System for preparing straw micro powder

A technology of straw and micropowder, which is applied in the direction of separating solids from solids with airflow, solid separation, and grain treatment, etc. problems, achieve the effect of shortening the production cycle, increasing the output per machine hour, and reducing over-grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

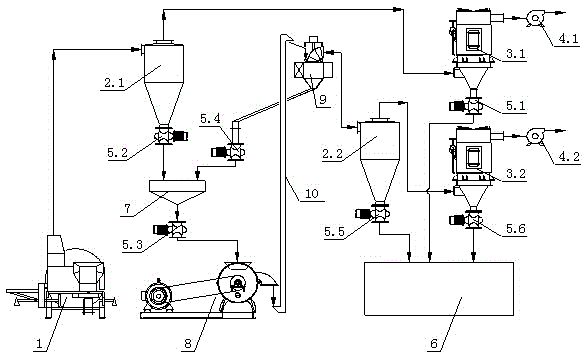

[0049] Below in conjunction with accompanying drawing, the present invention will be further described:

[0050] like figure 1Shown is a schematic diagram of the system principle of the present invention: In this embodiment, the crop straw we use as the pre-crushed raw material is a 15-20 mm long section, and it is dried at the same time so that the moisture content is preferably less than 10% , after pre-crushing, the raw material of straw powder with a D90 of about 800um fineness is obtained. There may be a small amount of small gravel mixed in the straw, which will be discharged to the bottom of the straw pre-shredder during the pre-crushing process, and discharged through the slag discharge port at the bottom.

[0051] The straw particles crushed by the straw pre-crusher are pneumatically transported to the cyclone separator under the suction of the fan for collection, and a very small amount of particles (particle size ≤ 25um) pass through the exhaust port at the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com