Upward-spraying mine well exhaust air heat recovery device and design method thereof

A technology of heat recovery device and design method, which is applied to lighting and heating equipment, direct contact heat exchangers, heat pumps, etc., can solve the problems of large wind blowing water loss, large power consumption of circulating water pumps, and short contact time, etc., to achieve Increase the heat exchange distance and heat exchange time, improve heat recovery efficiency, and increase the effect of heat exchange time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

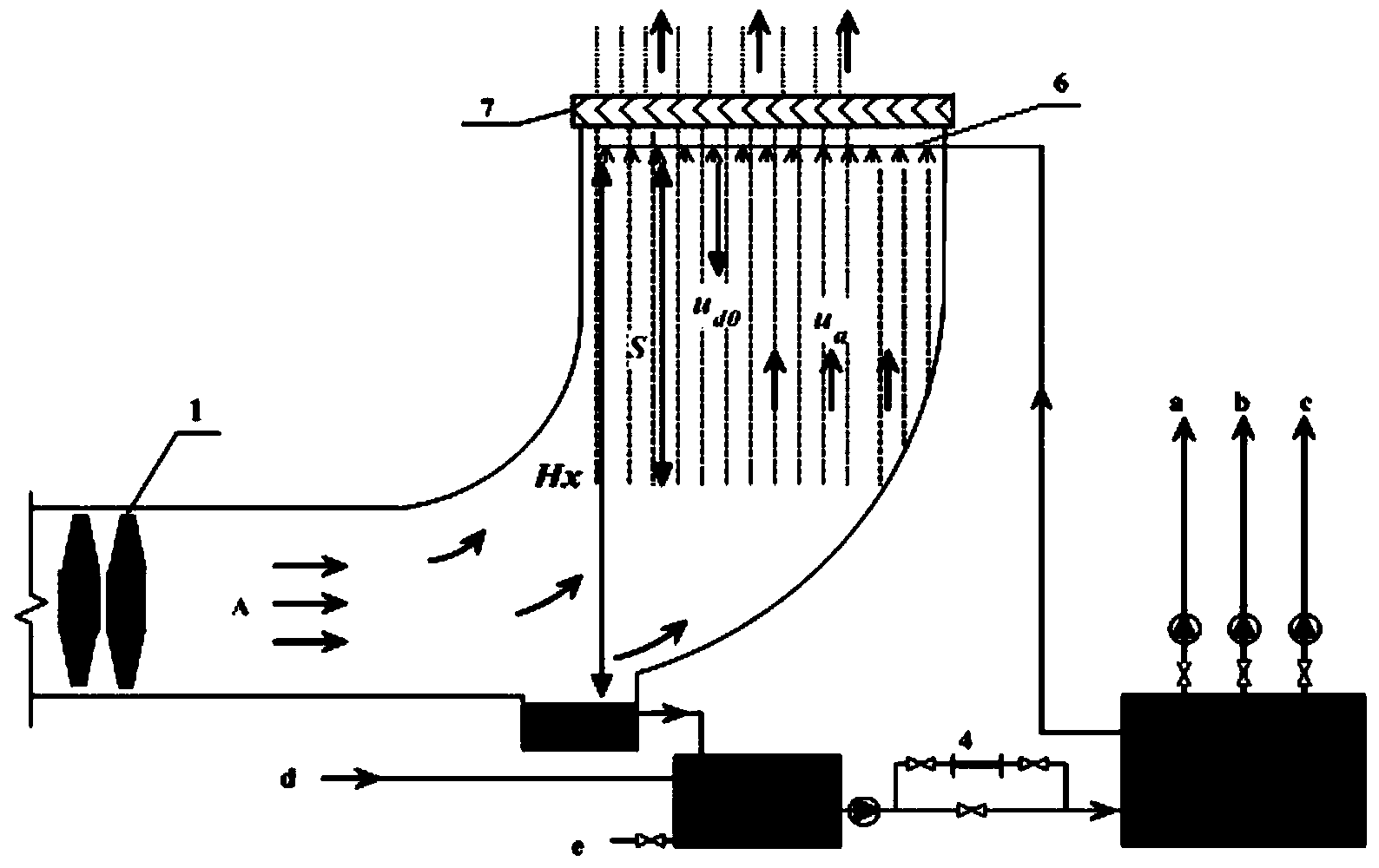

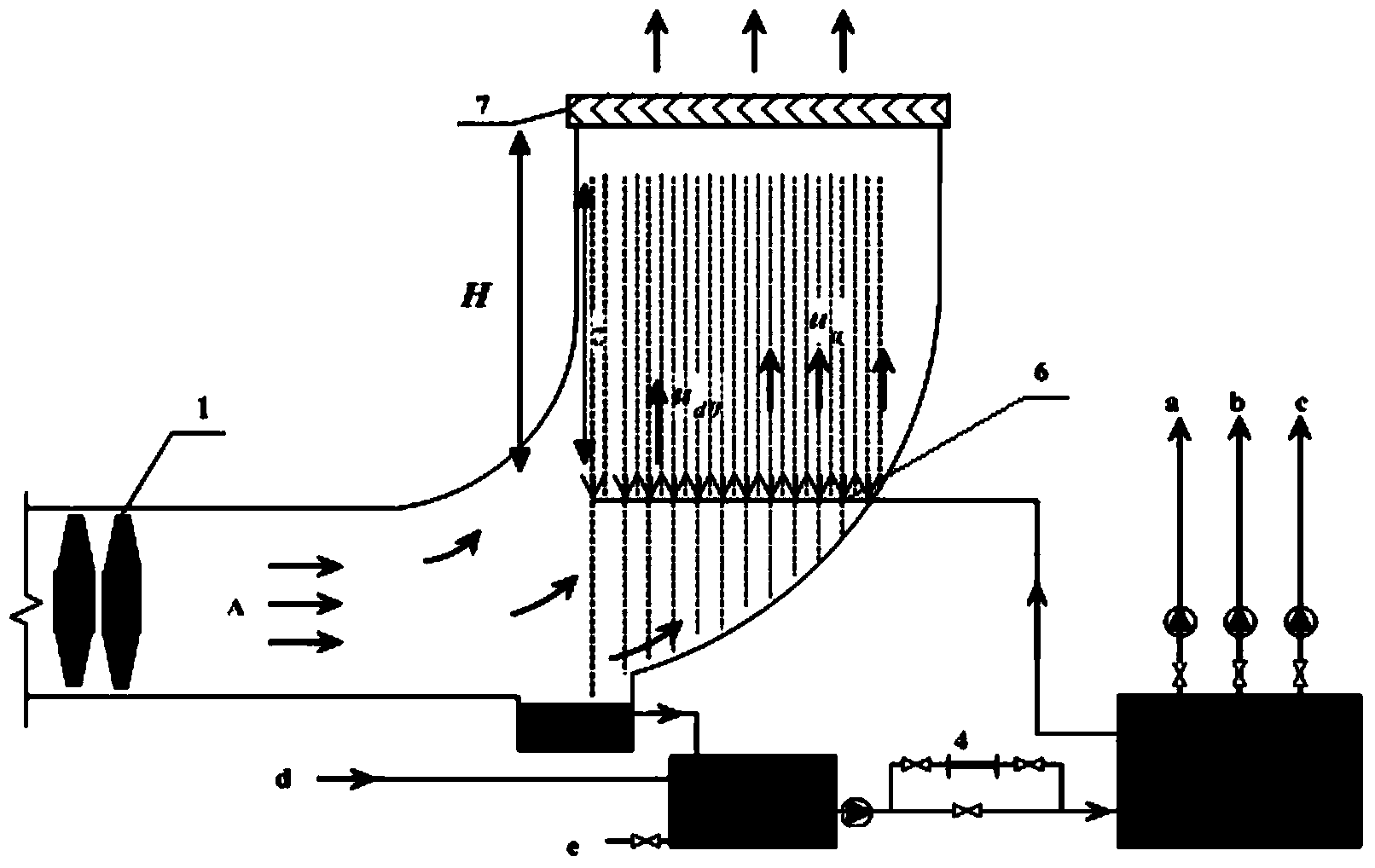

[0082] see figure 1 , which is a schematic diagram of the principle structure of a common mine exhaust heat recovery device, in figure 1 Among them, 1 is the main ventilator, 2 is the sump, 3 is the sedimentation tank, 4 is the water processor, 5 is the heat pump unit, 6 is the pipe row and nozzle, 7 is the water baffle, A indicates the mine return air, a interface Connect the wellbore antifreeze water pipe, the b interface connects the hot water pipe for bathing, the c interface connects the air conditioning water pipe, the d interface connects the waste water pipe of the bathroom, and the e interface connects the sewage device. Hx is the installation height of the nozzle, S is the maximum drop drop height, u a is the face velocity of the air, u d0 is the initial velocity of the droplet. Such as figure 1 As shown, the spraying facilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com