Novel bauxite comminuting process adopting vertical mill

A bauxite and vertical mill technology, applied in grain processing and other directions, can solve the problems of long grinding process, low solid content of qualified slurry, increased equipment investment and land occupation, etc., to simplify the grinding process, The feeding particle size is large, and the effect of improving the solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

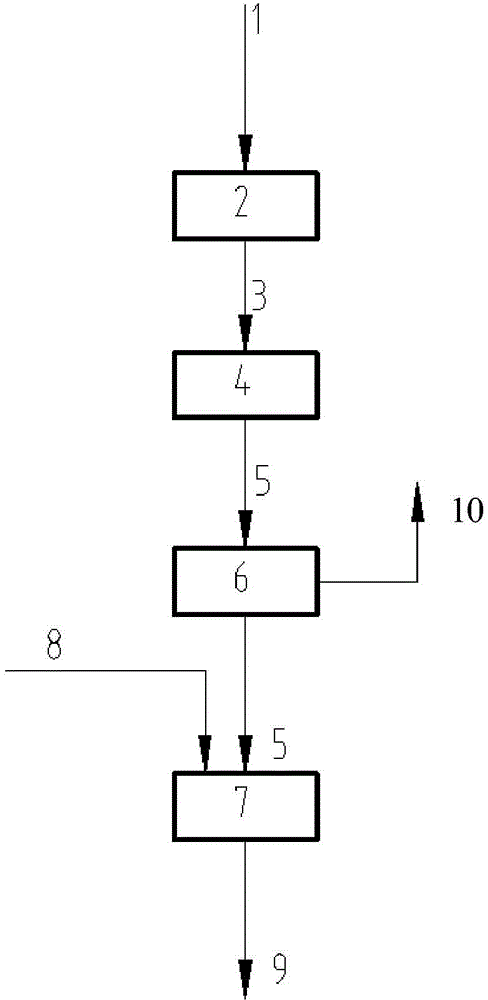

[0023] Such as figure 1 As shown, a large piece of bauxite 1 passes through the secondary crusher 2 to crush the ore to a qualified particle size of 40-100 mm, and the bauxite 3 with a qualified particle size after secondary crushing is fed into the vertical mill 4 . The bauxite entering the vertical mill 4 is ground under the action of the huge grinding pressure between the grinding disc and the grinding roller, and the bauxite 3 is crushed after intermediate crushing. Then, under the action of high-speed hot air from the bottom of the nozzle ring pipe at the bottom of the vertical mill 4 (hot air speed 10-50Nm) 3 / s, hot air temperature 100-300°C), the fine particles of bauxite are blown up and passed through the classifier for classification. After being classified by the classifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com