Mechanical engineering powder waste treatment and recovery system

A technology of mechanical engineering and recycling system, applied in the post-processing of mixtures, mixers, presses, etc., can solve the problems affecting the service life of screening machines, air pollution, air pollution, etc., and achieve a simple structure, convenient collection, and convenient transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

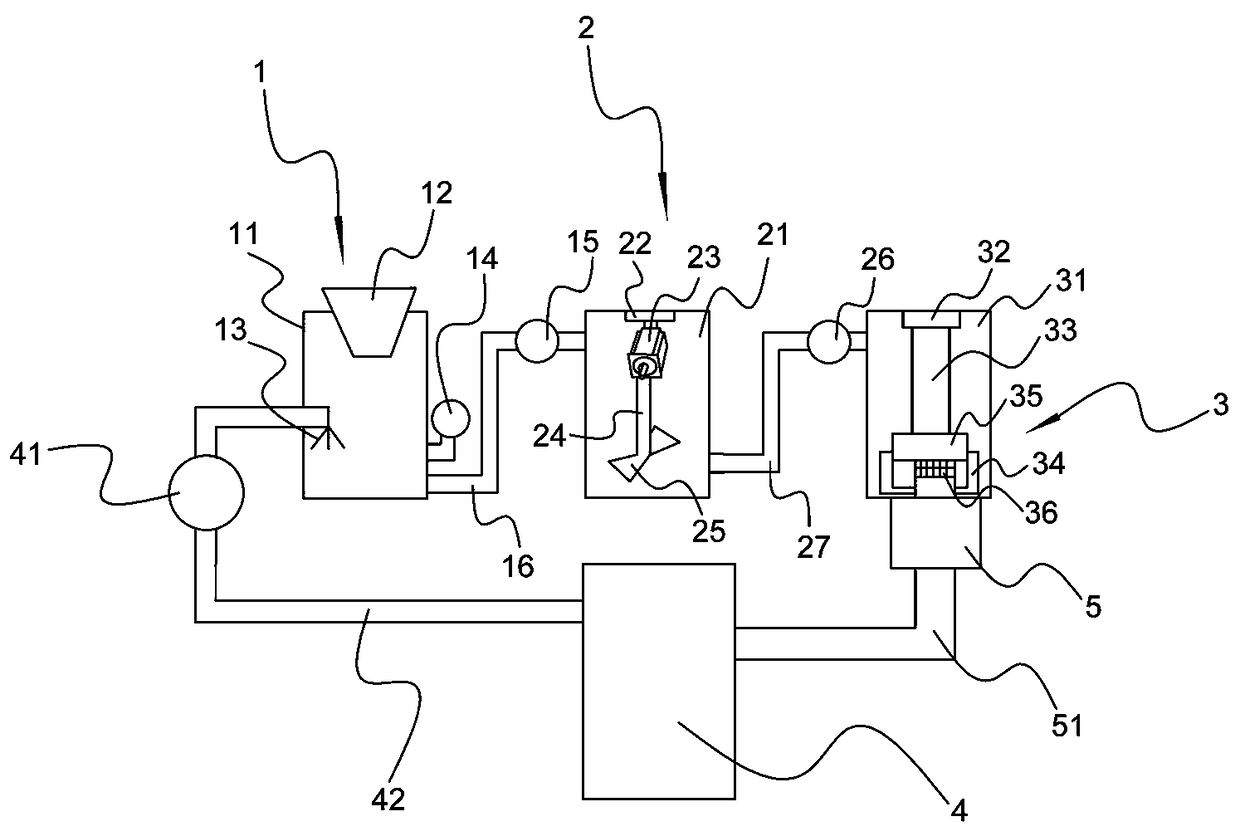

[0019] see figure 1 , the mechanical engineering powder waste treatment and recycling system in this embodiment includes a liquefaction device 1 for dissolving powder waste into water to form a first powder liquid, and for stirring the first powder liquid to form a second powder liquid. The stirring device 2 for powder liquid, the first diaphragm pump 15 for extracting the first powder liquid in the liquefaction device 1, the first diaphragm pump 15 for receiving the first powder liquid extracted by the first diaphragm pump 15 and transporting it to the stirring device 2 The conveying pipe 16, the pressing device 3 used to press the second powder liquid to form a powder plate, the second diaphragm pump 26 used to extract t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com