A limestone powder admixture processing system and processing method thereof

A processing system and limestone powder technology, applied in chemical instruments and methods, clay preparation equipment, mixing operation control, etc., can solve problems affecting project progress and increasing project cost, and achieve simplified operation, reduced operating energy consumption, and simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

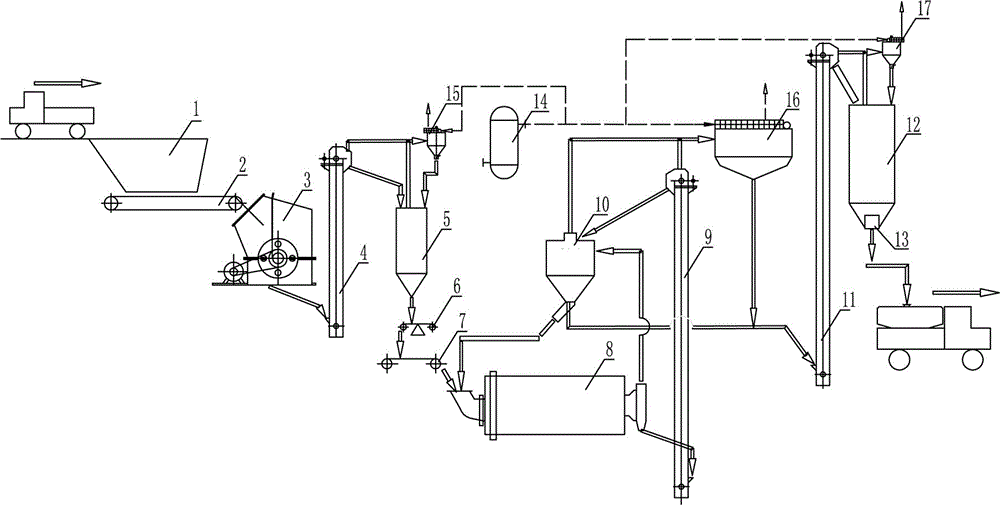

[0027] see figure 1 , a limestone powder admixture processing system, which includes a material receiving bin 1, an apron feeder 2 is arranged under the material receiving bin, and the discharge port of the apron feeder is connected with the feed port of the impact crusher 3, The discharge port of the counterattack fine crusher is connected with the feed port of the first hoist 4, the discharge port of the first lift is connected with the feed port of the regulating material tank 5, and an electronic device is arranged under the discharge port of the regulating material tank. The belt scale 6 is connected with a tape machine 7 under the electronic belt scale, the discharge port of the tape machine is connected with the feed port of the ball mill 8, the discharge port of the ball mill is connected with the feed port of the second elevator 9, and the second lift The discharge port of the machine is connected with the feed port of the powder separator 10, and the discharge port o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com