Centrifugal classifier

A technology of centrifugal classification and separation hood, applied in centrifuges, separation of sediments by centrifugal force, separation methods, etc., can solve the problems of unstable flow, uncertain classification particle size, low classification efficiency, etc., to improve classification efficiency, reduce The effect of mixed thickness and high classification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

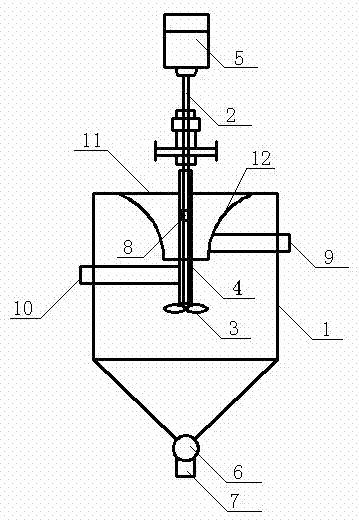

[0022] Such as figure 1 As shown in the structural diagram of this centrifugal classifier, it at least includes a body 1, a feed nozzle 10, a discharge pipe 9, and a sand discharge port 7, a discharger 6, an impeller 3, an air inlet 8, a cover 12, and a motor 5. End cap 11 and rotating shaft 2.

[0023] The main body 1 is a hollow cavity structure formed by connecting two parts of a cylindrical cavity and a conical cavity, wherein the lower end of the cylindrical cavity is fixedly connected with the large end surface of the conical cavity; the upper part of the main body 1 passes through the end The cover 11 is sealed, the upper end of the hollow cavity inside the body 1 is fixed with a separation cover 12, the separation cover 12 is connected with one end of the discharge pipe 9, the other end of the discharge pipe 9 extends outside the body 1, and the side of the body 1 is also fixed with Feed pipe 10; motor 5 is fixed on the upper part of body 1, and motor 5 is connected w...

Embodiment 2

[0027] The body 1 in the above embodiment is a vertical structure, and the feeding pipe 10 is fixed along the involute-tangential direction of the upper end of the side of the body 1, and the horizontal height of the upper and lower edges of the feeding port 10 is not higher than the separation cover 12. The horizontal height of the upper and lower edges is in the middle of the separation cover 12 .

[0028] The form that the feed pipe 10 is arranged along the involute-tangential direction needs to pump the mixed material into the body 1 with a sand pump. When the capacity of the material is insufficient, it is thrown up by the impeller 3 to replenish energy and be classified again.

Embodiment 3

[0030] The feed pipe 10 in Embodiment 1 can also extend into the body 1 through the side wall of the body 1 , and finally communicate with the sleeve 4 outside the rotating shaft 2 . Driven by the motor 5 to rotate the impeller 3, the slurry can enter the sleeve 4 under the feed pressure of less than 0.06Mpa, and rotate at a high speed in the cylindrical column of the body 1 under the rotation of the impeller 3 to realize the slurry (or gas) ) classification, while the fine-grained grade, water, and gas can enter the body 1 through the air inlet 8 after entering the sleeve 4 .

[0031] Since the centrifugal classifier operates under a relatively small pressure (0.01 mpa< p<0.16mpa), or self-priming without pressure, the swirl speed is low, thereby reducing the loss and energy consumption loss. While improving the classification efficiency, it also achieves the purpose of energy saving. There is no internal circulation, no pulp "short circuit", and the operation is stable. Su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com