Residual stress peak position positioning method based on acoustic emission technology

An acoustic emission technology and residual stress technology, applied in the field of non-destructive testing, to achieve the effect of good acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] With reference to accompanying drawing, further illustrate the present invention:

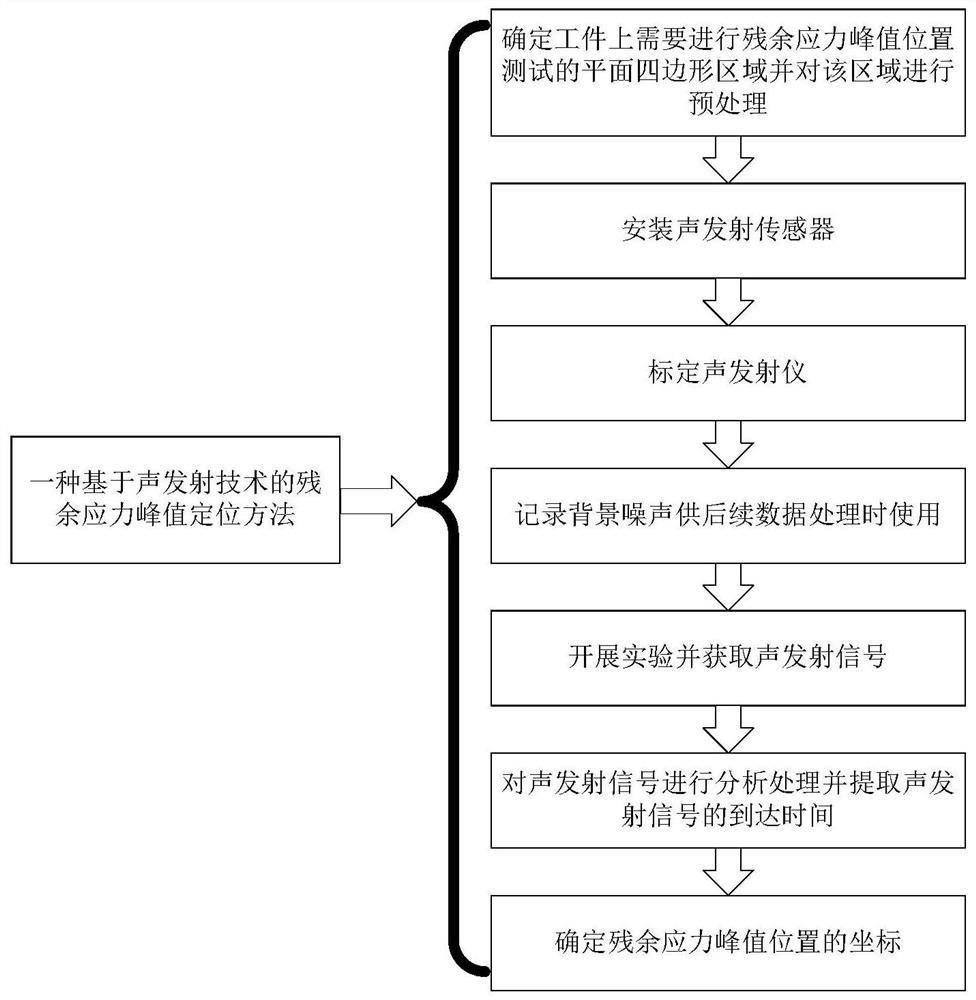

[0074] The location method of residual stress peak position based on acoustic emission technology includes the following steps:

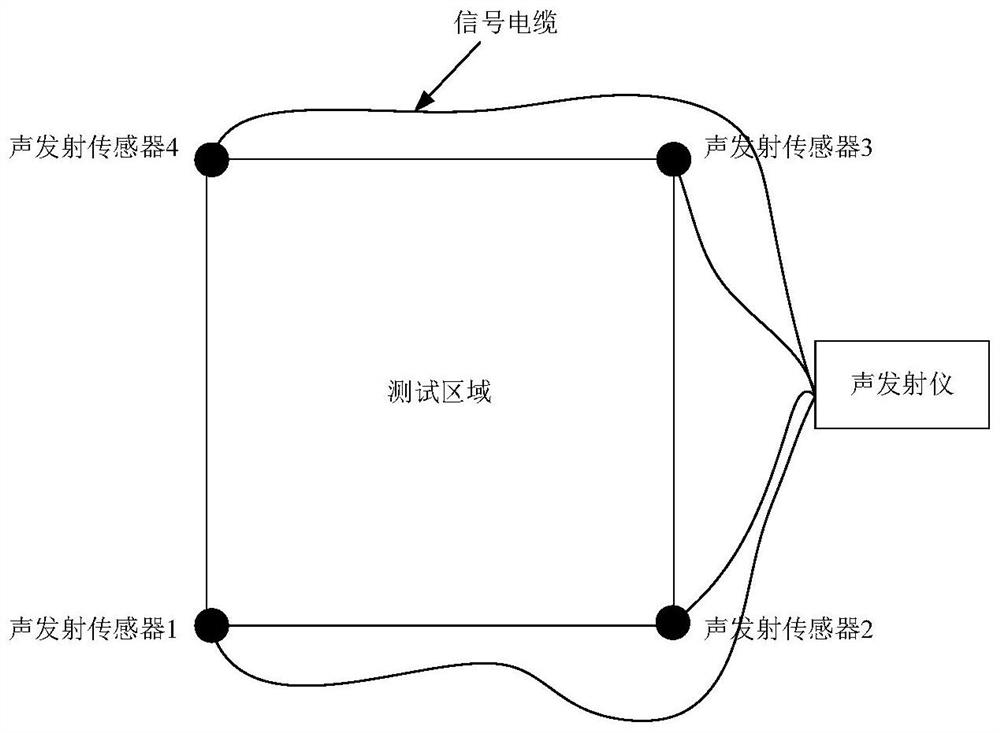

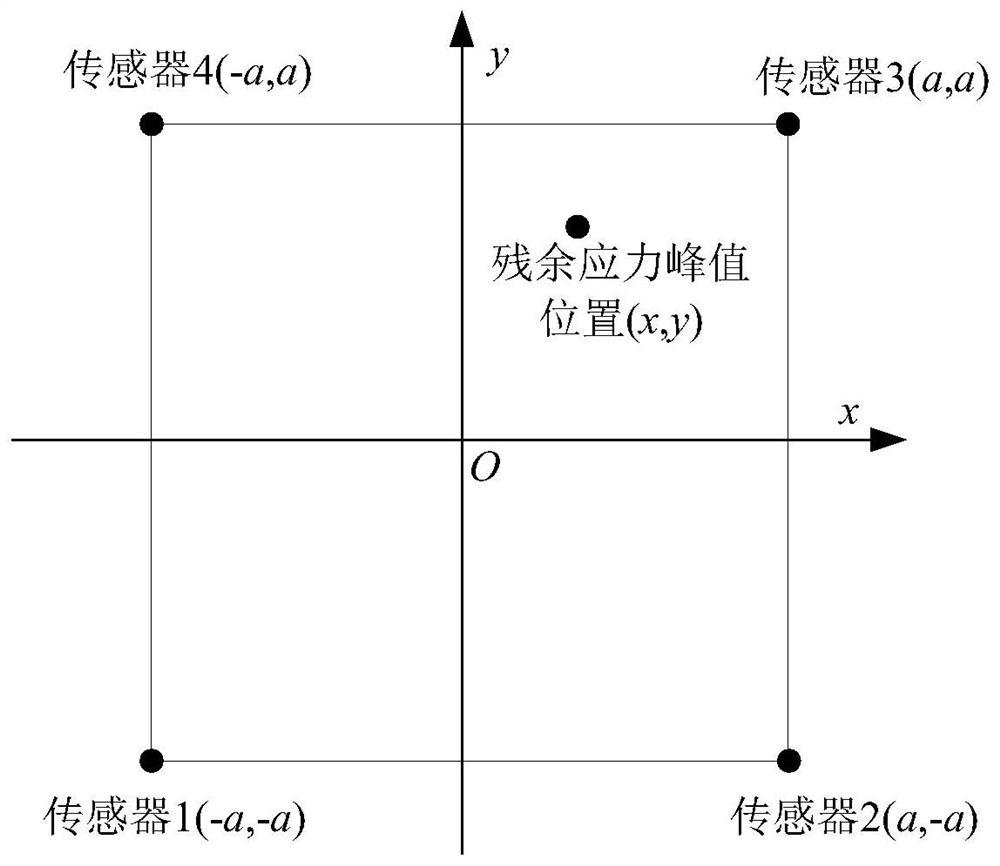

[0075] (1) Determine the planar quadrilateral area on the workpiece that needs to be tested for the peak position of residual stress: firstly, simulate the machining process of the workpiece through finite element numerical simulation technology, obtain the distribution state of the surface residual stress of the workpiece, and obtain the area where the larger residual stress is located , and preliminarily obtain the peak position of the residual stress; secondly, determine a plane quadrilateral area including the preliminarily obtained peak position of the residual stress, which is the test area; then polish the surface of the test area to reduce the surface roughness of the workpiece and ensure that the acoustic emission The sensor can be closely attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com