Method for forming blade material particles special for wire-electrode cutting of semiconductor material and ultra-hard material

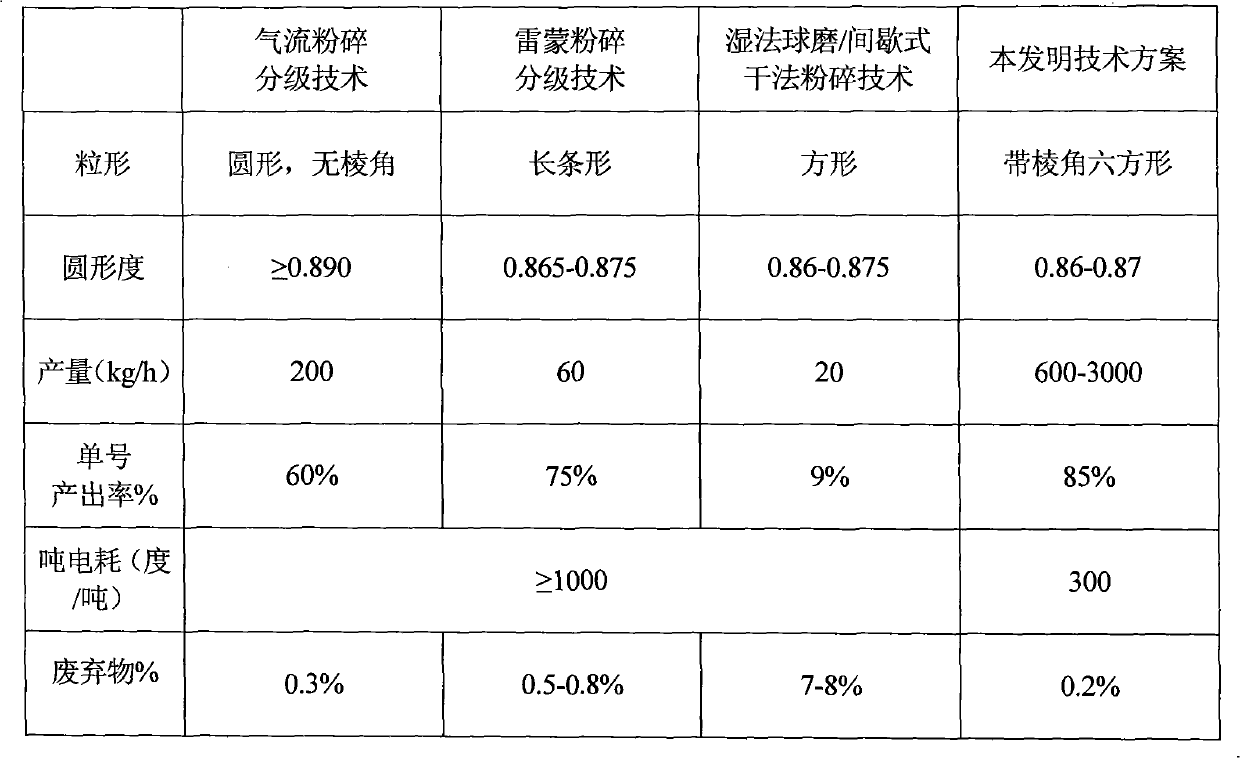

A superhard material and particle forming technology, applied in the direction of grain processing, etc., can solve the problem of low (wet ball mill only about 30kg/h, jet mill can only reach about 200kg/h, waste water, waste gas and solid Problems such as waste polluting the environment and low output rate can achieve the effect of maintaining good product crystallization, good anti-breaking performance, and increasing the yield of slicing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

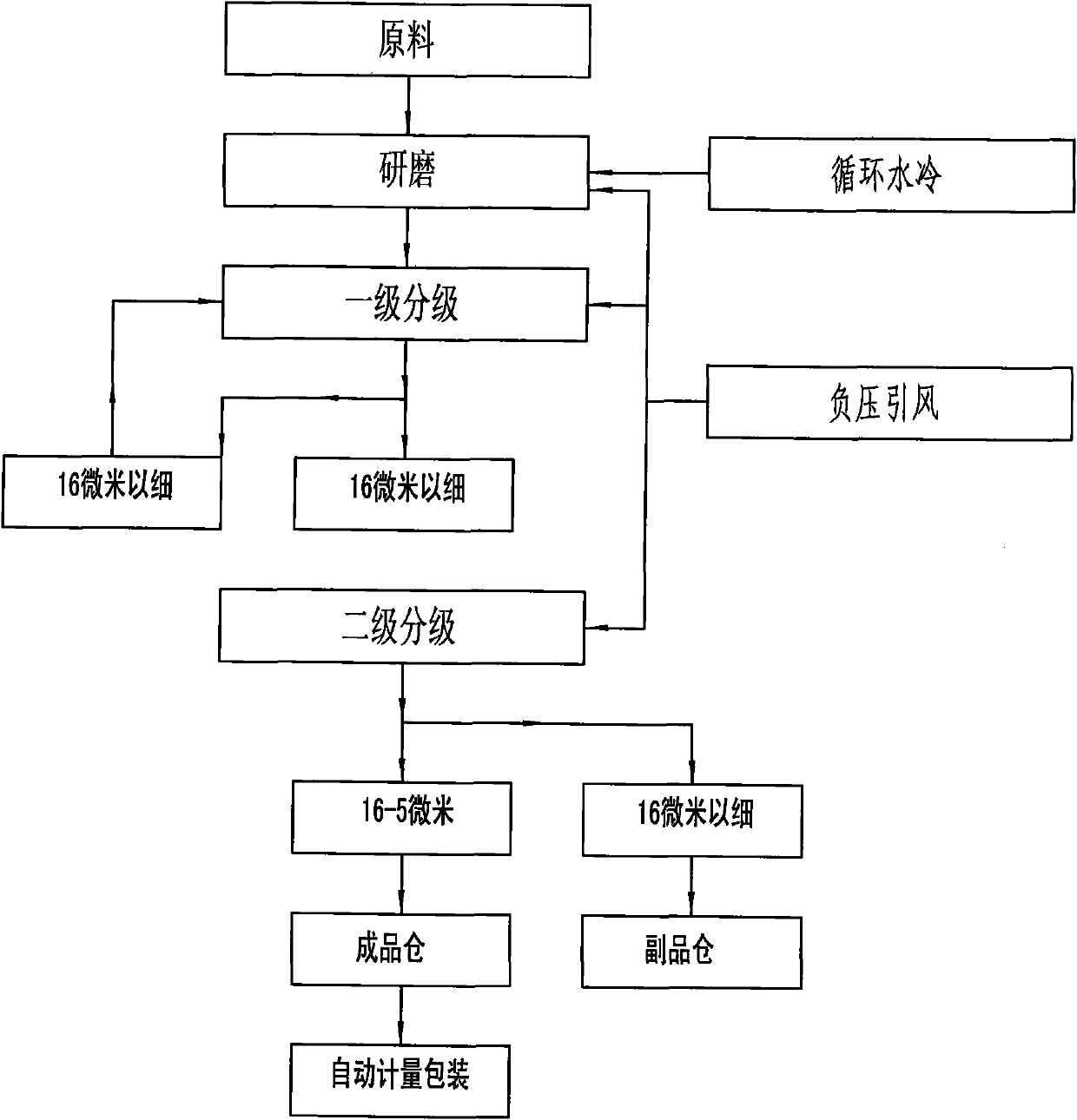

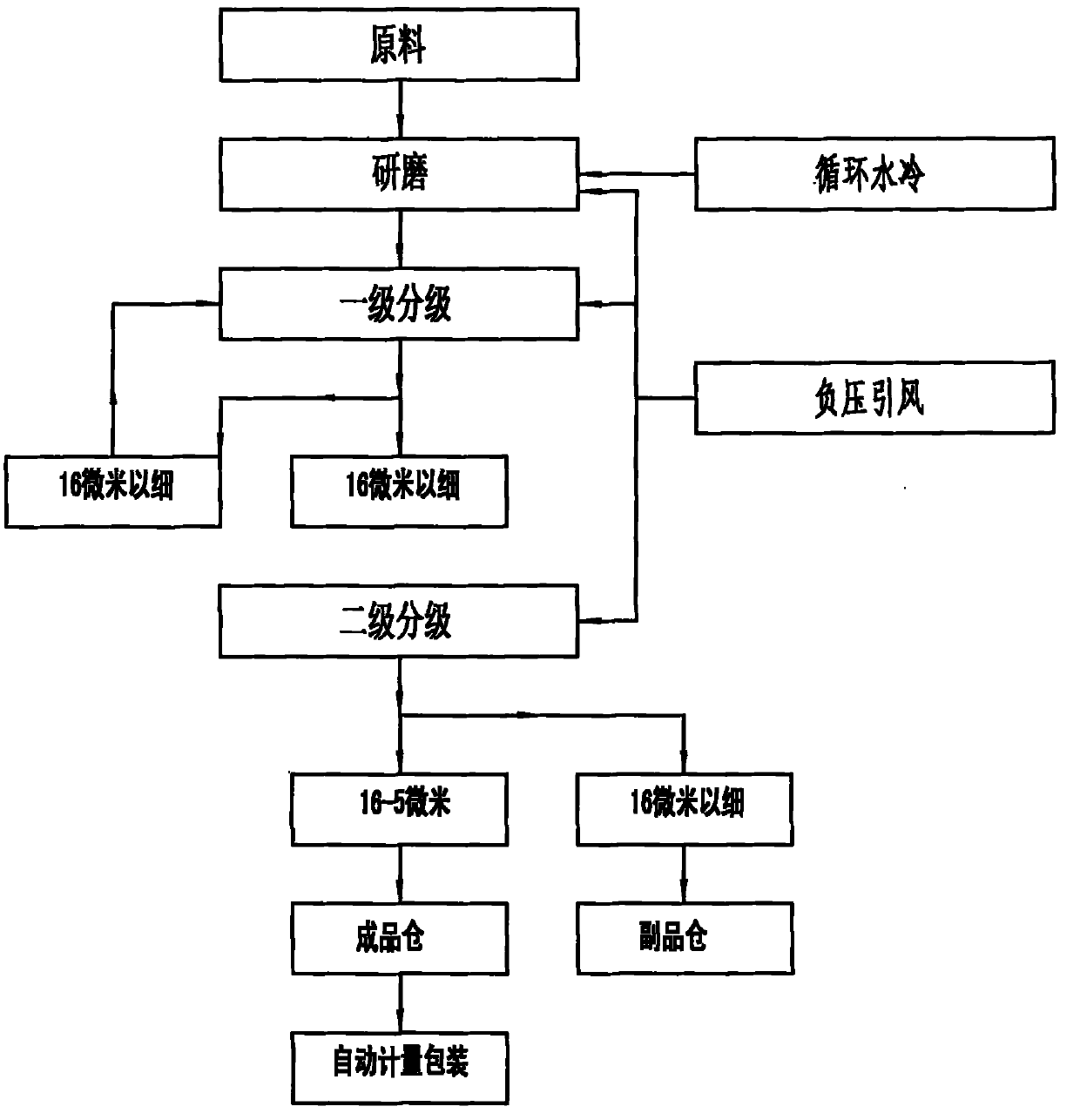

[0025] As shown in the figure, the method for forming special blade particles for wire cutting of semiconductor materials and superhard materials according to the present invention comprises the following steps:

[0026] Step 1: Select silicon carbide (microhardness HV≥3000, structural purity 95%, toughness ≥70%) with Mohs hardness ≥ 9.3 and crystal form of 6H-SiC or Mohs hardness ≥ 9.9-10, Composite synthetic diamond (toughness ≥ 90%) superhard material of crystal type 6H-SiC is used as raw material;

[0027] Step 2: Send the raw materials into the air-swept grinder through the screw feeder for grinding. During the grinding, the computer will automatically measure and feed the materials, and the feeding speed will be controlled from 700 to 3500kg / h. The grinding medium gradation is Φ50: Φ40: Φ30 =0.4~0.6:1:0.5~0.7, quantity 11000~40000Kg: Monitor the change of grinding current through the man-machine interface, when the current is less than 10~15% of the rated current of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com