Internal grading ball mill

A technology of ball mill and internal classification, which is applied in the direction of solid separation, separation of solids from solids by air flow, and grain treatment, etc. It can solve the problems of affecting coarse material crushing, large floor space, and large equipment investment, and achieves the reduction of equipment. The effect of energy consumption, small occupied area and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

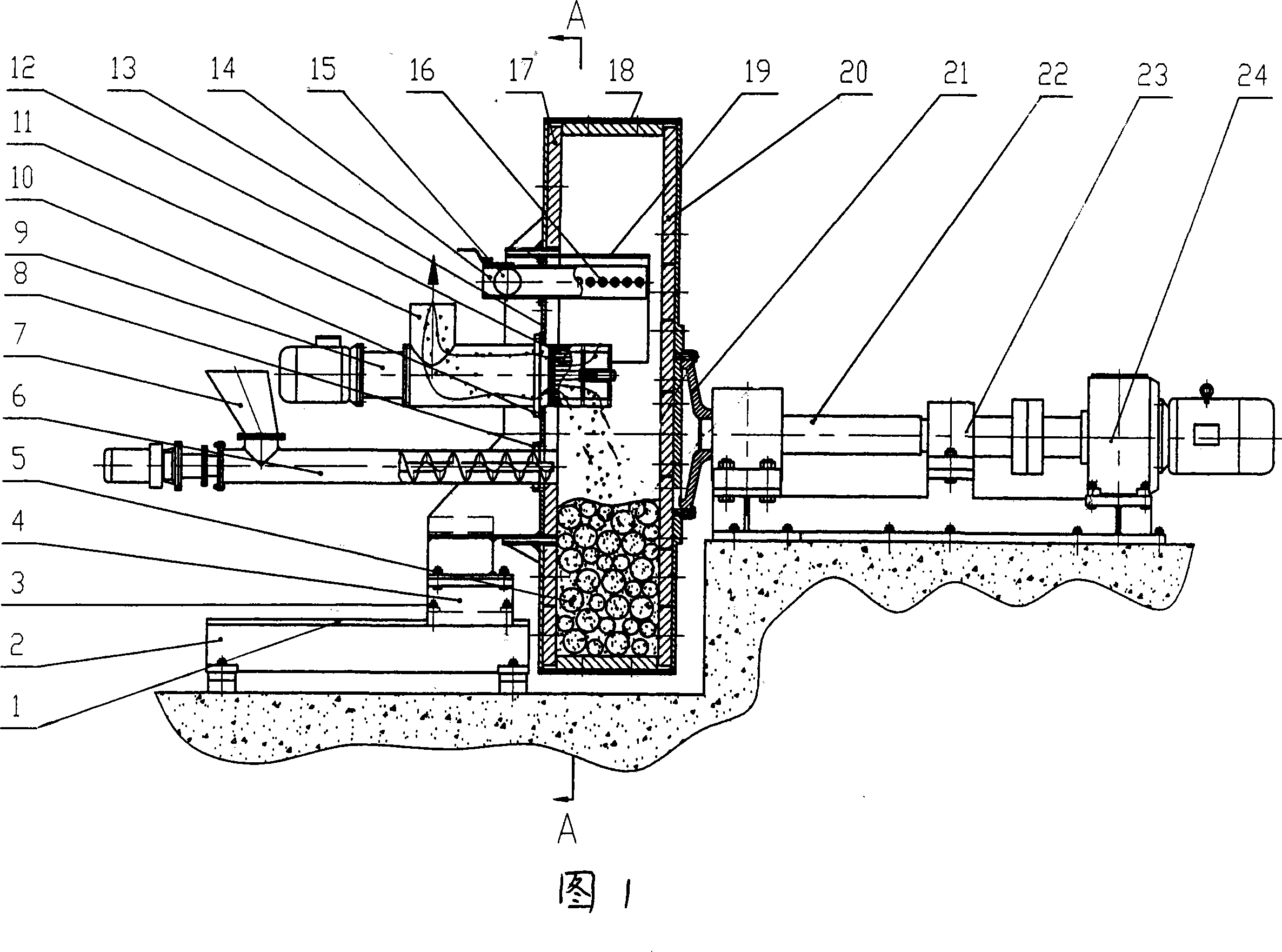

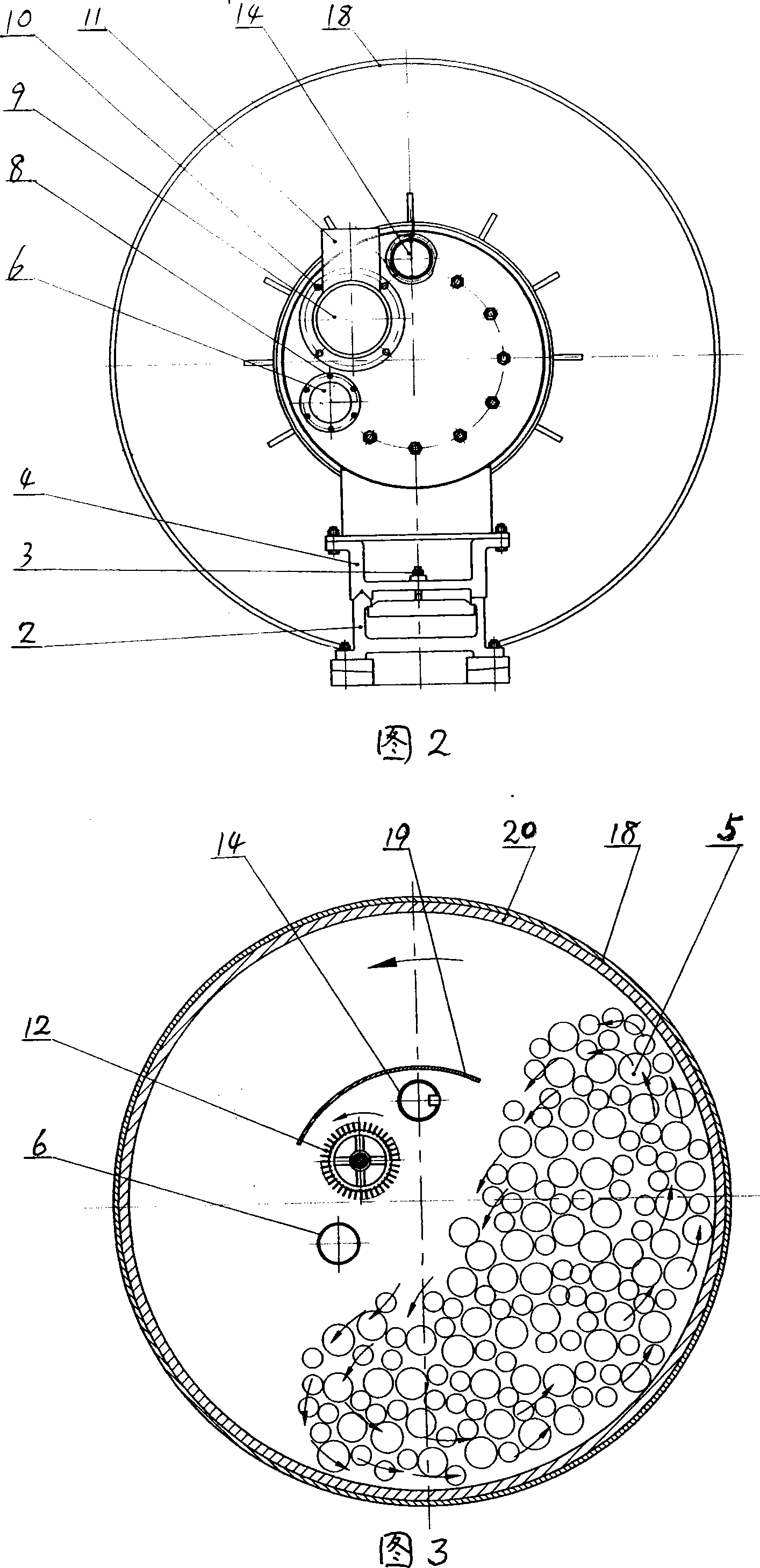

[0012] In the embodiment shown in the accompanying drawings, the present invention has a ball mill cylinder 18 driven to rotate by a transmission device 23. Said transmission device 23 includes a transmission shaft 22 driven by a motor through a transmission 24 and a shaft end flange fixed on the transmission shaft 22 21. The entire transmission device 23 is fixed on the ground foundation by bolts, and the center of one side of the ball mill cylinder 18 is connected with the shaft end flange 21 as a whole by bolts. Said ball mill cylinder 18 is a short ball mill cylinder, and its cylinder body length is 500-1500mm. The other side of the ball mill cylinder 18 is open, and a fixed static disc 13 is arranged at the opening position. The static disc 13 and the ball mill cylinder 18 form a ball mill cavity, and the ball mill 5 is housed in the ball mill cavity. The inner walls of the disc 13 are respectively inlaid with wear-resistant linings 20, 17 made of wear-resistant materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com