Beneficiation method for coal series kleit

A technology of coal-based kaolin and ore dressing method, which is applied to centrifuges with rotating drums, centrifuges, etc., can solve problems such as production stoppage, slow sales, poor grade of raw ore, etc., achieve large processing capacity, improve purity, and reduce iron and titanium The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] 50Kg of coal series kaolin powder in Yichang area (mechanically ground to 700-800 mesh), water and sodium hexametasulfate in a mass ratio of 1:5:0.004 to make a slurry, after strong stirring, with a pressure of 0.6MPa Enter a hydrocyclone with a pipe diameter of 25 mm for classification. After 10 minutes, the classification is completed, and the underflow waste ore and overflow concentrate pulp are obtained, which are dehydrated and dried respectively. The test data are shown in Table 1.

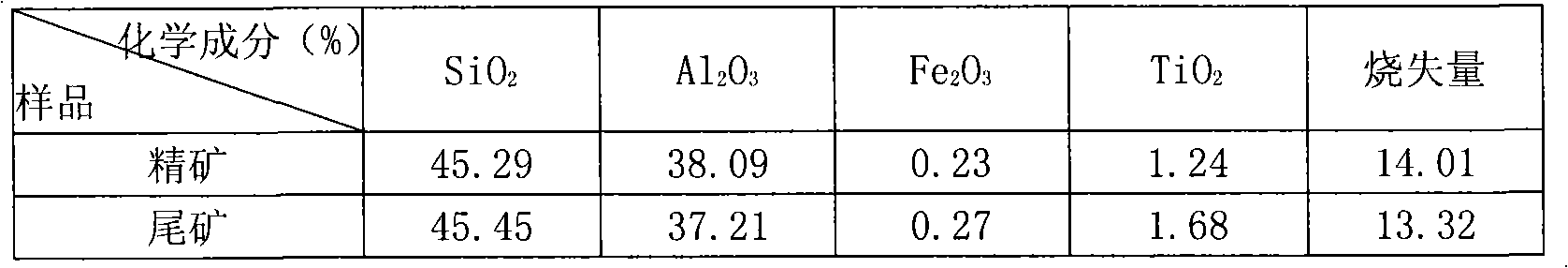

[0038] Table 1 Example 1 test results

[0039]

example 2

[0041] 50Kg of coal series kaolin powder (700-800 mesh) in Yichang area, water and sodium hexametasulfate are mixed into a slurry with a mass ratio of 1:3.3:0.004, and after strong stirring, enter the pipe with a pressure of 0.6MPa. The 25mm hydrocyclone is used for classification. After 10 minutes, the classification is completed, and the underflow waste ore and overflow concentrate pulp are obtained, which are dehydrated and dried respectively. The test data are shown in Table 2.

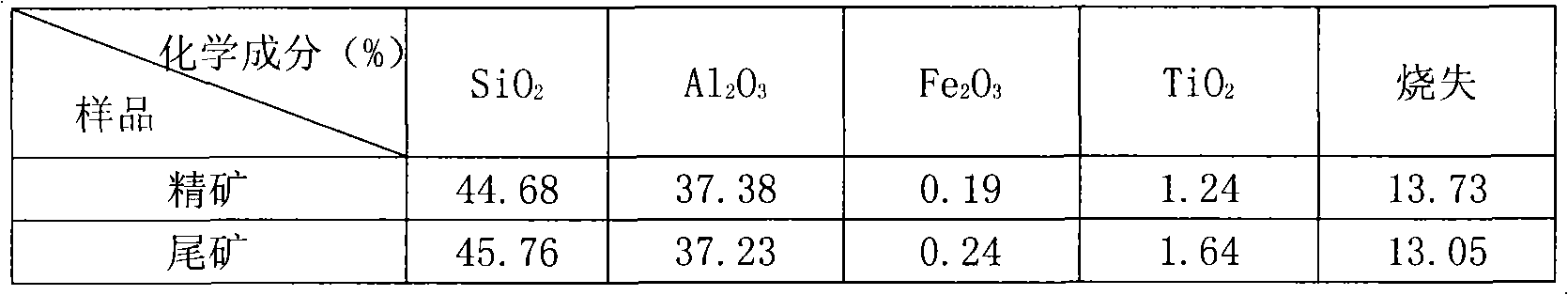

[0042] Table 2 Example 2 Test Results

[0043]

example 3

[0045] 50Kg of coal series kaolin powder (700-800 mesh) in Yichang area, water and sodium hexametasulfate are mixed into a slurry with a mass ratio of 1:2.5:0.004, and after strong stirring, enter the pipe with a pressure of 0.6MPa. The 25mm hydrocyclone was used for classification. After a few minutes, the classification was completed, and the underflow waste ore and overflow concentrate pulp were obtained, which were dehydrated and dried respectively. The test data are shown in Table 3.

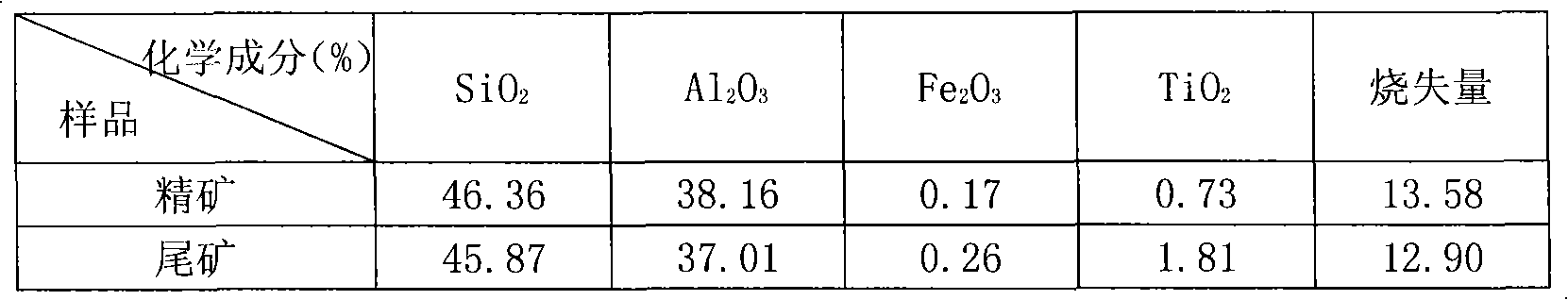

[0046] Table 3 Example 3 Test Results

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com