Sedimentation tank easy to clean

A sedimentation tank and easy-to-clean technology, applied in the field of sedimentation tanks, can solve the problems of rough concrete surface, unfavorable sedimentation sludge collection and cleaning, etc., and achieve the effect of easier collection, easier cleaning, and convenient dredging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

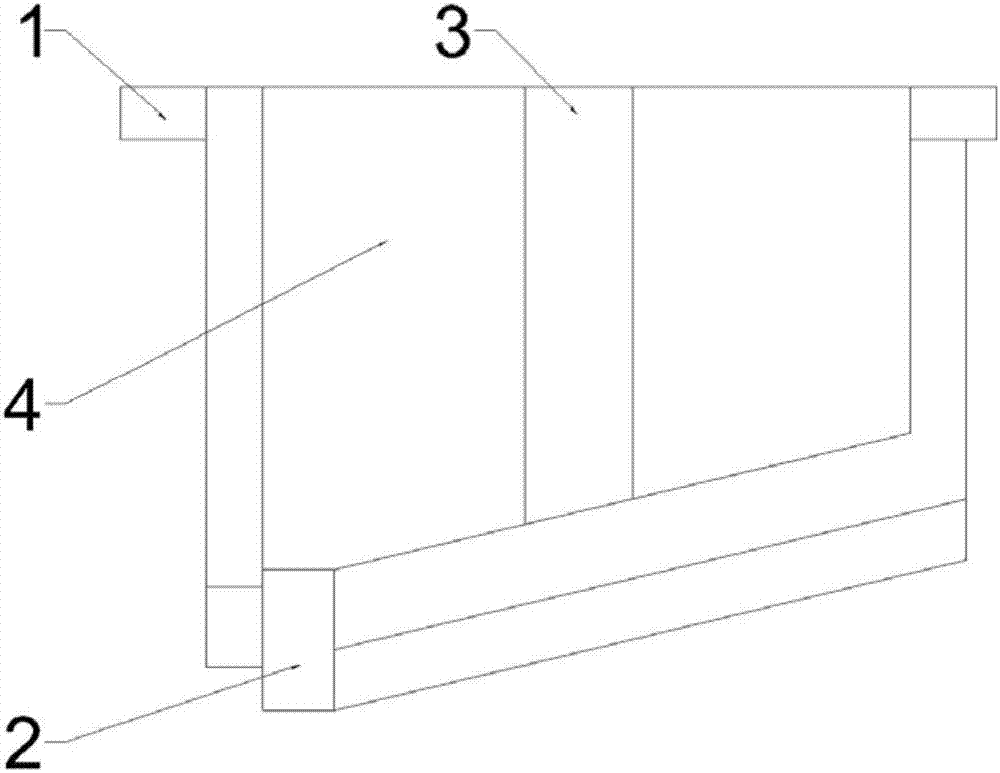

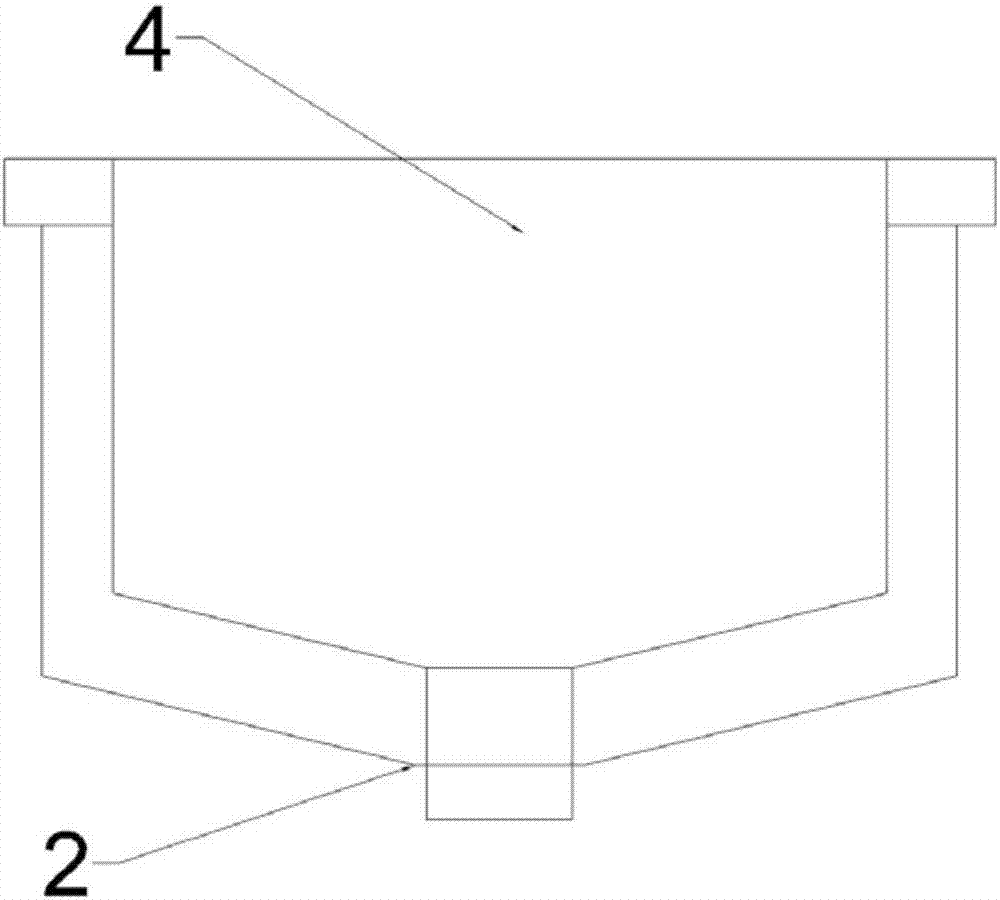

[0012] A kind of easy-to-clean sedimentation tank of this embodiment, such as figure 1 , 2 As shown, both sides of the bottom of the sedimentation tank 4 sink toward the middle, and the bottom of the sedimentation tank 4 is inclined toward one side as a whole; the sedimentation tank 4 is made of concrete, and ceramics are attached to its inner surface; there is a wave-proof grid in the middle of the sedimentation tank 4 3; One side of the sedimentation tank 4 has a water inlet 1, and the other side has a water outlet; the bottom of the sedimentation tank 4 is made into a mud discharge channel 2; the bottom of the sedimentation tank 4 is formed with a branch channel, and the branch channel is along the 4. The bottom is set and is perpendicular to the mud discharge channel 2, and the inner surface of the mud discharge channel is covered with a ceramic layer.

[0013] The anti-wave grid 3 of this embodiment is composed of three layers of grid cloth arranged at intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com