Selective crusher for underground use

A crushing and selective technology, which is applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of single discharge device, many faults of solid machine parts, and large noise, so as to achieve uniform particle size of the finished product and rapid and sufficient screening , the effect of large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

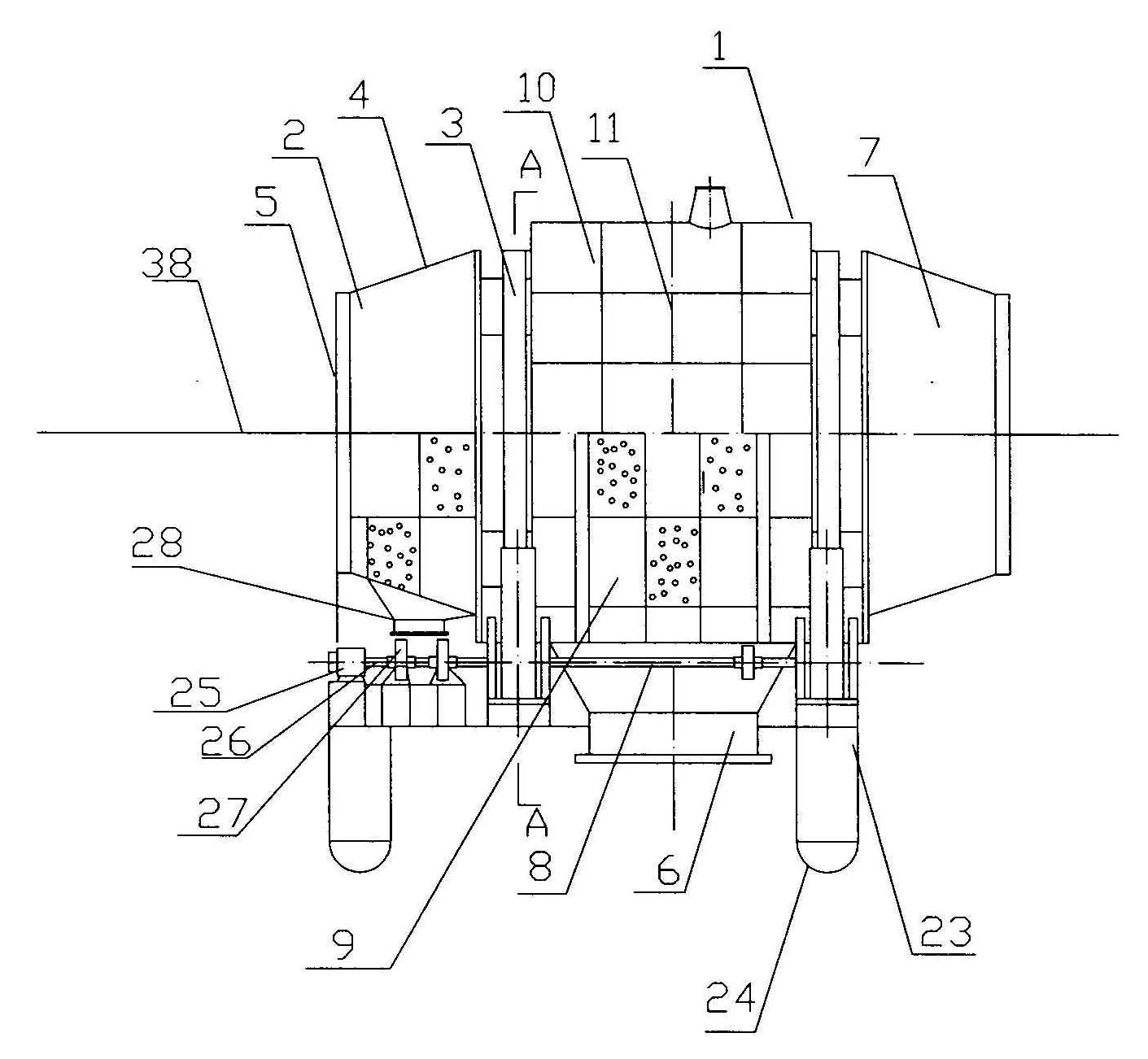

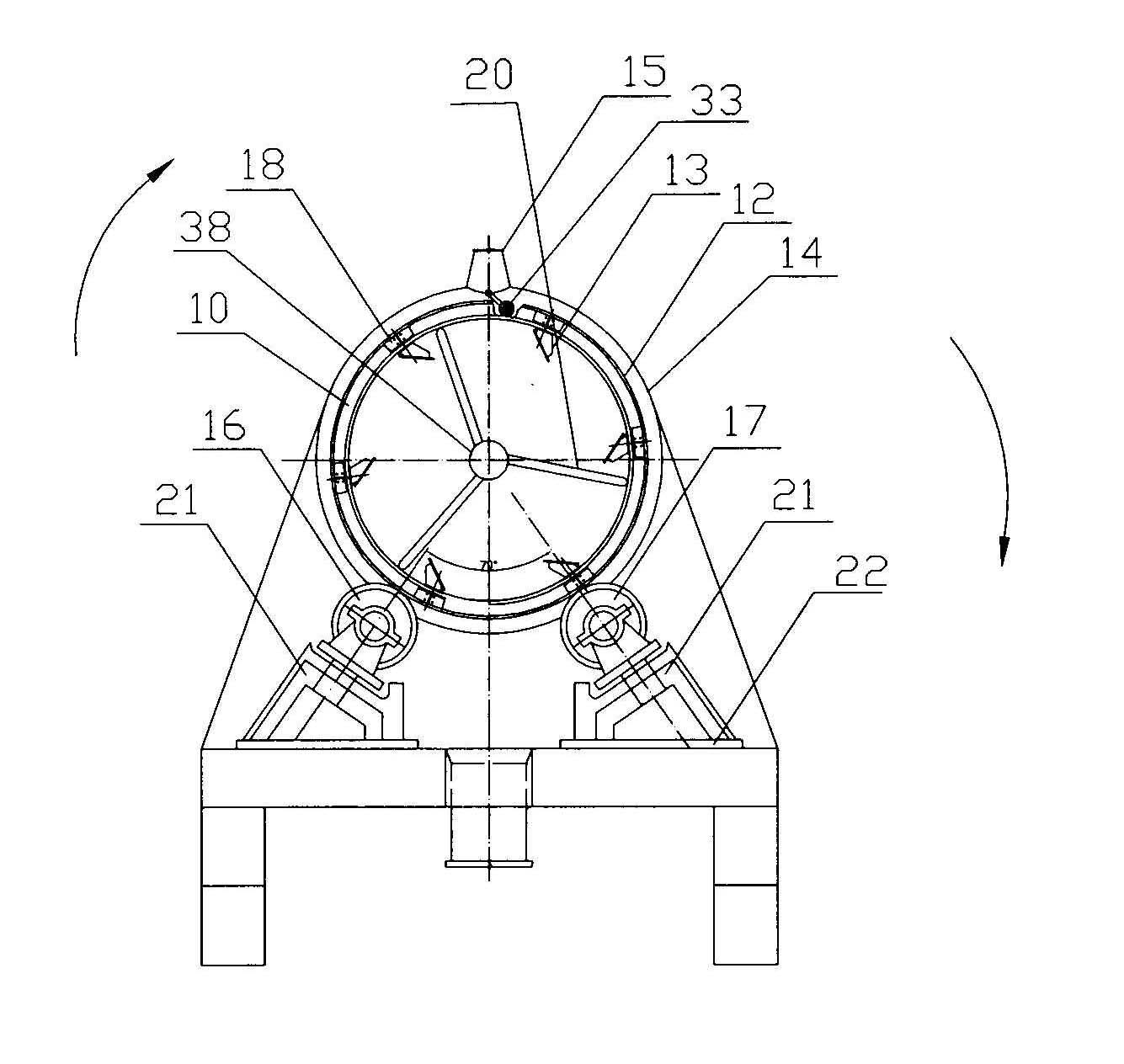

[0067] The lifting plate 13 involved in the present invention has a height of 300-500mm and is made of section steel. In order to make the material rotate forward along the drum, adjust the falling times and residence time of the material in the drum 10, while ensuring the falling times of the material , so that the material is discharged out of the cylinder as soon as possible.

[0068] The lifting plate 13 is installed in the following forms:

[0069] 1. The lifting plate 13 is axially parallel to the cylinder 10, and there is a certain angle (about 3°) between the axis of the cylinder and the horizontal plane.

[0070] 2. The lifting plate 13 has a certain included angle (about 3°) with the axis of the drum 10, and is arranged in a spiral shape, while the axis of the cylinder body can be parallel to the horizontal plane, and also has a certain included angle (about 3°-5°).

[0071] 3. The lifting plate 13 and the axis of the drum 10 are in the same plane. The drum screen i...

Embodiment 2

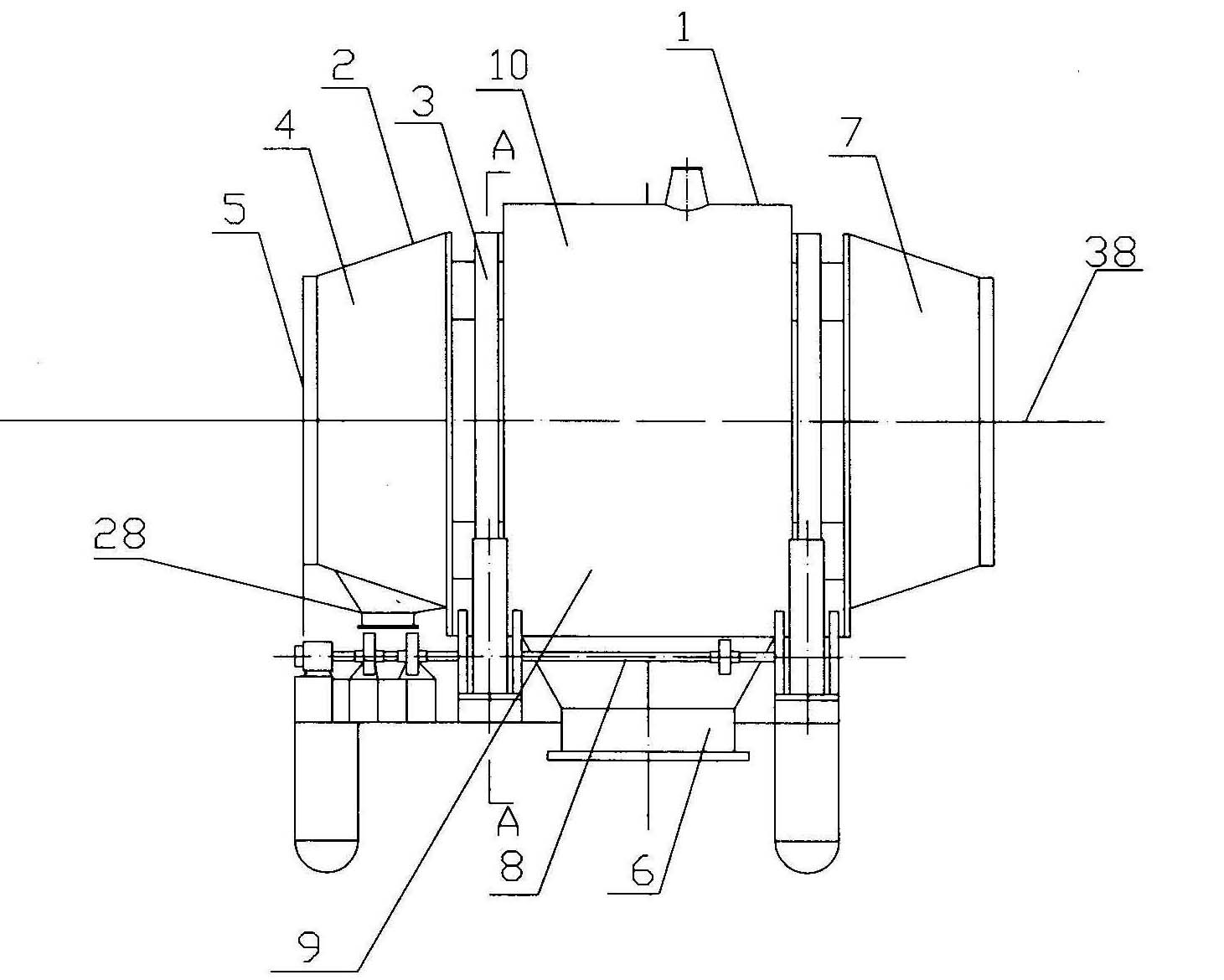

[0074] Drum 10 is composed of feed end 4, discharge end 7, beam 18 and plane drum sieve plate 31. The shape of the screen surface is a regular dodecagon, and the position corresponding to beam 18 on the inner wall of drum 10 is fixed by fastening bolts. 32 fixes the lifting plate 13 with a radial inclination.

Embodiment 3

[0076] The structure of the present invention can have the following different forms, which are different according to the properties and requirements of different materials.

[0077] 1. For the crushing of soft materials, each group of striking plates 35 can be increased to 6-8 pieces, which are evenly distributed, and the speed of the central shaft can be reduced at the same time.

[0078] 2. According to the generation law of mineral cracks, large materials will produce cracks under small impact force, while small and medium-sized materials will produce cracks and breakage under relatively large impact force, so the radius of rotation of the striking plate 35 on the central axis can be along the axial direction The feed end 4 to the discharge end 7 gradually increases to meet the requirements of the crushing law. Such as Figure 4 shown.

[0079] 3. Depending on the crushability of the material, the striking plate 35 on the central shaft can be tilted longitudinally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com