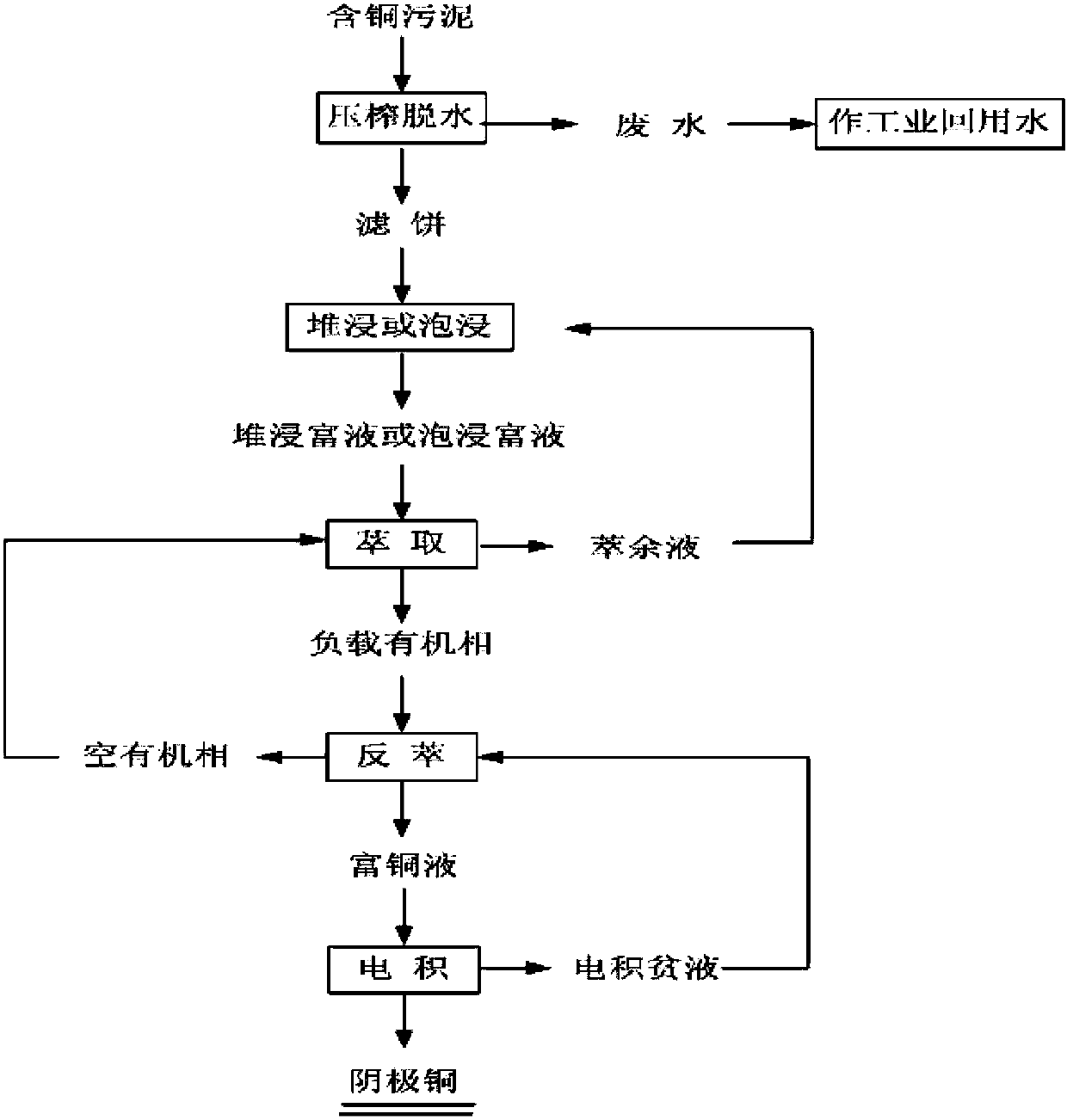

Method used

Image

Examples

Embodiment 1

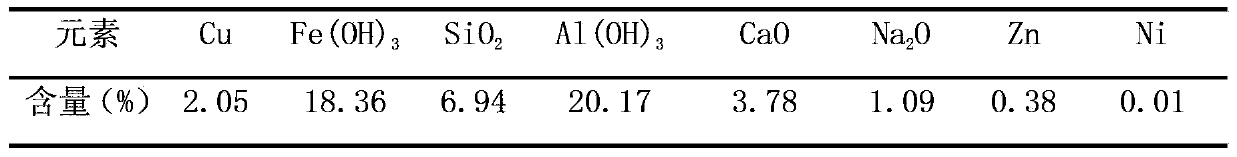

[0032] The copper sludge produced by the treatment of copper-containing acidic wastewater in a gold-copper mine mainly exists in the mixture of copper hydroxide, iron hydroxide, aluminum hydroxide, carbonate and other substances. In addition, there is a small amount of The analysis results of the main elements of the copper sludge are shown in Table 1.

[0033]Table 1 Analytical results of main elements in the sludge generated from the wastewater treatment of a gold-copper mine / % (dry basis)

[0034]

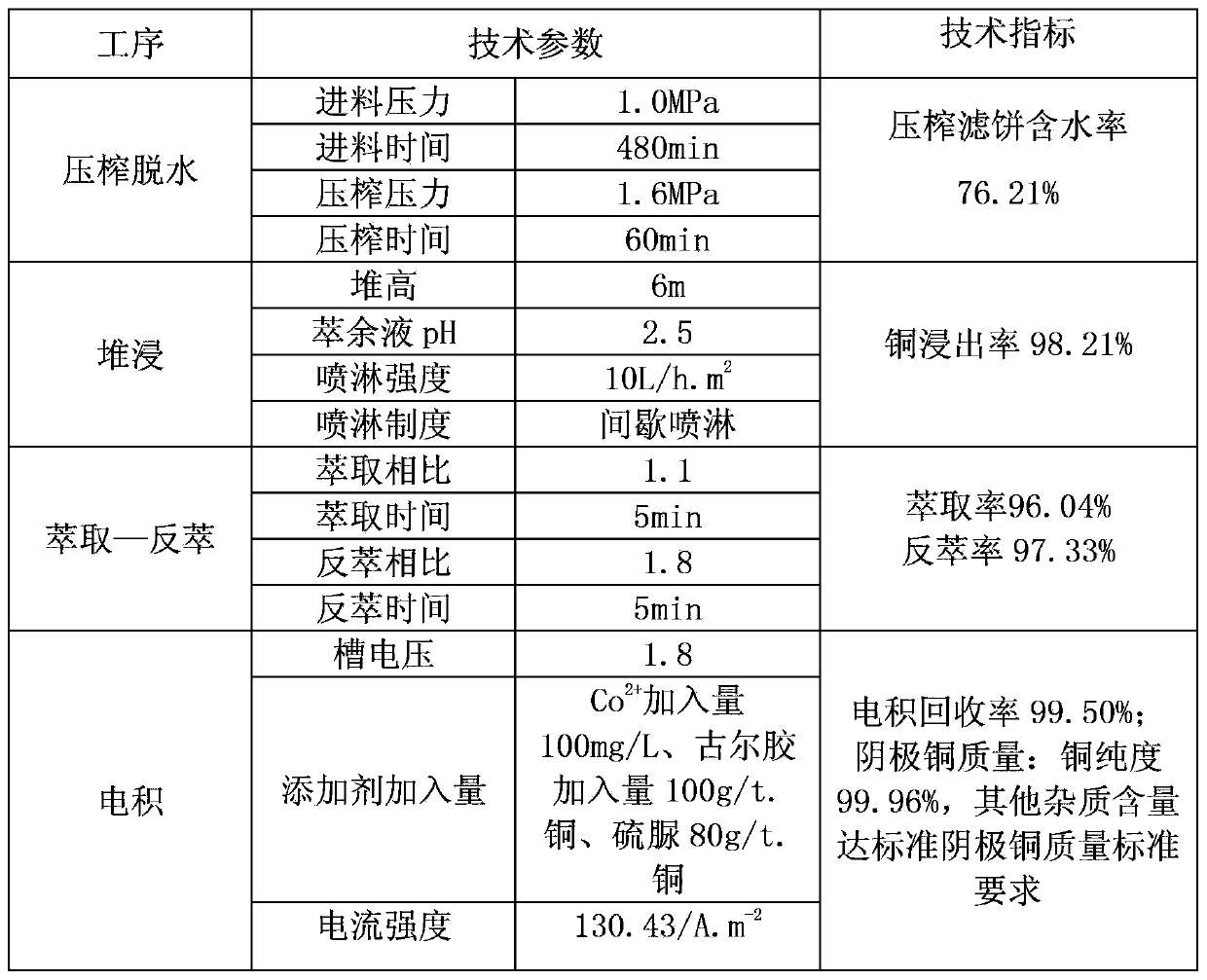

[0035] A method for producing cathode copper from copper-containing sludge comprises the following process steps in sequence:

[0036] The first step of pressing and dehydrating copper-containing sludge: the copper sludge with a moisture content of 96.75% produced by the treatment of copper-containing acidic wastewater from a gold-copper mine is fed and filtered by a slurry pump for 480 minutes, and the feed pressure filter is controlled at 1.0MPa. After the feed filtration ...

Embodiment 2

[0043] The copper sludge produced by the treatment of copper-containing acidic wastewater in an electroplating plant mainly exists in the mixture of copper hydroxide, iron hydroxide and other substances. The main element analysis results of the copper sludge are shown in Table 3:

[0044] Table 3 Analytical results of main elements of the sludge produced by wastewater treatment in an electroplating plant / % (dry basis)

[0045]

[0046] A method for producing cathode copper from copper-containing sludge comprises the following process steps in sequence:

[0047] The first step is dehydration of copper-containing sludge: the copper sludge with a moisture content of 94.63% produced by the treatment of copper-containing acidic wastewater in an electroplating plant is fed and filtered by a slurry pump for 120 minutes, and the feed filter is controlled at 0.6MPa. After the material is filtered, feed compressed air with a pressure of 1.2 MPa into the membrane filter plate to sque...

Embodiment 3

[0055] The copper sludge produced by the treatment of copper-containing acidic wastewater in a copper smelter is mainly a mixture of copper hydroxide, iron hydroxide and other substances. The main element analysis results of the copper sludge are shown in Table 5.

[0056] Table 5 Analysis results of main elements in the sludge produced by wastewater treatment in a copper smelter / % (dry basis)

[0057]

[0058] A method for producing cathode copper from copper-containing sludge comprises the following process steps in sequence:

[0059] The first step is press dehydration of copper-containing sludge: the copper sludge with a moisture content of 96.17% produced by the treatment of copper-containing acidic wastewater in a copper smelter is fed and filtered by a slurry pump for 240 minutes, and the feed filter is controlled at 0.8 MPa. After the feed is filtered, the compressed air with a pressure of 1.4 MPa is introduced into the membrane filter plate to press and dehydrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com