Highly dispersible spherical nano-silver powder and preparation method thereof

A spherical nano-silver, high-dispersity technology, applied in the field of nano-silver powder, can solve the problems of poor product dimensional stability, large size of spherical silver powder, wide particle size distribution, etc., and achieve the effects of low cost, easy addition and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of highly dispersed spherical nano-silver powder, comprising the steps of:

[0027] (1) Mix 400g PEG400 and 100g PEG2000 with 18g deionized water and stir well.

[0028] (2) Weigh 425mgAgNO 3 and 100mg of glucose solids were added to the solution obtained in step (1), fully dissolved, and stirred evenly.

[0029] (3) The reaction temperature is 70° C., and the reaction time is 3 hours. The reaction product is centrifuged at 5000 rpm, filtered, and washed three times with distilled water to obtain silver nanoparticles.

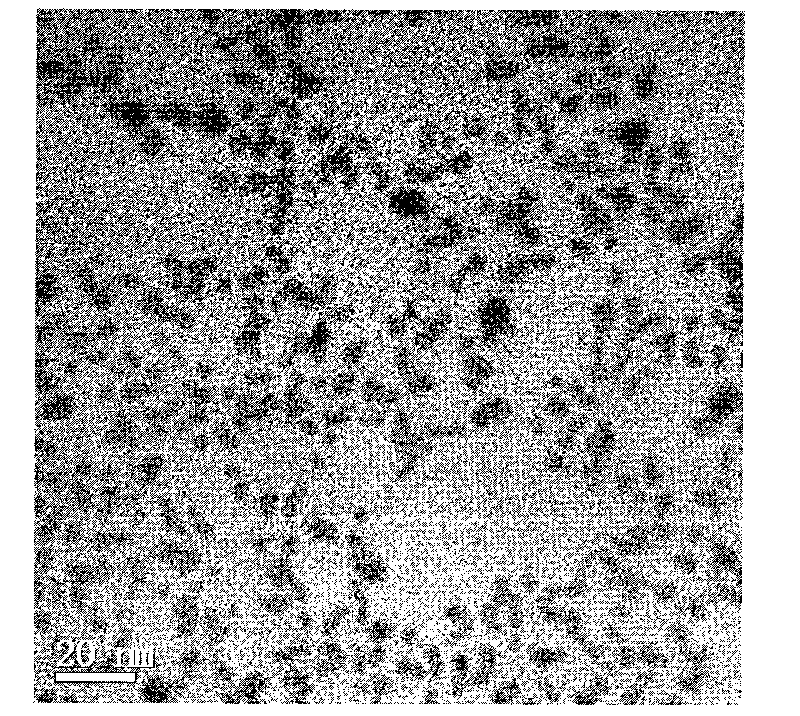

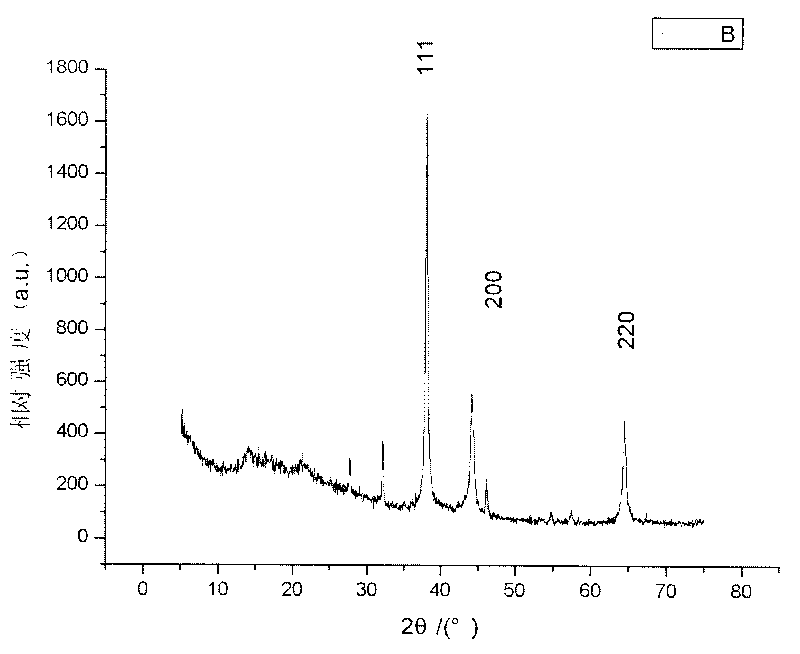

[0030] The transmission electron microscope picture of gained nano-silver prepared in this embodiment is as follows figure 1 As shown, it can be seen from the figure that the nano-silver is spherical, the particle size is about 3-20nm, and belongs to the nanoscale. The obtained spherical nano-silver powder has high dispersion and no agglomeration between particles. The XRD figure of present embodiment gained nano-silver, as figu...

Embodiment 2

[0032] A preparation method of highly dispersed spherical nano-silver powder, comprising the steps of:

[0033] (1) Mix 600g PEG600 and 50g PEG1000 with 18g deionized water and stir well.

[0034] (2) Weigh 1200mgAgNO 3 and 100mg of glucose solids, added to the PEG solution, fully dissolved, and stirred evenly.

[0035] (3) The reaction temperature is 60° C., and the reaction time is 10 h. The reaction product is centrifuged at 8000 rpm, filtered, and washed three times with distilled water to obtain silver nanoparticles.

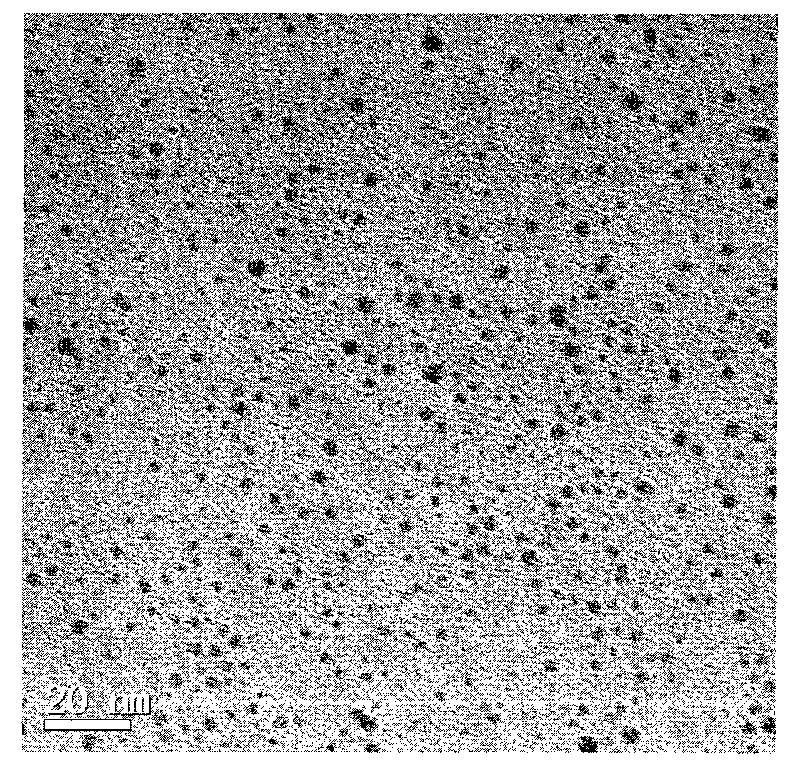

[0036] The transmission electron microscope picture of gained nano-silver prepared in this embodiment is as follows image 3 As shown, it can be seen from the figure that the nano-silver is spherical, with a particle size of about 3-10 nm, and no agglomerated particles. The XRD pattern of the nano-silver obtained in the present embodiment is basically the same as figure 2 shown.

Embodiment 3

[0038] A preparation method of highly dispersed spherical nano-silver powder, comprising the steps of:

[0039] (1) Mix 400g PEG400 and 100g PEG600 with 90g deionized water and stir well.

[0040] (2) Weigh 2000mgAgNO 3 and 100mg of glucose solids were added to the solution obtained in step (1), fully dissolved, and stirred evenly.

[0041] (3) The reaction temperature is 70° C., and the reaction time is 2 hours. The reaction product is centrifuged at 7000 rpm, filtered, and washed three times with distilled water to obtain silver nanoparticles.

[0042] The transmission electron microscope picture of gained nano-silver prepared in this embodiment is as follows Figure 4 As shown, it can be seen from the figure that the nano-silver is spherical, the particle size is about 3-20nm, and there is no agglomerated particle. The XRD pattern of the nano-silver obtained in the present embodiment is basically the same as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com