Spiral flow continuous centrifugal classifier

A centrifugal sorting and sorting technology, which is applied in the field of sorting machines, can solve the problems of thin sorting flow film, small sorting space, and difficulty in meeting the production requirements of the ore dressing industry, and achieve large thickness, strong ore storage and The effect of buffer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

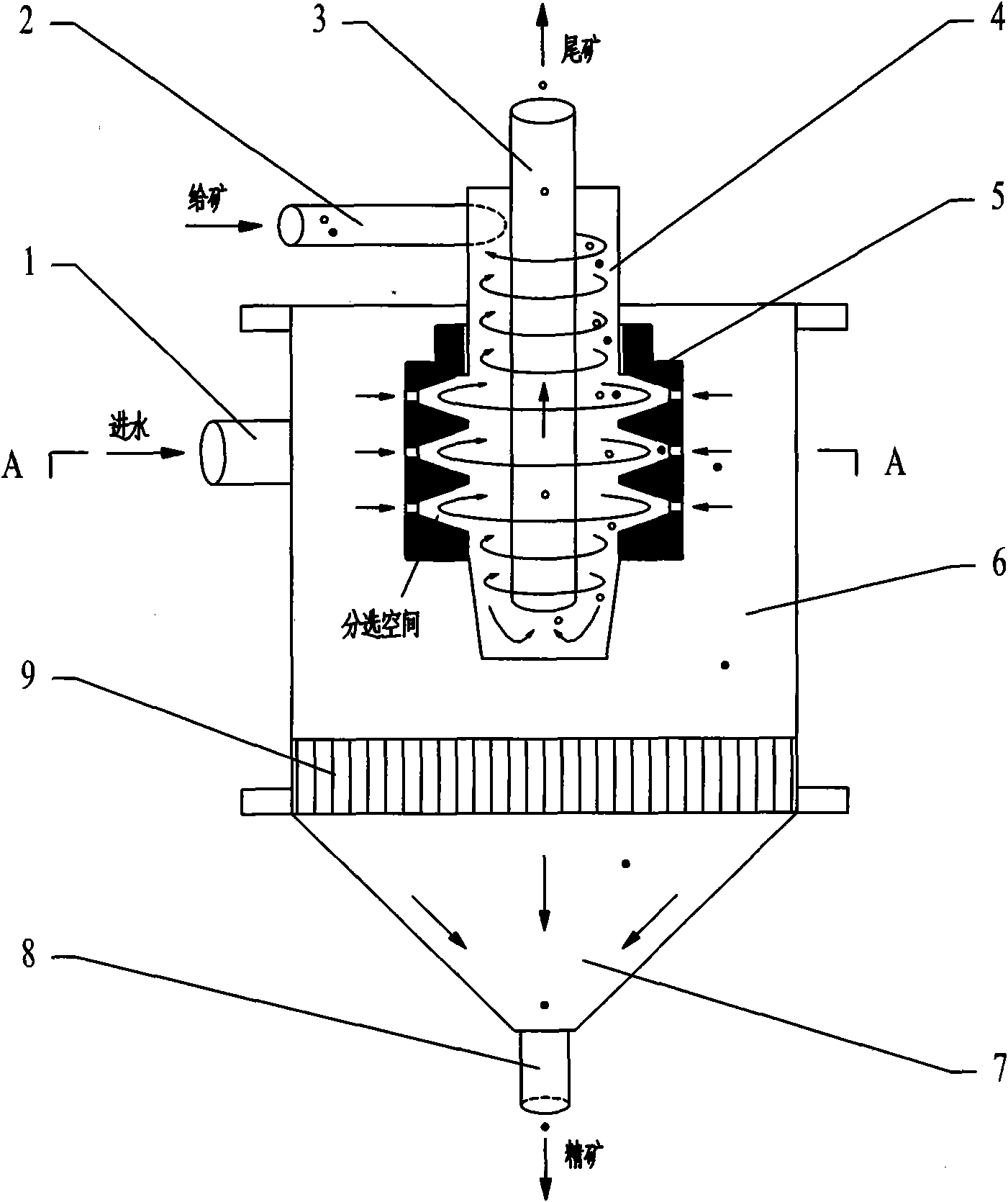

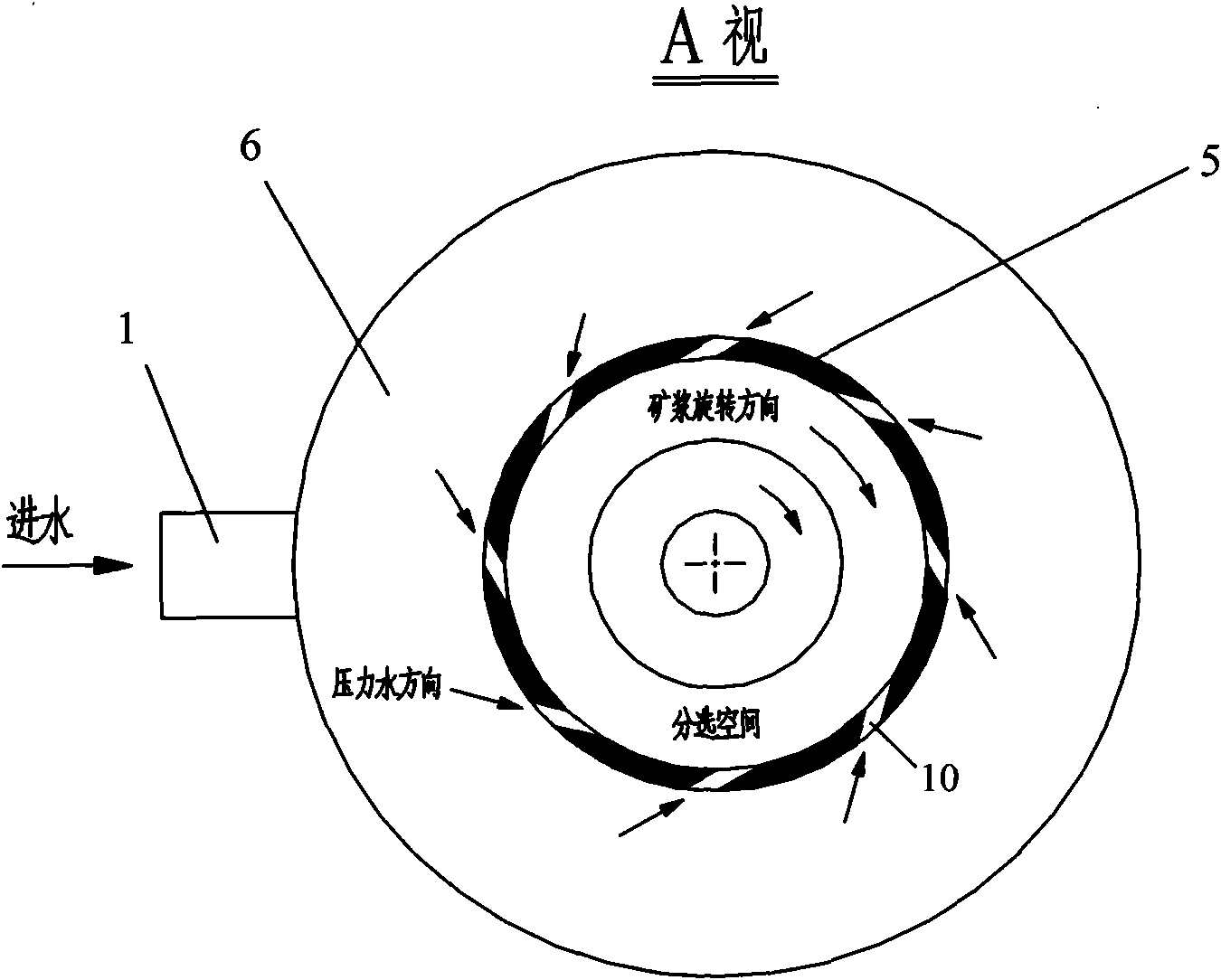

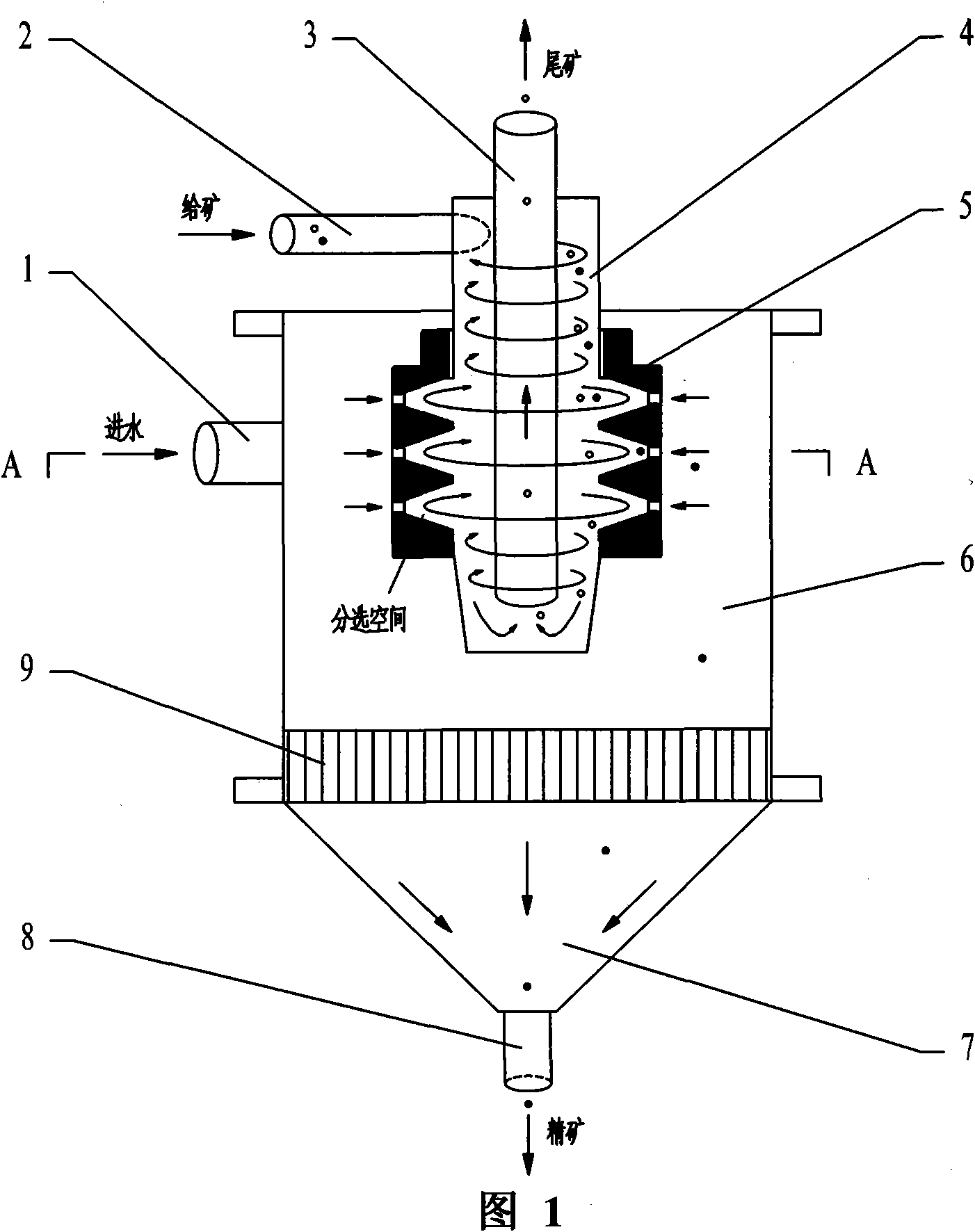

[0013] Such as figure 1 and 2 As shown, clean water enters the settling chamber 6 from the water inlet pipe 1 to form a certain water pressure, and the ore slurry is pumped tangentially into the swirl column 4 from the feed pipe 2, and its pressure energy is converted into rotational kinetic energy to establish a centrifugal force field. During the rotation and downward movement of the slurry in the swirl column 4, due to the different centrifugal forces, the ore particles are stratified according to the density difference. The heavy minerals are mainly distributed outside the swirl column 4, and the light ore particles are mainly distributed in the swirl column 4. On the inner side, this stratification process is mainly pre-sorted according to the cyclone principle. The pre-sorted pulp swirls into the conical ring groove sorting space where the sorting cone 5 is located for sorting, in which the heavy minerals are subjected to strong centrifugal force and are discharged from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com