Mineral processing technology capable of effectively separating tantalum, tin and lepidomelane

A technology of iron lepidolite and process, which is applied in the field of beneficiation process to achieve the effect of improving utilization rate, simplifying process and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

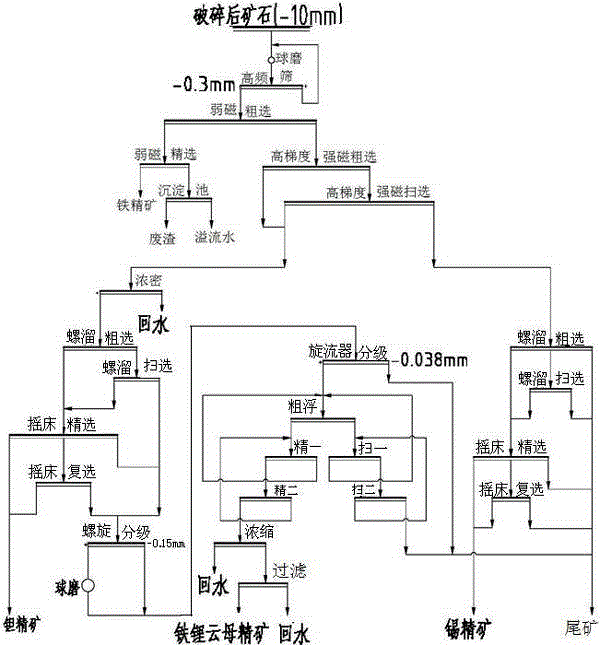

[0012] The raw ore is crushed to -10mm through three stages and one closed circuit, and the crushed ore products enter the grinding and heavy section. The first stage of grinding is composed of a ball mill and a high-frequency vibrating fine screen to form a closed circuit. The particle size of the grinding product is -0.3mm. Iron and weak magnetic concentrates are selected by a weak magnetic separator to obtain high-grade iron concentrates, and the weak magnetic tailings are discarded as waste residues; the materials after iron removal are roughly swept by a high-gradient strong magnetic separator, and the magnetic minerals are concentrated After concentrating by machine, the tantalum concentrate can be obtained by re-election by spiral chute and shaker; after the gravity-selected tailings are classified by the spiral classifier, they are returned to the sand for regrinding, and the grinding particle size is -0.15mm. Spiral classifier overflow and regrind The ore discharge is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com