Patents

Literature

67results about How to "Improve Cloth Effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

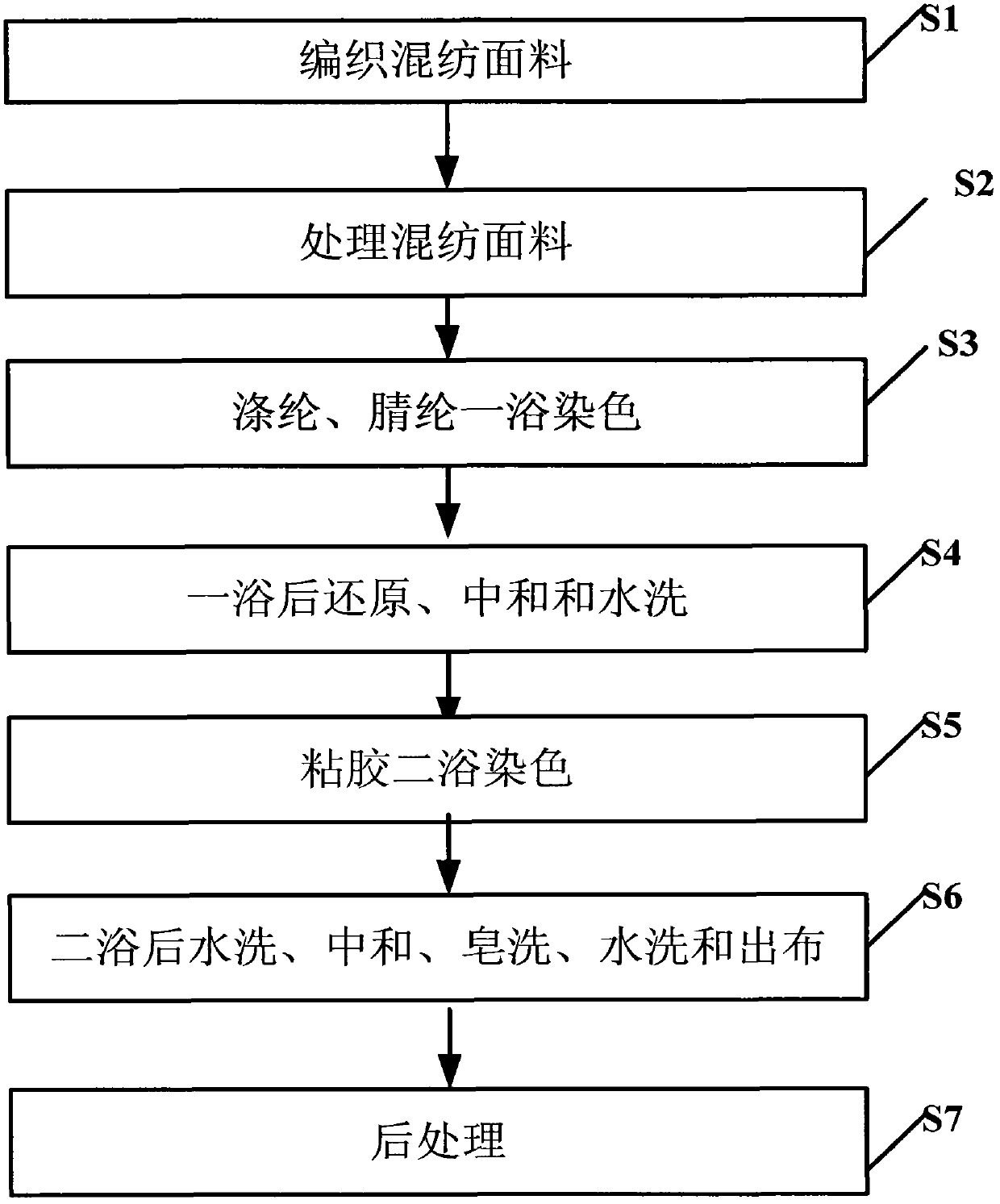

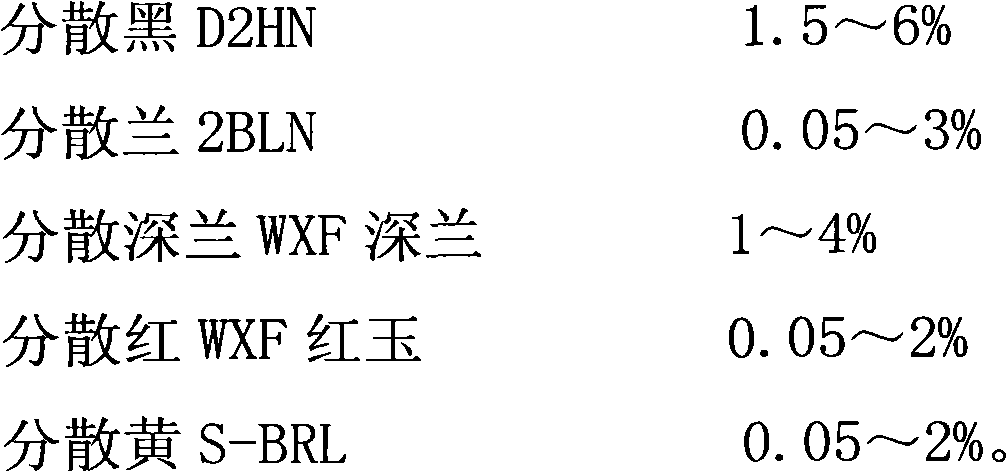

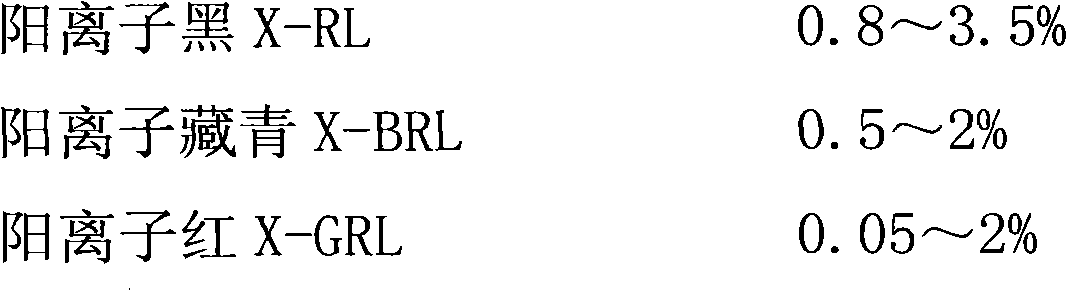

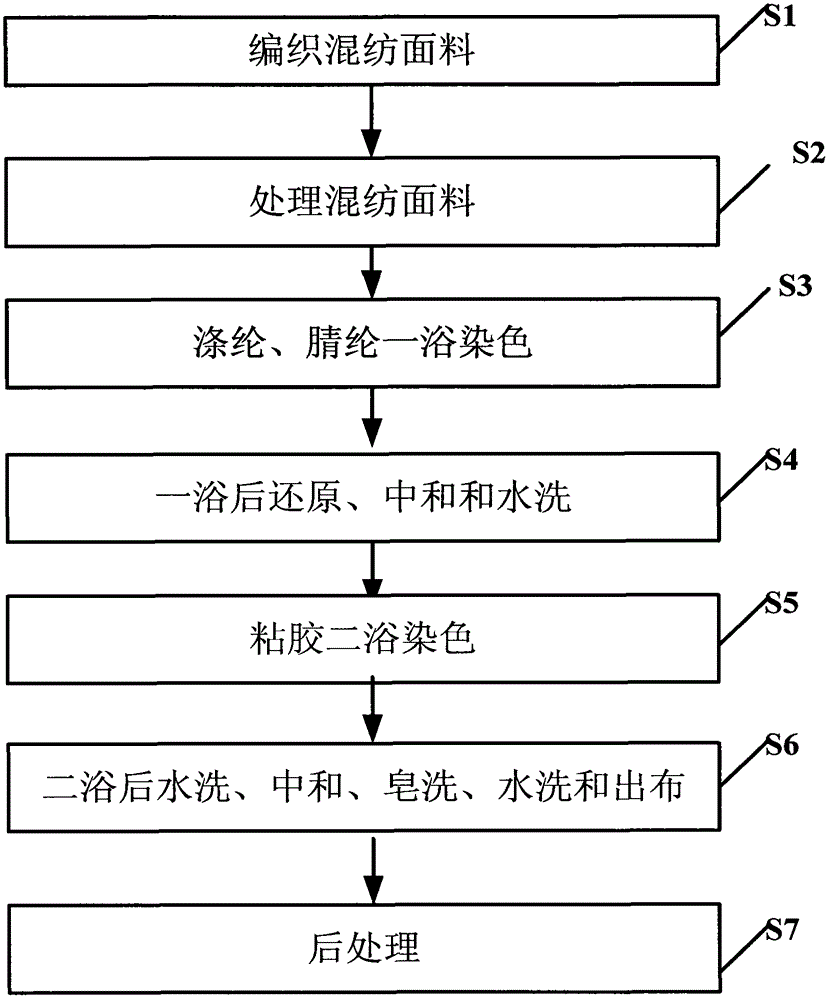

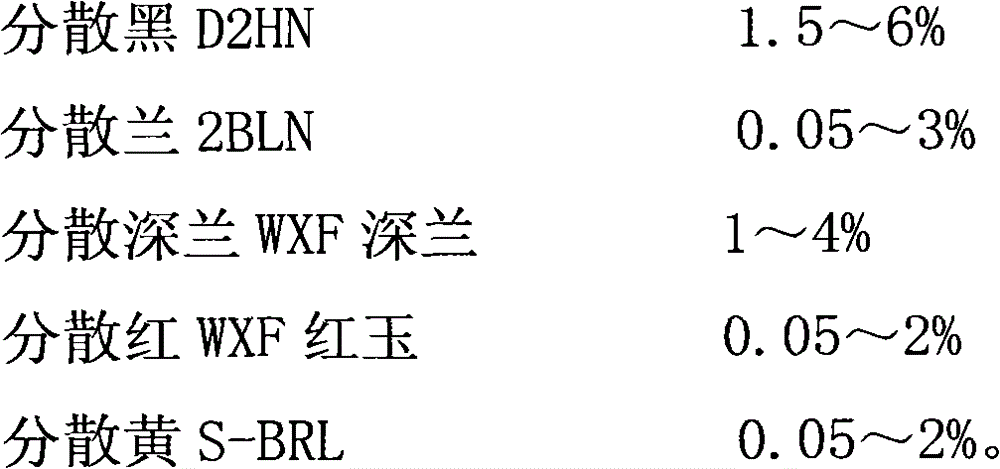

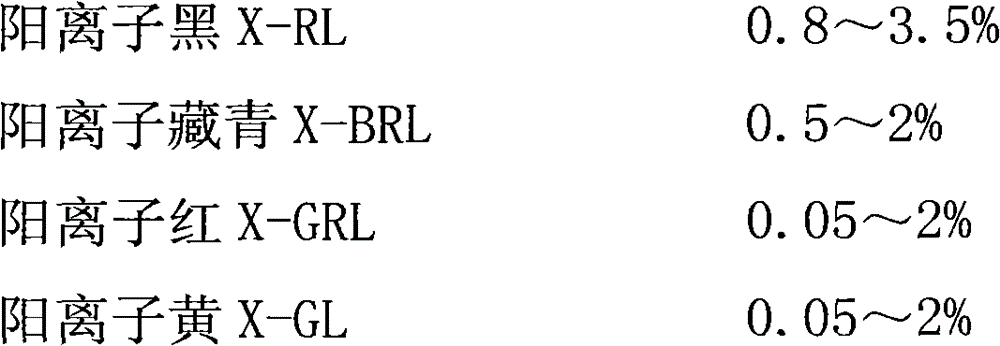

Dyeing method of terylene, acrylic fiber, viscose glue and spandex blended fabric

The invention discloses a dyeing method of a terylene, acrylic fiber, viscose glue and spandex blended fabric. The method comprises the following steps: 1, blended fabric weaving: weaving a blended fabric containing terylene, acrylic fiber, viscose glue and spandex; 2, blended fabric treatment: carrying out scotching presetting on a gray cloth, and linking; 3, carrying out one-bath dyeing on terylene and acrylic fibers; 4, reducing, neutralizing, and washing with water; 5, carrying out two-bath dyeing on the viscose glue; 6, washing with water, neutralizing soaping, washing with water, and discharging the obtained cloth; and 7, post-treatment: dehydrating the blended fabric obtained in step 6, drying, and carrying out scotching setting to obtain a finished product. The method has the advantages of simple process, fastness, efficiency, energy saving, convenient operation, stability, and dyeing of high-quality and stable-product-quality terylene, acrylic fiber, viscose glue and spandex blended fabrics.

Owner:GAOMI FUYUAN PRINTING & DYEING

Surfactant for woven fabric dye-bath retreat process and preparation method thereof

ActiveCN101709554AImprove Cloth EffectsHigh coloring rateDry-cleaning apparatus for textilesDyeing processChemistryWoven fabric

The invention discloses a surfactant for a woven fabric dye-bath retreat process and a preparation method thereof, wherein the surfactant comprises the following components in percentage by weight: 10-20 percent of sodium stearate, 20-30 percent of sodium dodecyl benzene sulfonate, 3-8 percent of polyoxyethylene nonyl phenyl ether, 30-40 percent of dispersing agent MF and the balance of water. The preparation method comprises the following steps of: adding water into the sodium stearate for dilution so as to prepare a solution with the concentration of 5-8 percent; then, adding the solution into a reaction kettle, and heating to the temperature of 70+ / -5 DEG C; sequentially adding the sodium dodecyl benzene sulfonate and the polyoxyethylene nonyl phenyl ether, fully stirring and mixing; and finally, cooling to the temperature of 35+ / -5 DEG C, adding the dispersing agent MF after foams naturally disappear, fully stirring and mixing to prepare the surfactant. The product can prevent the reattachment of slurry and impurities, and improve the dyeing quality.

Owner:石狮市万峰盛漂染织造有限公司

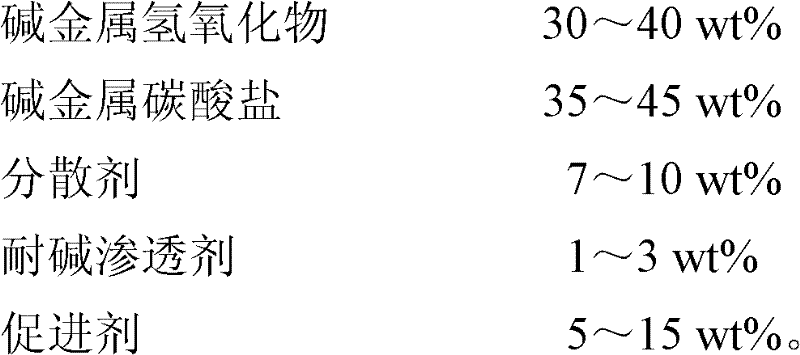

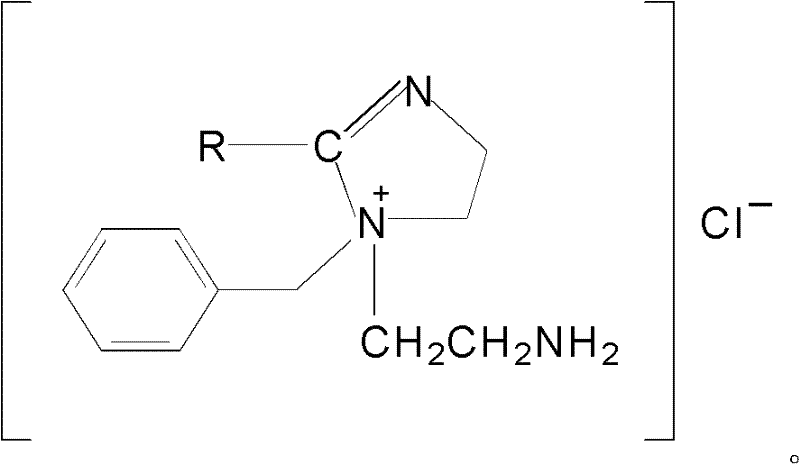

Color fixing substitution alkali for low-salt dyeing by using reactive dye pad steaming process

The invention relates to color fixing substitution alkali for low-salt dyeing by using a reactive dye pad steaming process, and the color fixing substitution alkali can be applied to low-salt color-fixing treatment on a cotton fabric dyed with a reactive dye. The color fixing substitution alkali is an organic / inorganic composite buffer system consisting of alkali metal hydroxide, alkali carbonate, a dispersing agent, an alkali-resistant penetrating agent and an accelerating agent. The traditional color-fixing alkali agent for the reactive dye is replaced and low-salt dyeing is realized under the condition of not changing the traditional technological equipment and flow. The color-fixing substitution alkali agent has the characteristics of low consumption, favorable stability, convenience for operation, and the like, meanwhile, is beneficial to reduction of production cost and environment pollution, has little influence on the equipment and meets the requirements on energy saving, emission reduction and efficiency increase.

Owner:FUJIAN QINGYUAN TECH

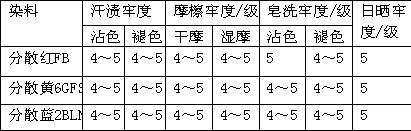

Polyester/sorona mixed fabric disperse dye one-bath process dyeing method

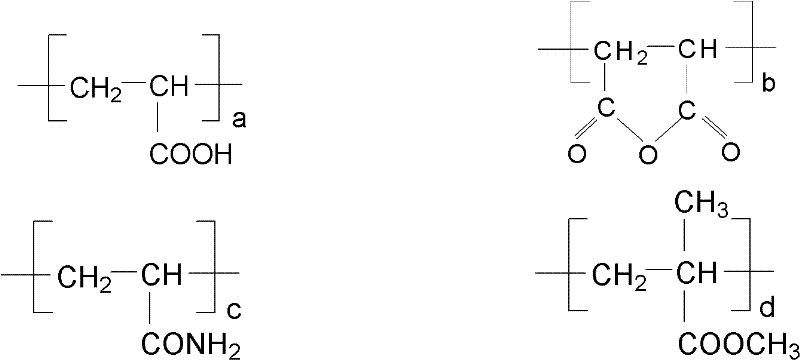

InactiveCN103215831AImprove qualityShade stabilityDry-cleaning apparatus for textilesDyeing processDisperse dyeColour fastness

The invention relates to a polyester / sorona mixed fabric disperse dye one-bath process dyeing method. According to the determined optimal dyeing process of polyester / sorona mixed fabric, the dye dosage is greater than or equal to 2% (owf), the pH value is 5.5, the dyeing time is 50 minutes, the dyeing temperature is 110 DEG C, and the carrier dosage is 1.5g / L. The result indicates that the dyeing method can obtain a product with stable color light, good homochromatism and high color fastness; and the process is simple, the time is short, and the production cost is low.

Owner:JIANGYIN POLYTECHNIC COLLEGE

Method for processing no-iron 100% bombast

ActiveCN1932137AGood flexibilityDimensionally stableBiochemical fibre treatmentVegetal fibresYarnAfter treatment

The present invention discloses a processing method of all-flax flexible self-smoothing face fabric. It is characterized by adding the processes of tensionless desizing and enzyme treatment in the face fabric finishing stage, and its whole processing method includes the following several steps: loosening yarn, pretreatment, dyeing, after-treatment, coning, weaving, gray inspection, singeing, tensionless desizing, enzyme treatment, liquid ammonia finishing, finalizing design and re-shrinking.

Owner:盛泰智造集团股份有限公司

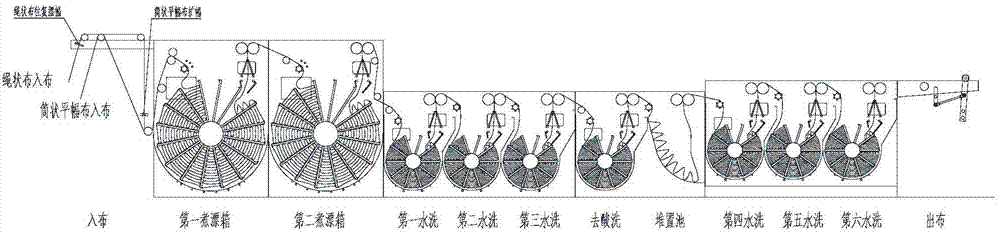

Heat preservation technology for continuous dip bleaching stage of one bath one step method for cotton fabric and cotton blended fabric

ActiveCN104846576AVersatilitySuitable for flexible productionTextile treatment containersSucessive textile treatmentsElectricityFiber

The invention discloses a heat preservation technology for a continuous dip bleaching stage of a one bath one step method for cotton fabric and cotton blended fabric. According to the heat preservation technology, based on the prior art, a structure comprising a boiling box and a washing machine is improved to a sealed drum structure with an impeller so that the fabric can be fully spread and will not cluster or gather or form a pile in the processing process, and the boiling off effect and the blenching effect are good; the fabric is boiled and blenched at a low temperature firstly and then boiled and blenched at a high temperature, so that the decomposition rate and the decomposition products of hydrogen peroxide are effectively controlled, various kinds of processing liquid flow in the direction opposite to the movement direction of the fabric in a drum, and therefore the processing effect is further improved; through the continuous production mode, the good boiling-off effect and the good blenching effect are achieved, the degree of oxidative damage to fibers is reduced to the greatest extent, the production efficiency is high, the consumption of water, electricity and steam is low, technical control is simple, adjustment is convenient, and flexible production can be achieved.

Owner:QINGDAO UNIV

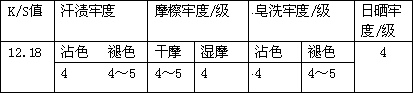

Technology using vaccinium bracteatum plant dye for dyeing of black blue real silk

InactiveCN105369654AWidely distributedAchieve plantingNatural dyesDyeing processVaccinium bracteatumWater baths

The present invention relates to a technology using a vaccinium bracteatum plant dye for dyeing of real silk, the technology includes 60 DEG C water bath extraction of the vaccinium bracteatum plant dye and low temperature environmental-friendly dyeing, the dyeing is as follows: wetting real silk, squeezing to dry, putting the real silk into the plant dye with the bath ratio of 1:20 to 1: 30, adding a mordant or not, heating the water bath to 50-75 DEG C at a heating rate of 1.5 DEG C / min for thermal insulation dyeing for 1-2h; taking a dyeing cup out, standing at room temperature for 7-8h; after the dyeing, steaming the real silk at the temperature of 100-103 DEG C for 10-15min, after washing with water, boiling with soap at 90-100 DEG C for 5-10min, and finally drying at 50-60 DEG C. The obtained real silk has a rare black blue color and special natural flower and plant fresh scent.

Owner:JIANGYIN POLYTECHNIC COLLEGE

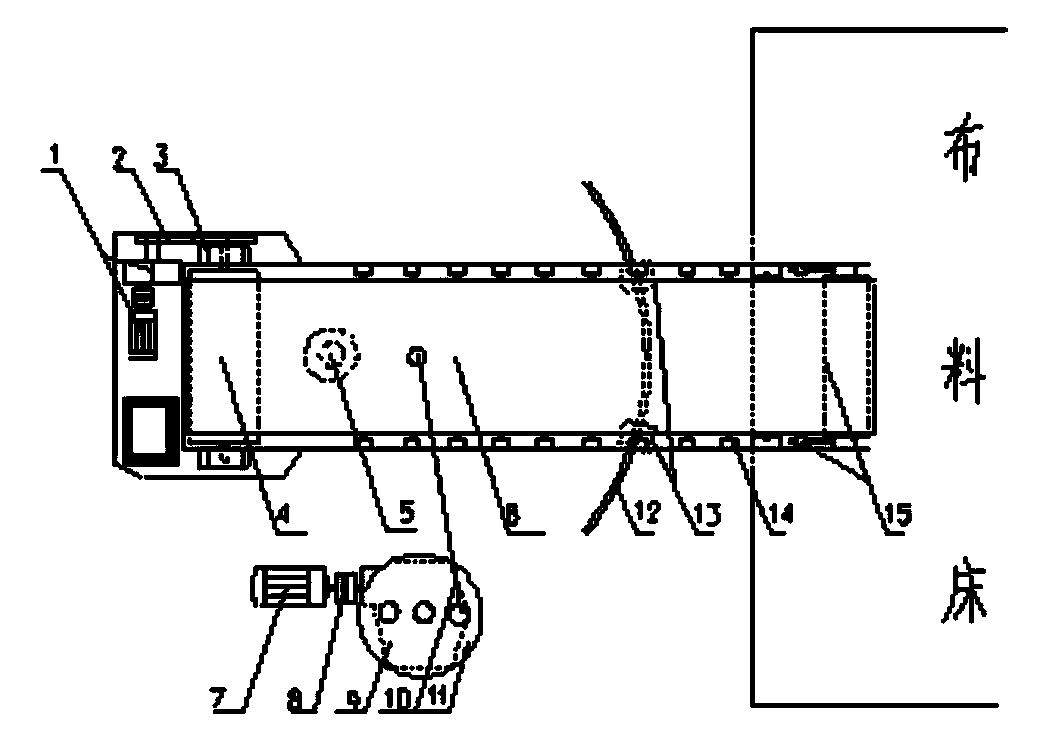

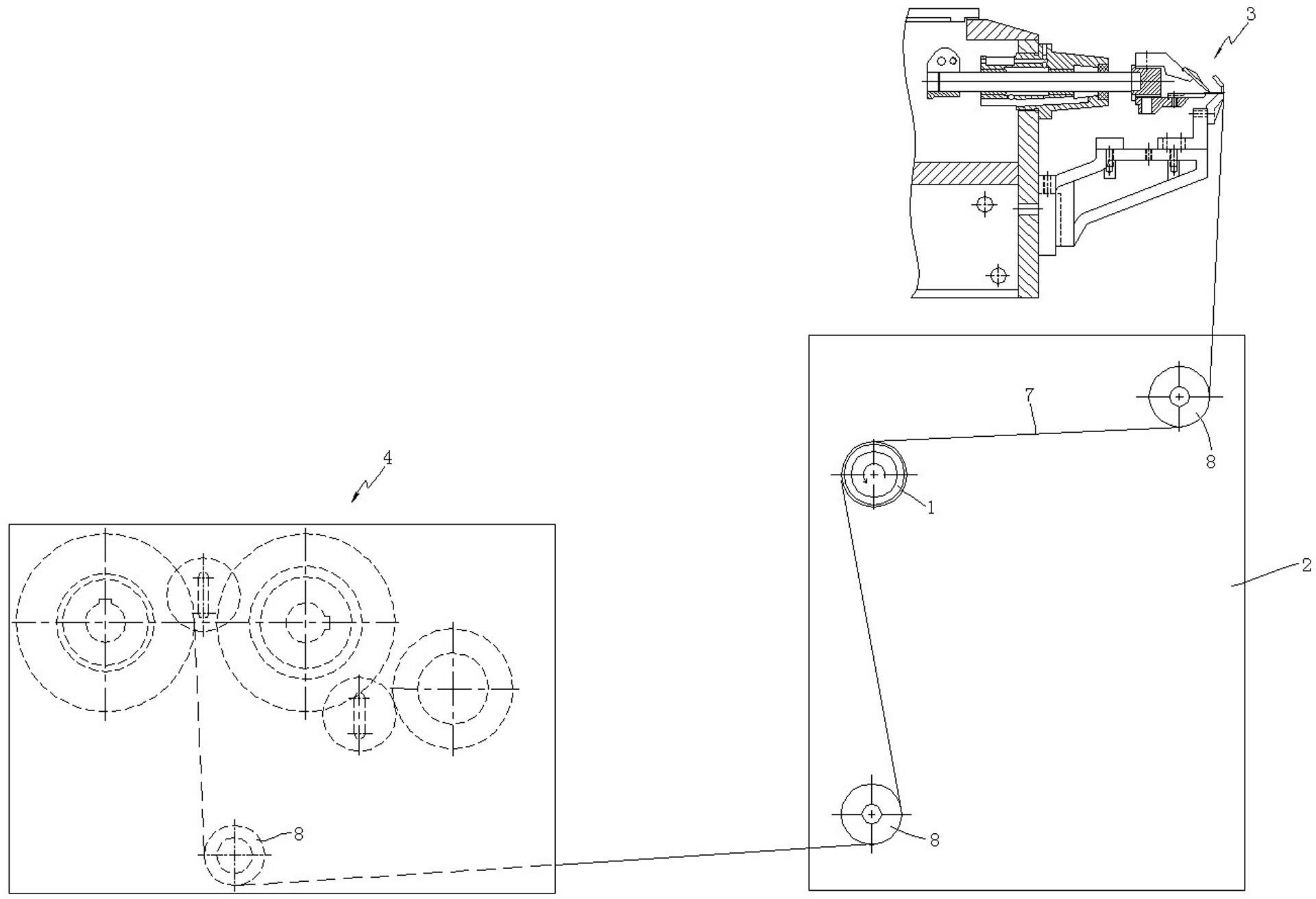

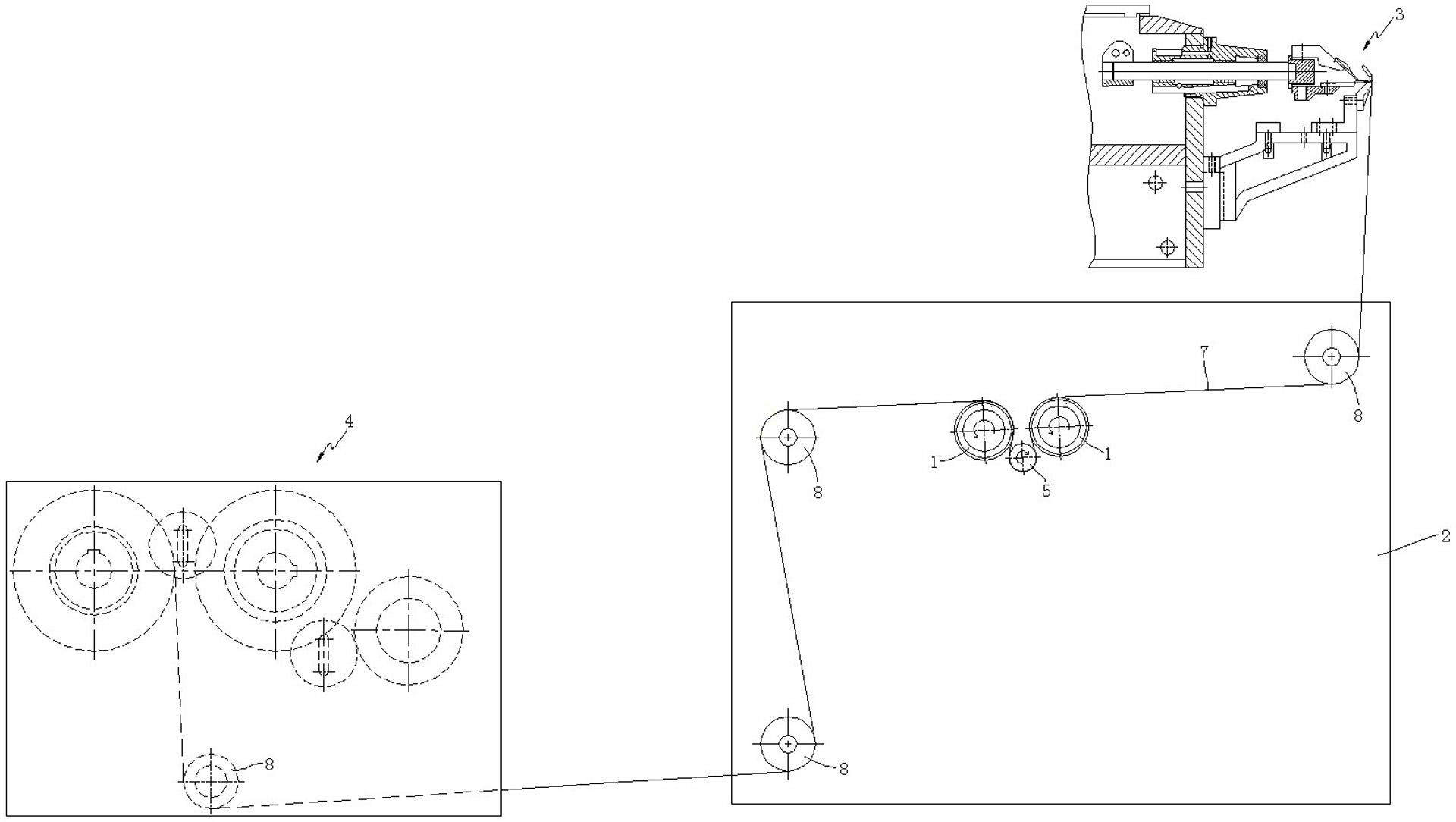

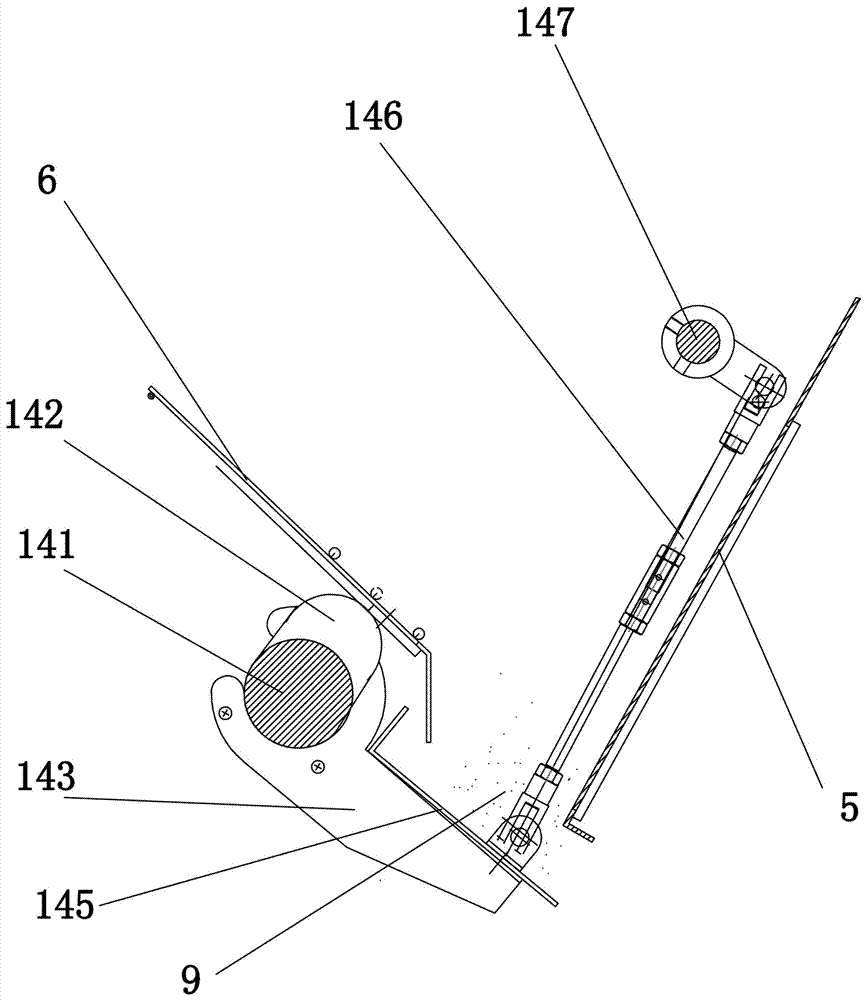

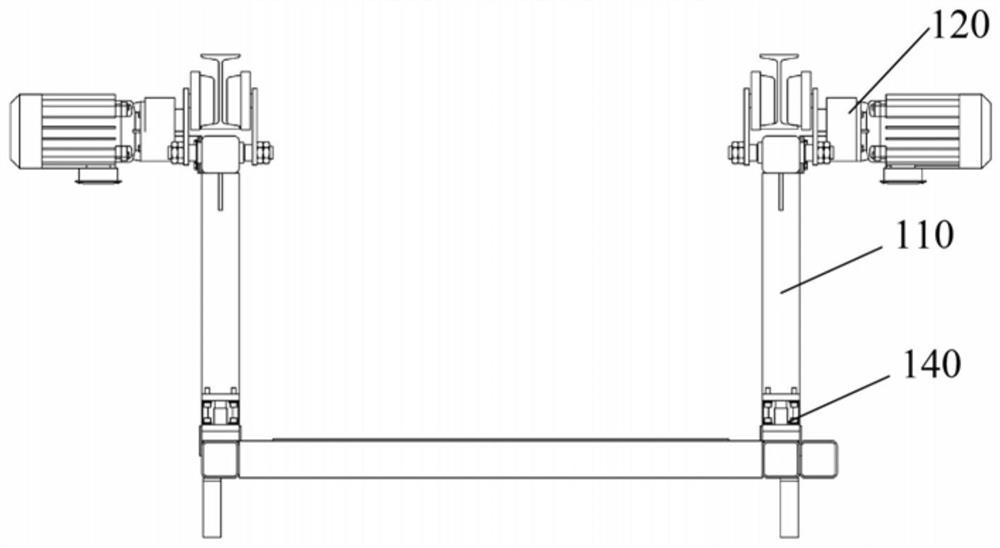

Swing-type belt distributing device and method for determining sizes of gears of elliptical gear case of swing-type belt distributing device

The invention relates to a swing-type belt distributing device and a method for determining the sizes of gears of an elliptical gear case of the swing-type belt distributing device. In order to solve the problem that an existing distributing device is uneven in distributing, the swing-type belt distributing device comprises a transmission motor reduction box, a chain wheel chain, a bearing pedestal, a main wheel, a main shaft, an adhesive tape, a swing motor, a connecting handle, a swing reduction box, a connecting rod, a crank, an arc-shaped track, a walking wheel, a carrier roller, a bend wheel and an adjusting device. The swing-type belt distributing device further comprises the elliptical gear case between the crank and the swing reduction box, the elliptical gear case internally comprises the two gears which are the same in size and shape, an output shaft of the driven elliptical gear is connected with the crank, and an output shaft of the driving elliptical gear is connected with an output shaft of the swing reduction box. By means of the swing-type belt distributing device and the method, the linear speeds at the two ends and the linear speed in the middle of the swing-type belt distributing device are effectively improved, the linear speeds can be basically kept coincident, the effect of even distributing on a transverse bed of the swing-type belt distributing device in a relatively equal-thickness mode is achieved, and the swing-type belt distributing device is simple in structure and low in cost.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

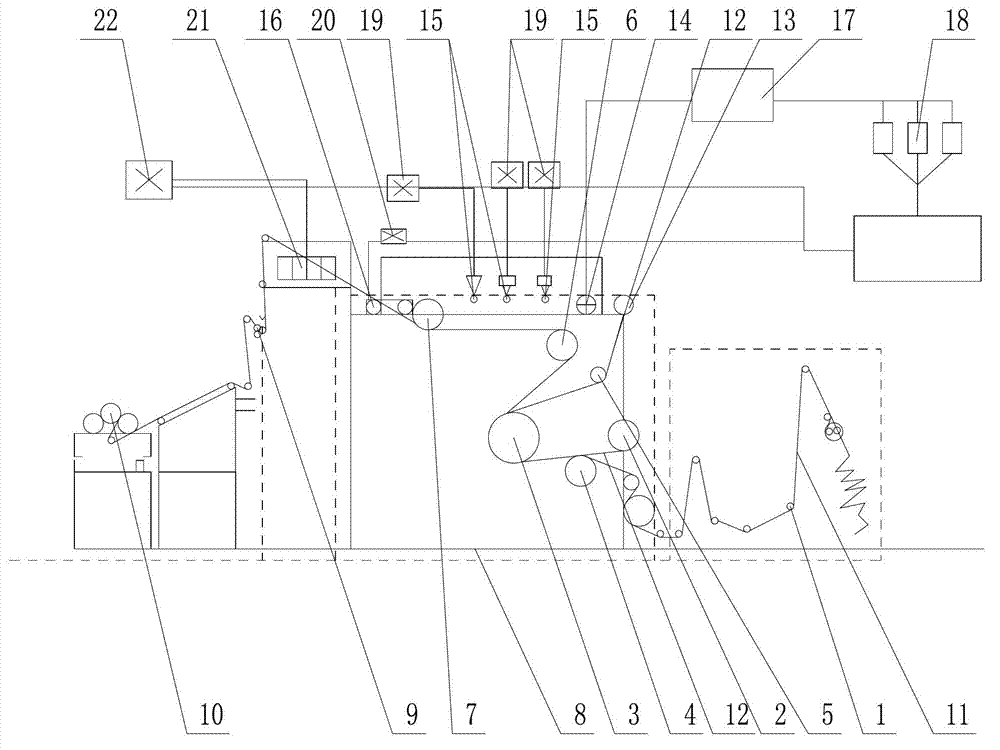

Textile cloth spray-drying system

InactiveCN106995992AGood effectUniform spray holeSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersEngineeringUtilization rate

The invention discloses a textile cloth spray-drying system, comprising a dye box (1); a plurality of dye nozzles (2) are arranged in the dye box (1); one end of the dye box (1) is provided with a heating box (3); the other end of the heating box (1) correspond to the dye box (1) is provided with a rinsing box (5); a dye filter (9) is connected below the bottom of the dye box (1); the other end of the rinsing box (5) corresponding to the heating box (3) is provided with a dewatering box (7); the other end of the dewatering box (7) corresponding to the rinsing box (5) is provided with a drying box (19); two cloth feeding rollers (20) and two cloth drawing rollers (21) are connected to two ends of the drying box (19) respectively; an electric heating plate (22) is arranged in the drying box (19); a controller (23) is arranged at the top end of the drying box (19). The textile cloth spray-drying system is good in dyeing uniformity, lower in cost, higher in dye utilization rate, and good in environment-protecting and dyeing effect, and also has the advantages of good cloth-drying effect and zero cloth deformation.

Owner:湖州南浔凯普纺织有限公司

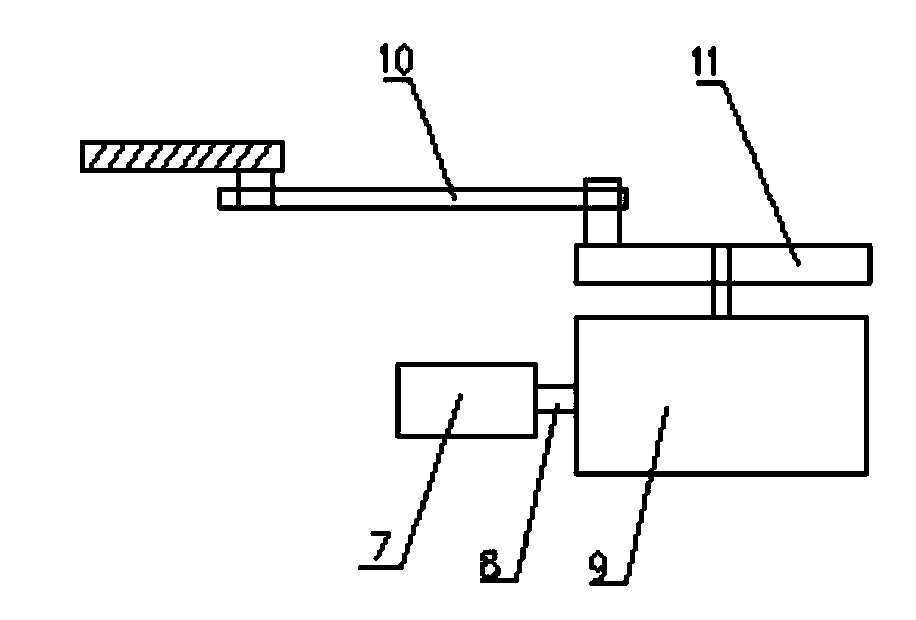

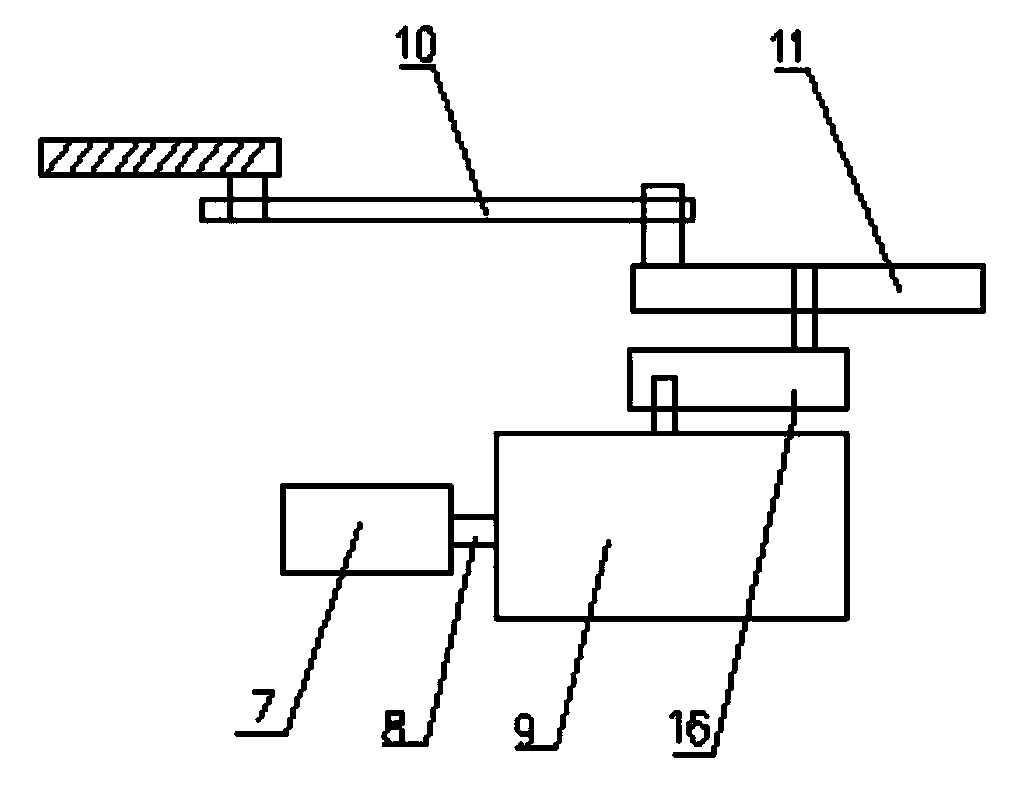

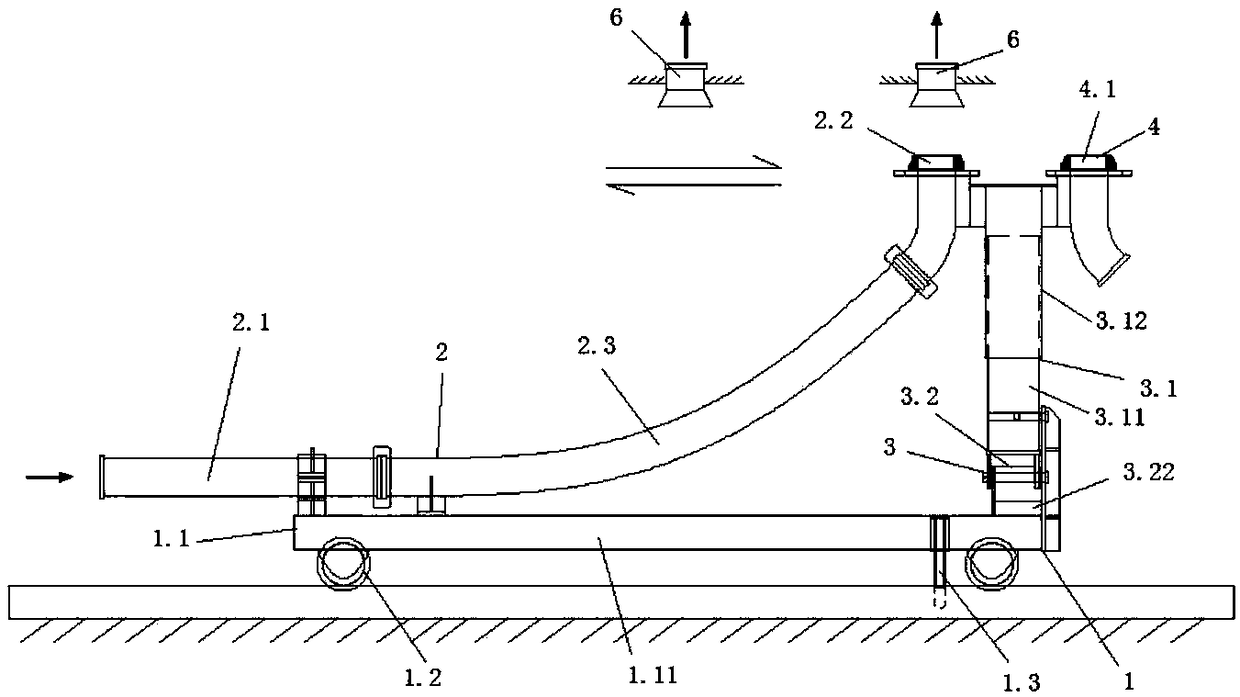

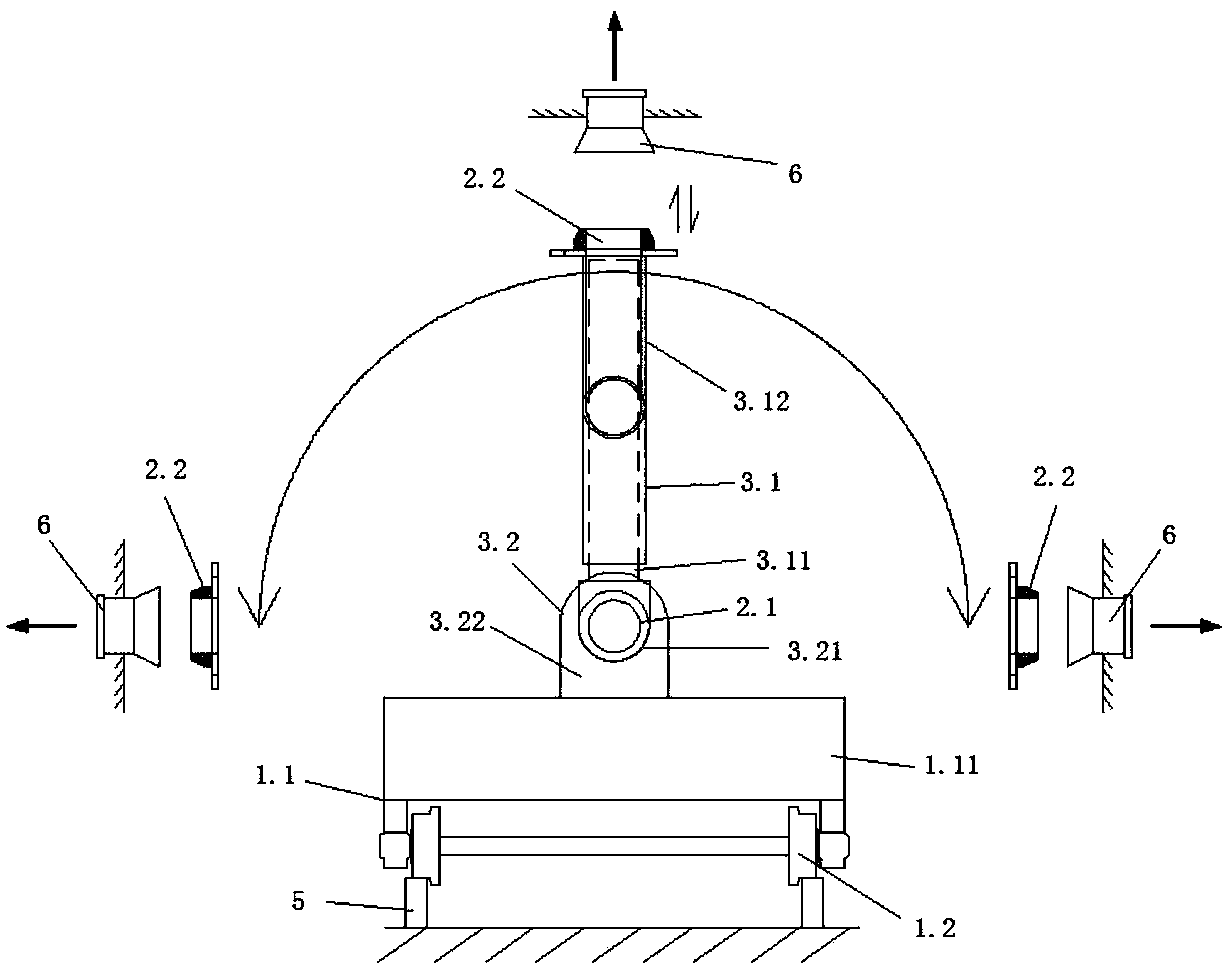

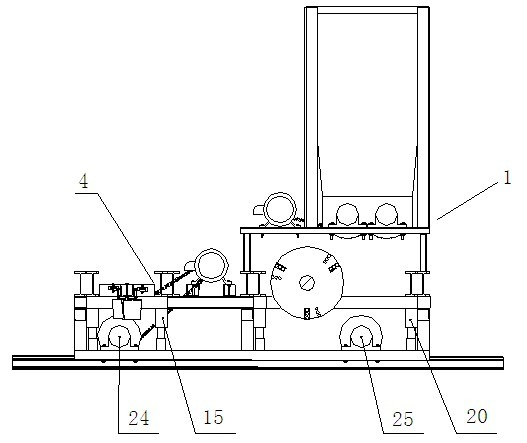

Concrete distributing machine

PendingCN108798706AEvenly distributedImprove Cloth EffectsUnderground chambersTunnel liningEngineeringOn demand

The invention provides a concrete distributing machine which comprises a trolley, a pipeline system and a telescopic rotating device. The trolley comprises a trolley body, a travelling part and a locking part, and the trolley body comprises a bottom plate. The pipeline system comprises a feeding pipe set, a discharging pipe set and a connecting pipe set, the feeding pipe set is connected with a concrete pumping mechanism, and the connecting pipe set is movably arranged on the trolley body through the telescopic rotating device. By applying the technical scheme of the concrete distributing machine, the effects are that the whole structure is simplified; through combination design of the trolley body and the travelling part, the trolley body advantageously travels by a certain distance on demand; through combination design of the trolley, the pipeline system and telescopic rotating device, the spatial relationship of all pipelines in the pipeline system is advantageously changed, the change of the distance and the position is achieved, then combined with connection of the concrete pumping mechanism, pressurized closed feeding is achieved, concrete distribution is uniform, and the grouting efficiency and the quality of grouted concrete products are greatly improved; and through design of the locking part, the position of the trolley body is advantageously fixed, and the distributing effect of the distributing machine is further optimized.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

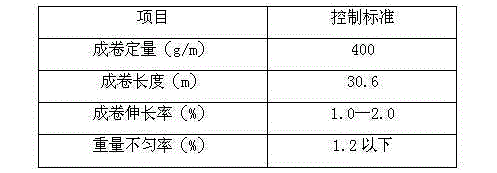

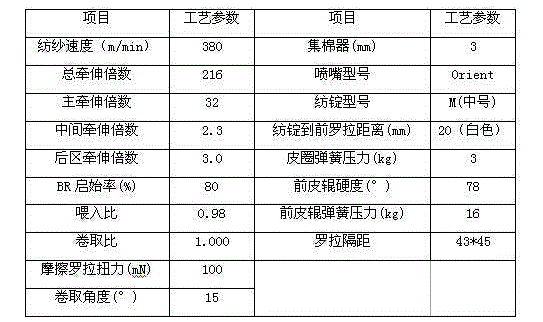

Wine red superfine denier yarn bamboo fiber and special-shaped colored polyester fiber blending product and spinning method thereof

The invention discloses a wine red superfine denier yarn bamboo fiber and special-shaped colored polyester fiber blending product and a spinning method thereof. The wine red superfine denier yarn bamboo fiber accounts for 92 percent of the weight, the special-shaped colored polyester fiber accounts for 8 percent of the weight, and the blending product is 14.8 tex. The invention further discloses the spinning method of the product. Various original characteristics of the bamboo fiber are retained, the pollution to the environment and the waste of water resources from a traditional processing technology are greatly reduced, and compared with a traditional technology that spinning and dyeing are carried out in sequence, the water is saved by about 50 percent, and the waste water is reduced by about 50% in a colored spun yarn production technology; obvious advantages exist in the aspects such as energy conservation, emission reduction and environmental friendliness. In the color aspect, the colored spun yarn product can display multiple colors on the same yarn, the colors are abundant, full and soft, and the fabric woven through the colored spun yarn product has the hazy three-dimensional effect. Meanwhile, the dyeing technology of the colored spun yarn product is unique, and high technical content is achieved in the aspects such as fiber dyeing, color matching and multi-fiber blending. The product greatly meets the requirements of people for fashion, bright colors, colorfulness and the like and has high market value.

Owner:SHANDONG YANGGU SHUNDA TEXTILE

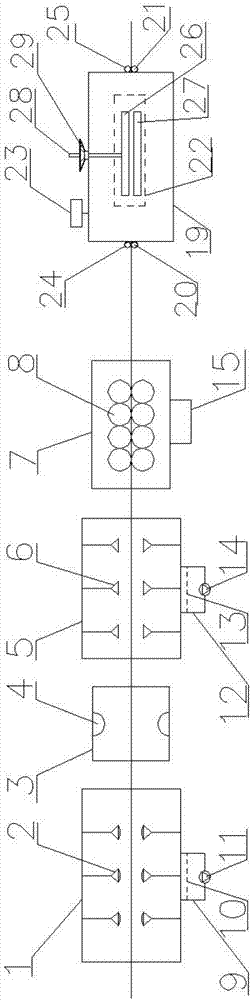

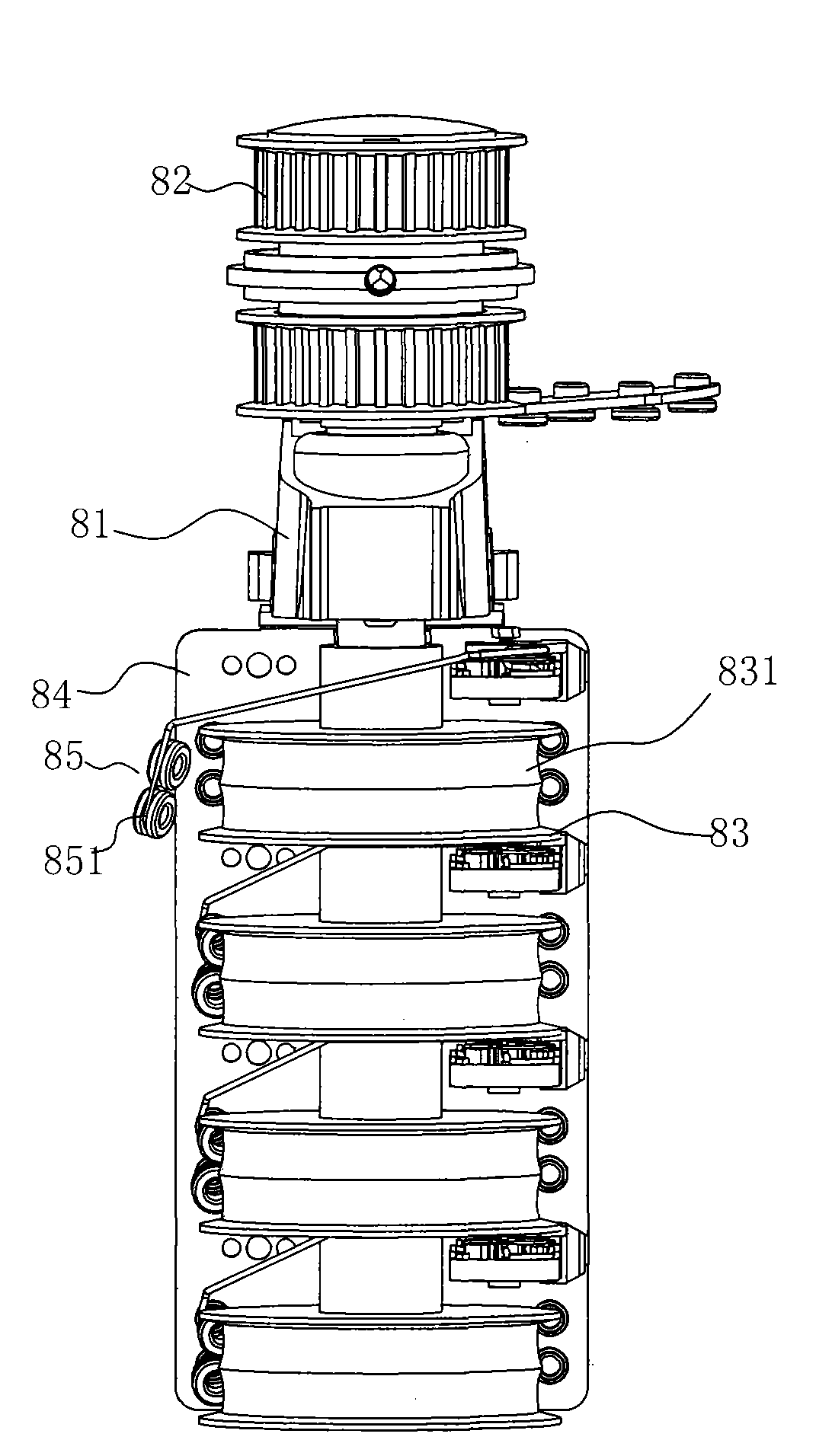

Sectional type all-in-one machine for distributing, breaking, cutting, turning, throwing and collecting sludge

InactiveCN102627385AWith sludge breaking functionWith up and down lift functionSludge treatment by de-watering/drying/thickeningSludgeEngineering

The invention discloses a sectional type all-in-one machine for distributing, breaking, cutting, turning, throwing and collecting sludge, which comprises a feeding device, a distributing, breaking, cutting and collecting device, a turning and throwing device, a walking mechanism and a hydraulic mechanism. The feeding device is connected with the distribution, breaking, cutting and collecting device through the walking mechanism, the turning and throwing device is connected with the feed device, and the hydraulic mechanism is connected with the distributing, breaking, cutting and collecting device and a turning and throwing device. The sectional type all-in-one machine has the functions of distributing, breaking, cutting, turning, throwing and collecting sludge. An angle of a scraper plate of a distributing mechanism can be adjusted in distributing and collecting operation, distributing effect is good, the distributing mechanism has the functions of breaking and cutting sludge, and drying efficiency rises. The distributing mechanism can go up and down and can effectively collaborate with a turning and throwing mechanism. The turning and throwing mechanism can go up and down, and the thickness of turning and throwing can be adjusted. By means of the turning and throwing mechanism of a toothed structure evenly distributed along the circumferential direction and staggered in the axial direction, 360-degree rotation can be achieved.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

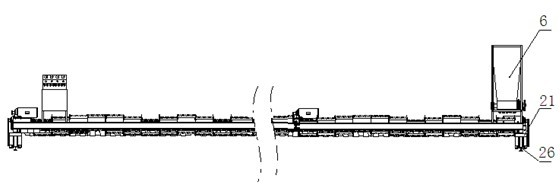

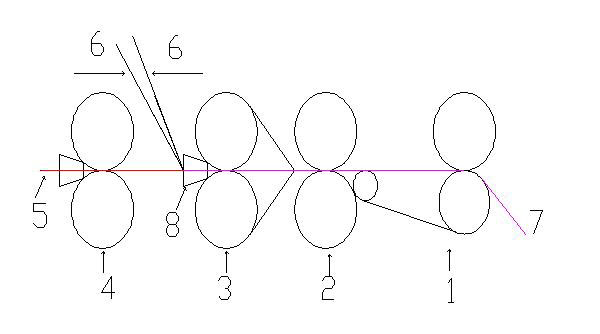

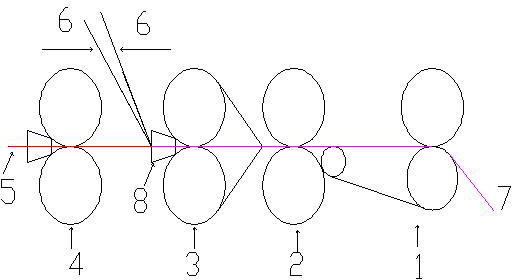

Improved ring spinning frame and spinning process thereof

InactiveCN102071500AClosely arrangedReduce widthDrafting machinesContinuous wound-up machinesYarnEngineering

The invention belongs to the field of spinning, specifically to an improved ring spinning frame and a spinning process thereof. The improved ring spinning frame comprises a back roller, a middle roller, a second roller and a front roller in turn. The improved ring spinning frame is characterized in that the back roller and the middle roller are provided with a feeder which consists of a suspended spindle and a flare opening; a servo motor for controlling the back roller is provided with a variable speed intelligent controller which is connected with an encoder arranged on the front roller; the output opening of the front roller is provided with a suction groove and a deformed pipe with negative pressure; a grid ring is sleeved on the deformed pipe, and is drawn through a leather roller. The invention is capable of shortening the process flow, increasing the production efficiency and lowering the production cost; and moreover, the spun yarn is excellent, little in hairiness, high in strength and variety in colors.

Owner:SHANDONG HUALE NEW MATERIAL TECH

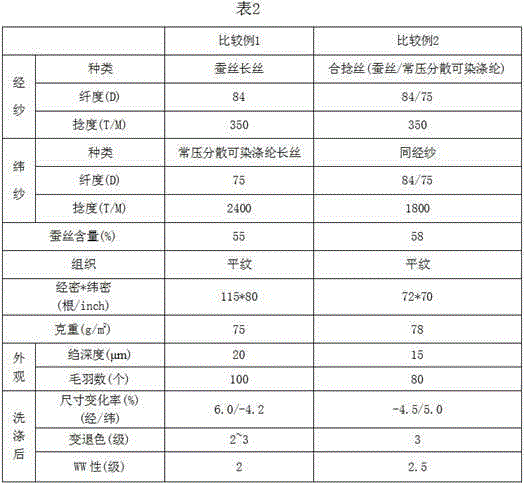

Polyester-silk crepe-de-chine woven fabric

InactiveCN106245188AComfortable to wearIncrease purchase demandWoven fabricsYarnRoom temperatureEnergy analysis

The invention discloses a polyester-silk crepe-de-chine woven fabric. The woven fabric contains silk filament yarn and room pressure-dispersed dyeable polyester filament yarn. The fabric can be dyed at room temperature and normal pressure, so that a product achieves the advantages of silk and polyester. Due to the fact that dyeing is conducted through a one bath process, little damage is caused to fibers, little hairiness is generated, the noble sense of the fabric is kept, rich colors are obtained, and maintenance is easy; meanwhile, time is saved, and consumed energy and cost are reduced. The fabric is particularly suitable for making spring and summer clothing.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

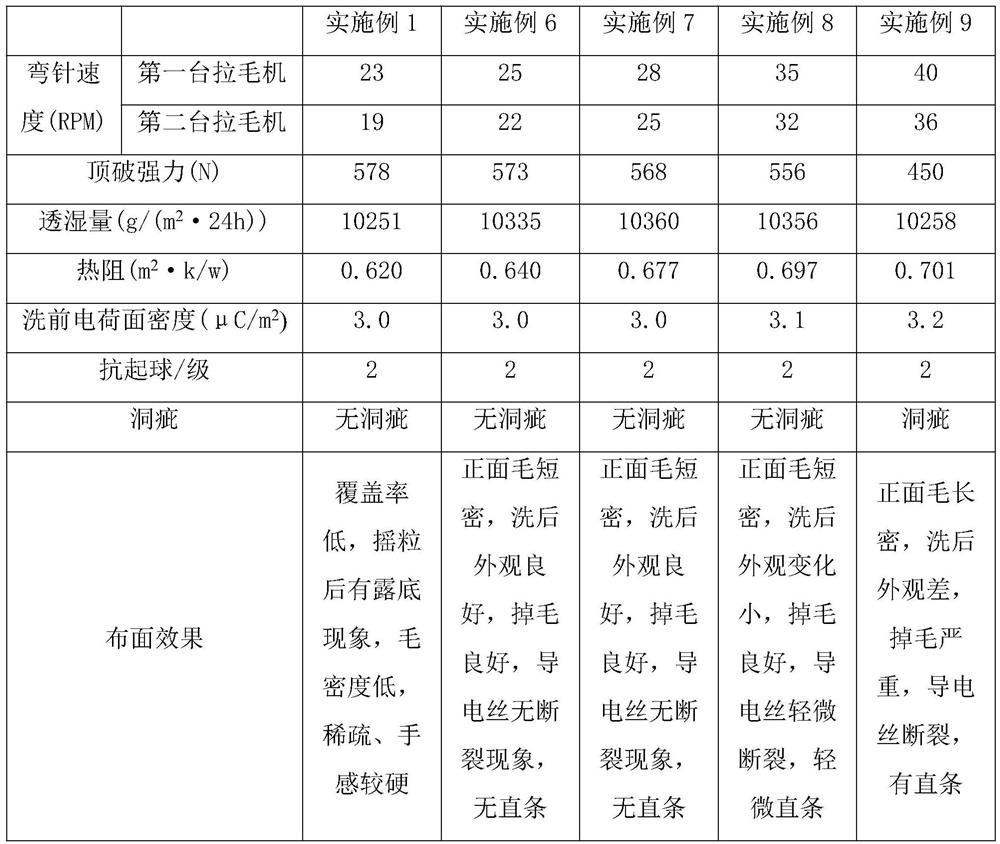

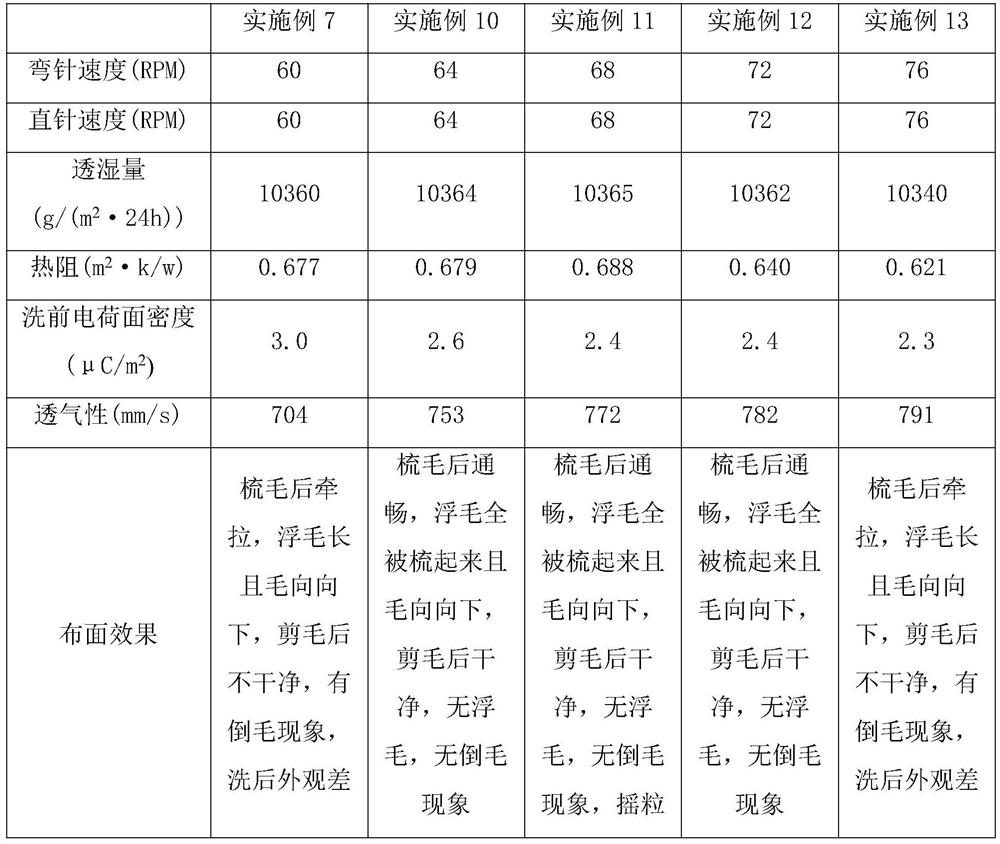

Raising method of velvet cloth and velvet cloth prepared by raising method

PendingCN113550106AImprove antistatic performanceImprove anti-pilling performanceFabric breaking/softeningGrip property fibresPolyesterYarn

The invention relates to the technical field of textiles, and particularly discloses a raising method of velvet cloth and the velvet cloth prepared by the raising method. The raising method comprises the following steps of sequentially carrying out softening and setting, napping, intermediate setting, carding, shearing, anti-pilling treatment and final setting on grey cloth to obtain the velvet cloth. The specific step of softening and setting is that the gray cloth is padded in a softening solution and is set at the temperature of 130-150 DEG C and the speed of 20-25 m / min; the gray cloth is composed of a ground weave and a looped pile weave, the ground weave is formed by interweaving 100D / 36F polyester DTY and conductive composite yarn, the looped pile weave adopts 75D / 144F polyester DTY, and the conductive composite yarn is formed by interweaving 75D / 36F polyester and 20D antistatic yarn; and the softening solution is a softening agent aqueous solution composed of a softening agent and water, and the softening agent is PEP. The PEP is adopted as the raising softening agent, so that the method is more environment-friendly, a fabric is easier to shear, and the obtained velvet cloth has excellent antistatic property and anti-pilling property.

Owner:上海嘉麟杰纺织科技有限公司

Gravimetric-method material distribution device for medium and small sized ironmaking blast furnaces and material distribution method of device

ActiveCN104388618AIncrease flexibilityAvoid material jamsBell-and-hopper arrangementBlast furnace detailsAutomatic controlEngineering

A gravimetric-method material distribution device for medium and small sized ironmaking blast furnaces and a material distribution method of the device are suitable for medium and small sized ironmaking blast furnaces about 1,000 m<3>. A pressure sensor and a pressure compensation device are additionally arranged on a material distributor; when a blast furnace charging bucket distributes material to a furnace top, the pressure in the charging bucket suddenly increases to furnace top pressure at the moment a lower sealing valve is opened, the pressure signal of the pressure compensation device is taken from the furnace top pressure, weight increase caused by pressure increase is calculated through the conversion of an automatic control system, actual weight is obtained after offset calculation, and material distribution is conducted automatically according to the actual weight; the flexibility is high, and material sticking in the charging bucket is avoided; the inclination angle of a chute is set automatically according to a material curve so as to ensure that material in the charging bucket can be discharged completely every time and cannot be accumulated; the material distribution effect is good; the production efficiency is improved.

Owner:TIANJUSHI ENG TECH GROUP +1

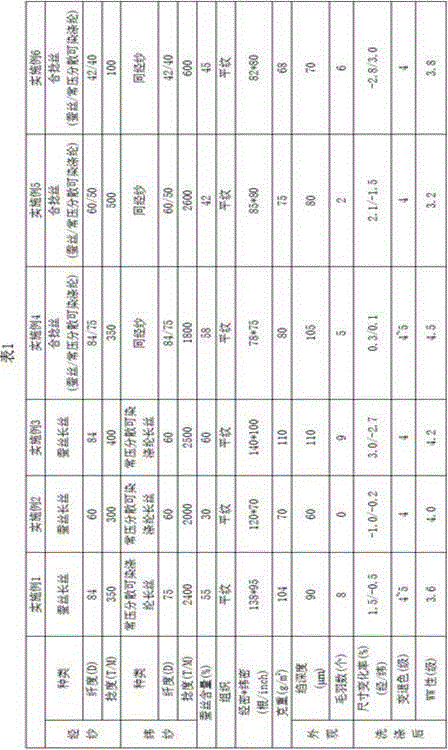

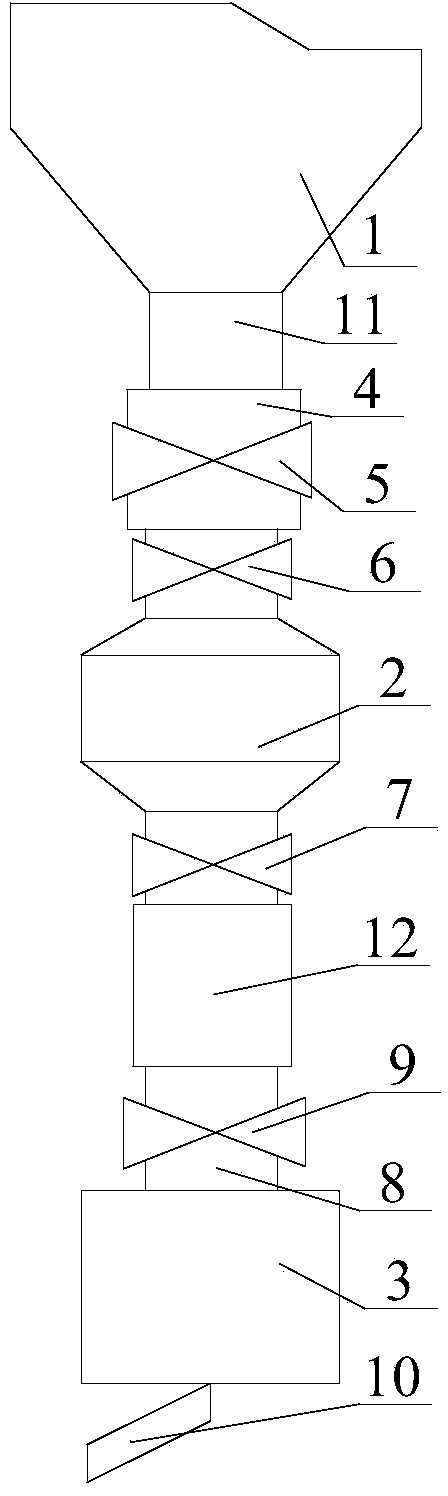

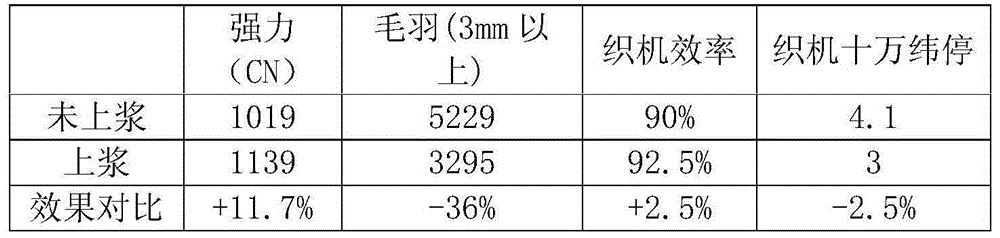

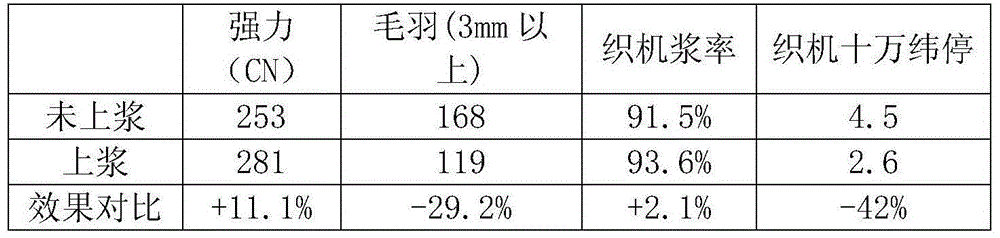

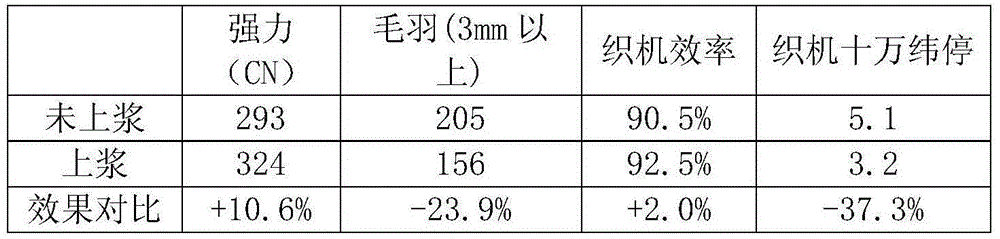

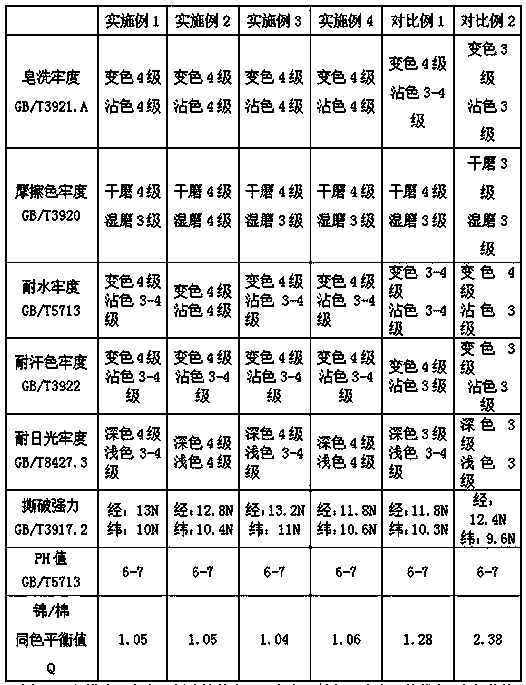

Technological method for sizing dyed weft yarns

InactiveCN105200763AImprove weaving efficiencyImprove Cloth EffectsVegetal fibresPolyvinyl alcoholEngineering

The invention provides a technological method for sizing dyed weft yarns. The technological method is characterized by sequentially comprising working procedures of normally dyeing yarns; sizing the yarns by the aid of liquid; drying the yarns. A softening procedure for dyeing the yarns includes circularly dyeing the yarns by the aid of smoothing agents for 5-10 minutes, and the working procedure for sizing the yarns by the aid of the liquid includes circularly dyeing the yarns by the aid of liquid sizing agents for 5-10 minutes; the liquid sizing agents are acrylic ester liquid sizing agents with solid contents of 25% or PVA (polyvinyl alcohol) liquid sizing agents with the concentration of 100 g / L, and a mass ratio of the liquid sizing agents to the dyed weft yarns is 20-50:1000 when the liquid sizing agents are acrylic acid sizing agents; a mass ratio of the liquid sizing agents to the dyed weft yarns is 10-20:1000 when the liquid sizing agents are the PVA sizing agents. The technological method has the advantages that the strength of the yarns treated by the aid of the technological method can be improved by approximately 10%, the hairiness of the yarns can be reduced by approximately 30%, and the weaving efficiency and fabric surface effects of woven color-spun fabrics can be greatly improved.

Owner:LUTAI TEXTILE

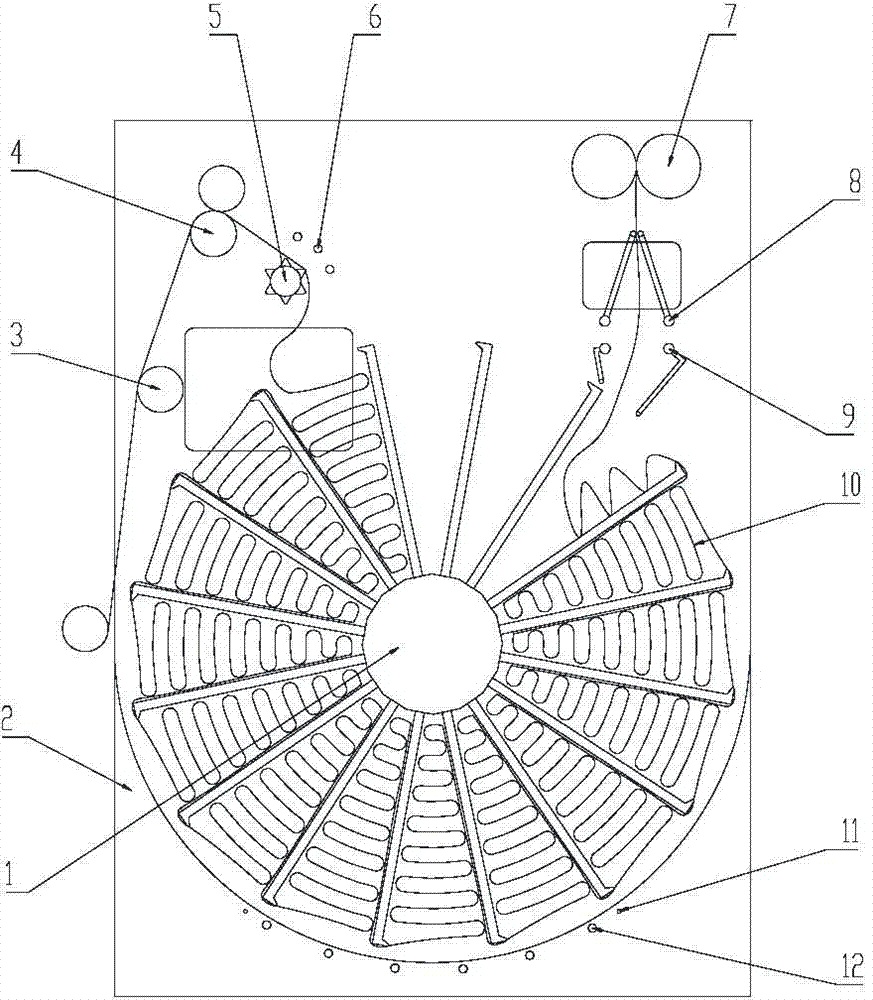

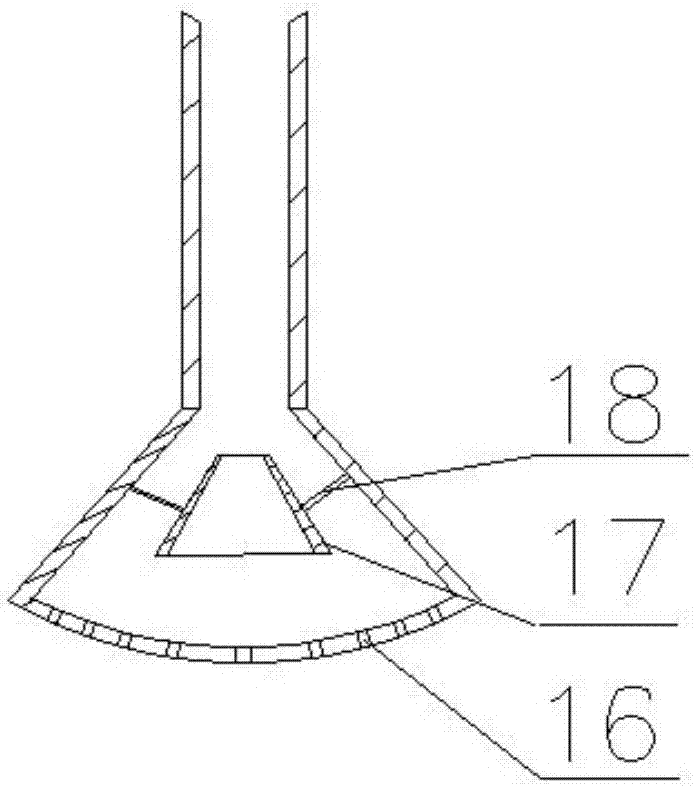

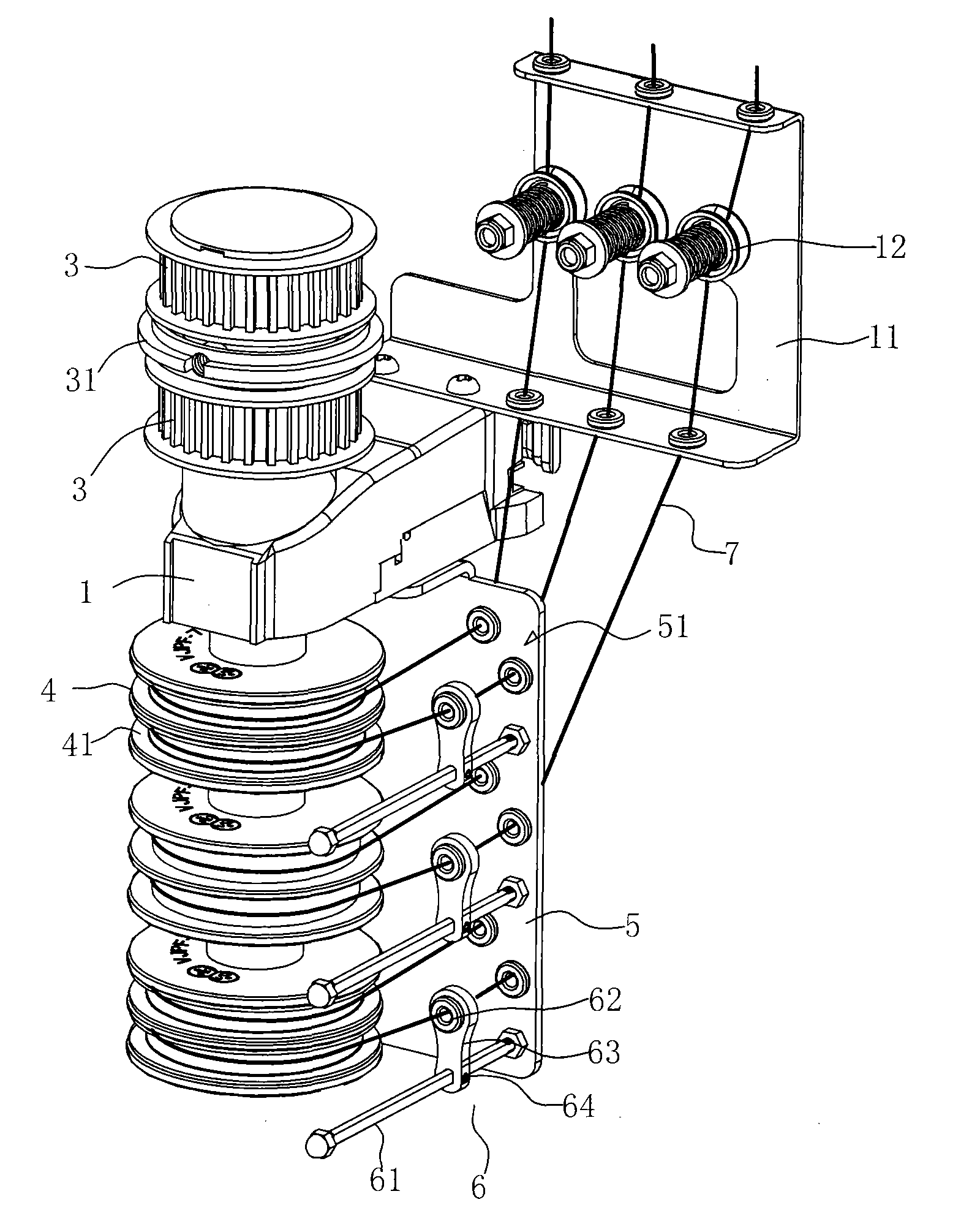

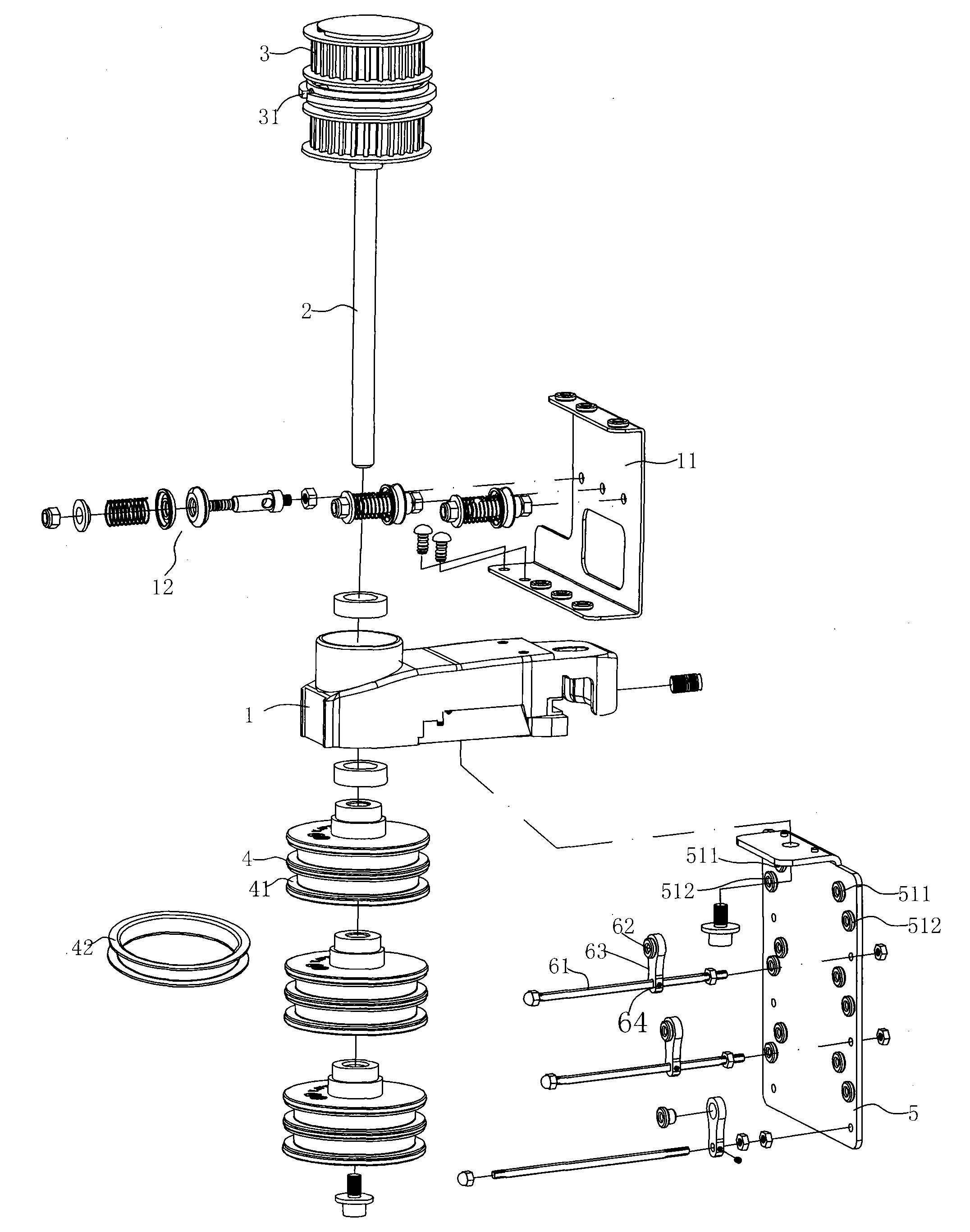

Pile fabric transfer printing device

InactiveCN103042820ASolve the problem of not vertical hairImprove Cloth EffectsTransfer printingTransfer-treating textile partsVacuum pumpingEngineering

The invention relates to a pile fabric transfer printing device which includes a cloth feeding mechanism, a printing mechanism and a winding mechanism. The printing mechanism includes a printing chamber in which a heating roller is arranged, a feeding roller is arranged along a cloth feeding direction of the heating roller and a paper delivery roller, a first draw-out roller and a second draw-out roller are arranged along a cloth draw-out direction of the heating roller. The fabrics are windingly arranged on a plurality of cloth feeding rollers, the feeding roller, the heating roller, the first draw-out roller, the second draw-out roller and the winding mechanism in sequence. Printing paper is wound round the feeding roller through a paper feeding roller, printing paper and the fabrics are wound around the heating roller together, and the printing paper is wound around a paper collecting roller through the paper delivery roller. The pile fabric transfer printing device is characterized in that a vacuum pile absorbing device is arranged on the upper portion of the printing chamber and the vacuum pile absorbing device includes vacuum pumping port, a plurality of high pressure tuyeres and water-cooling tuyeres which are arranged in sequence along a direction from the first draw-out roller to the second draw-out roller. The pile fabric transfer printing device solves the problem that piles of a cloth surface are not upright after a pile fabric is subjected to transfer printing and improves cloth surface effects after a pile fabric is subjected to transfer printing.

Owner:夏美顺

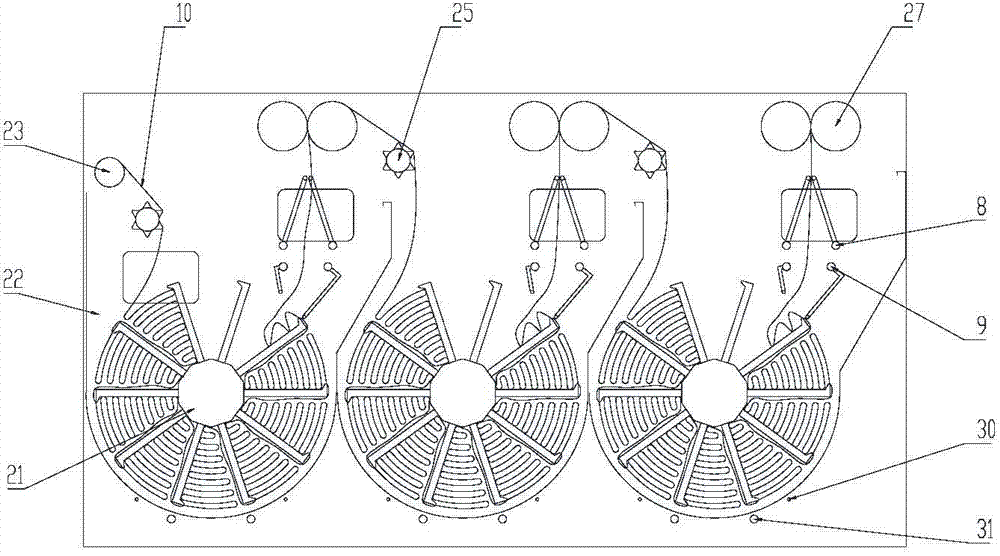

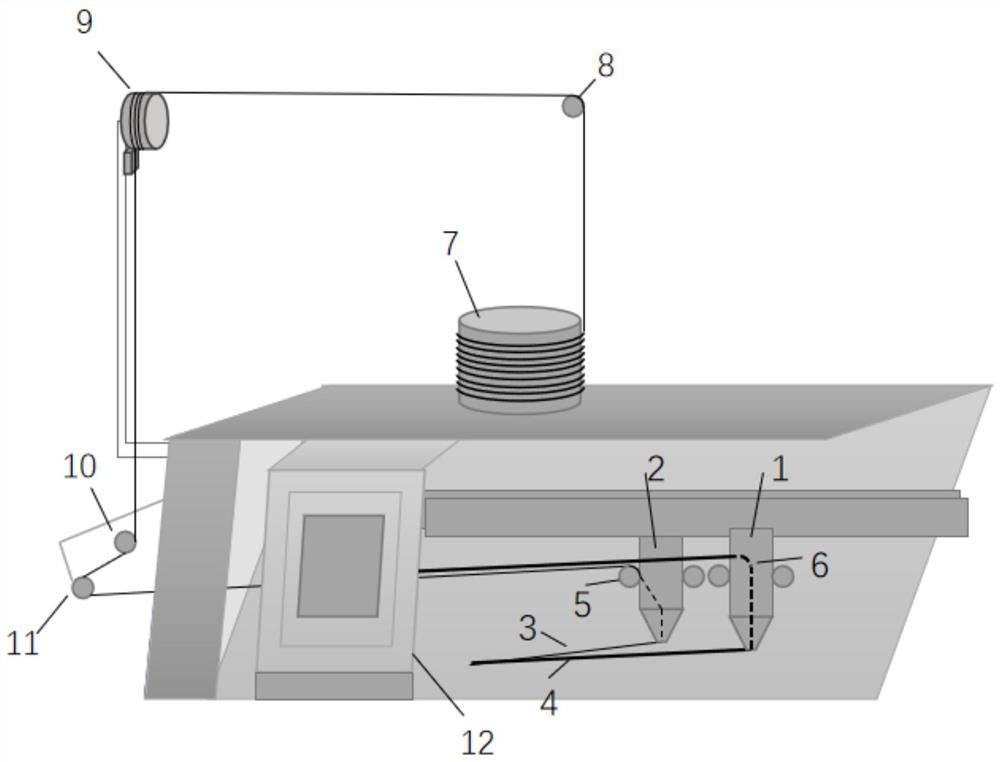

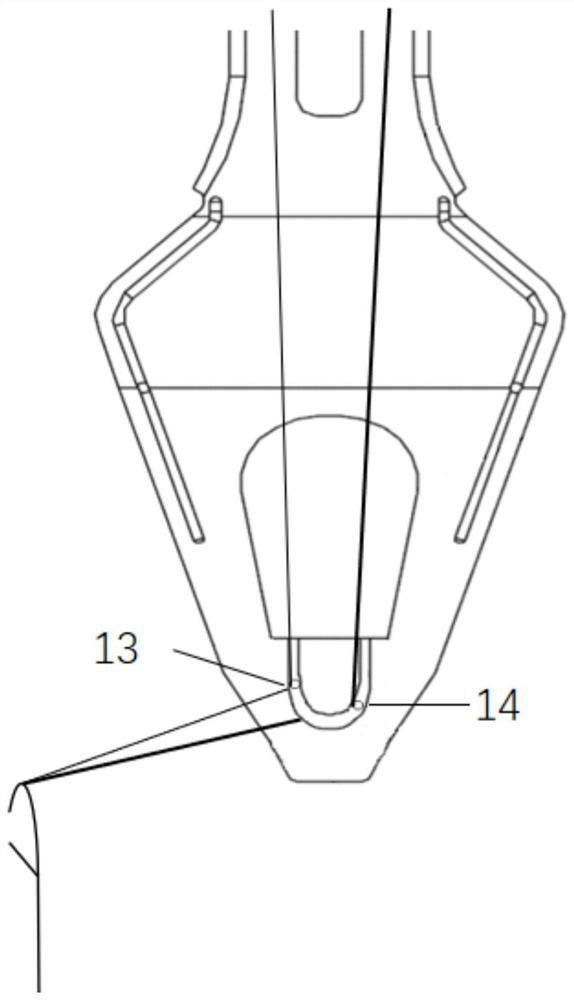

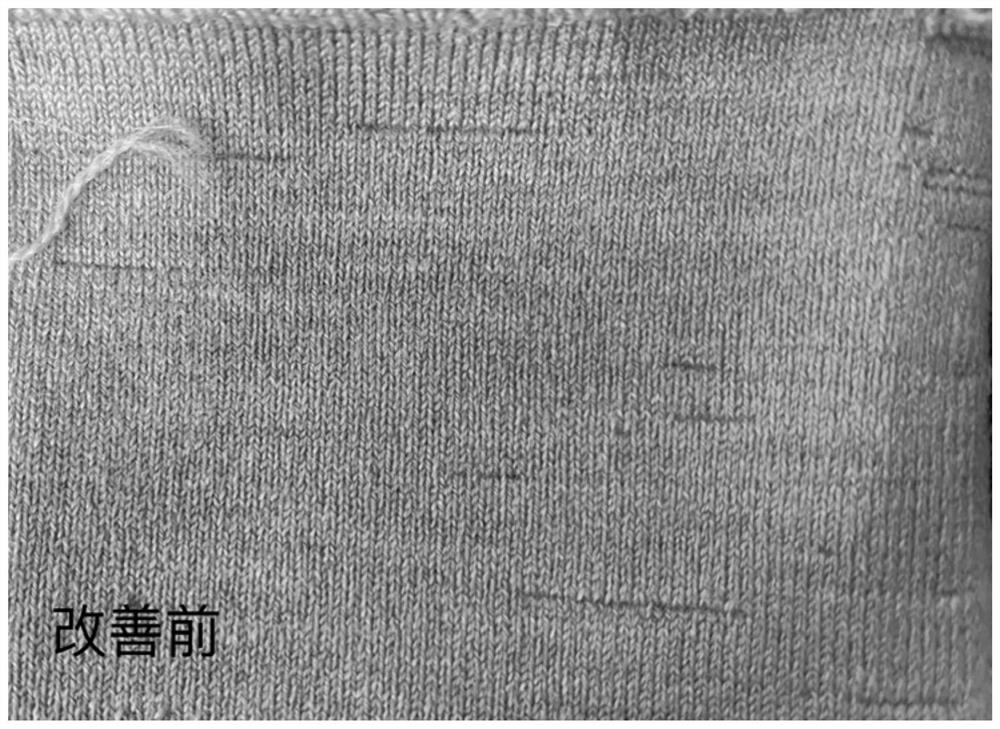

Weaving method of bare spandex yarn plated flat knitted fabric and yarn feeding device of bare spandex yarn plated flat knitted fabric

The invention discloses a weaving method of a bare spandex yarn plated flat knitted fabric and a yarn feeding device of the bare spandex yarn plated flat knitted fabric, and belongs to the technical field of textile product production. The device comprises a first yarn nozzle, a second yarn nozzle, a bare spandex yarn cylinder, a yarn guide roller, a constant tension yarn feeder, a buffer roller,a buffer arm, a flat knitting machine head and a flat knitting machine; the first yarn nozzle and the second yarn nozzle are arranged on a yarn nozzle rail of the flat knitting machine, the bare spandex yarn cylinder is arranged on a creel above the flat knitting machine head, and the buffer roller and the buffer arm are arranged on one side of the flat knitting machine head; and the constant tension yarn feeder is arranged on the upper side of the buffer roller, and the yarn guide roller is arranged on the side of the constant tension yarn feeder. According to the weaving method of the bare spandex yarn plated flat knitted fabric and the yarn feeding device of the bare spandex yarn plated flat knitted fabric, bare spandex yarn is fed into a yarn nozzle hole in the high position, and simple yarn is fed into a yarn nozzle hole in the low position, so that two yarns form relatively large difference in longitudinal angles of the inlay to ensure that the simple yarn is always exposed on the front side of the fabric in a plating structure, and the spandex yarn is always on the back side of the fabric to avoid the phenomenon of turning over the yarn and exposing the bottom.

Owner:JIANGNAN UNIV

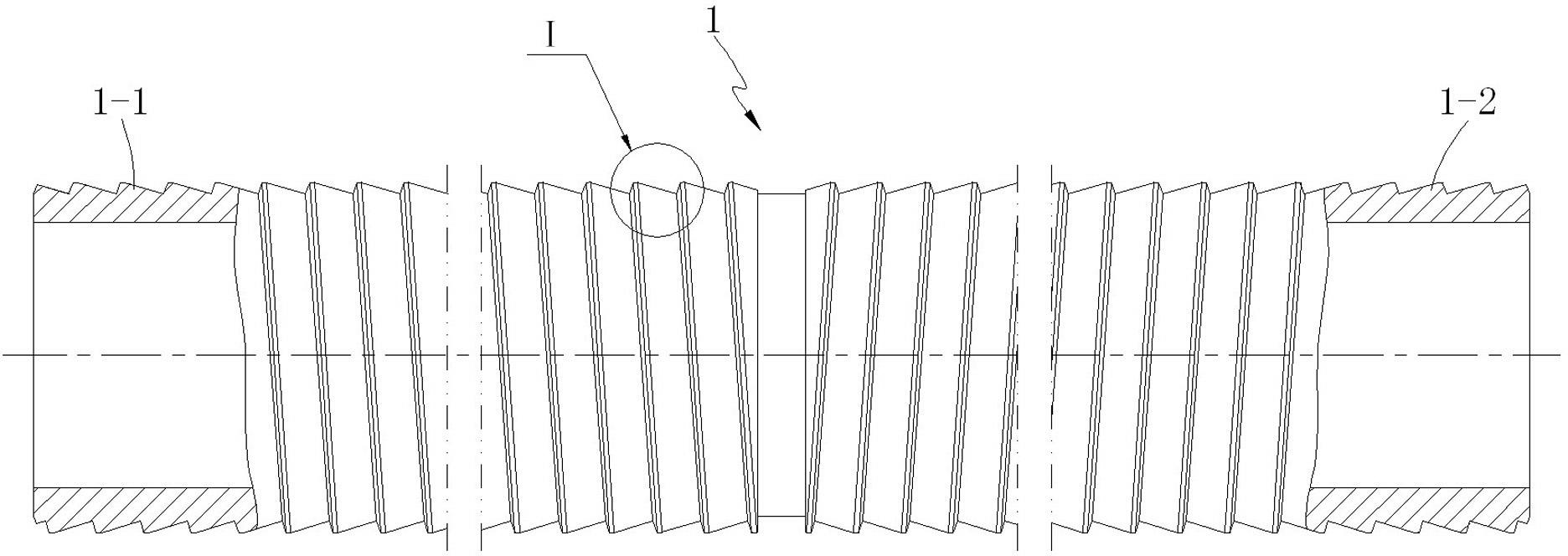

Cloth expanding device of warp knitting machine

InactiveCN102619014AEliminate austerityMeet the process requirementsWarp knittingEngineeringWarp knitting

The invention discloses a cloth expanding device of a warp knitting machine. The device comprises at least one roll shaft and wall boards, wherein the roll shaft is arranged between a warp knitting machine looping mechanism and a fabric pulling and winding mechanism; the wall boards are arranged on two sides of the roll shaft and used for rotationally supporting the roll shaft; and a right-hand sawtooth shaped thread and a left-hand sawtooth shaped thread, which are oppositely arranged on the left and right in the axis direction, are arranged at the outer circumferential surface of the roll shaft. The right-hand and left-hand sawtooth shaped threads are oppositely arranged on the left and right in the axis direction of the roll shaft and symmetrically arranged at the outer circumferential surface of the roll shaft. A pitch L between the right-hand and left-hand sawtooth shaped threads is preferably 10 mm, the tooth depth H is preferably 1.5 mm and the number of the threads is preferably 4. The cloth expanding device disclosed by the invention has the advantages of simple structure, high cloth winding quality and suitability for being promoted in the warp knitting machines; and the shrinking phenomenon of the fabric cloth after being knitted in rings can be eliminated so that the fabric satisfies the technological requirements before being wound.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

One-bath dyeing process of brocade cotton fabric

The invention relates to one-bath dyeing process of brocade cotton fabric. The process comprises the following steps: putting the brocade cotton fabric subjected to cold-dwell desizing treatment intoa dye vat, wherein a bath ratio is 1 to (5-10), adding Anoky NC type reactive dye, and sequentially adding anhydrous sodium sulphate and an alkaline agent after the reactive dye is uniformly dissolved, slowly heating up to 98-100 DEG C and carrying out heat preservation for 50-60min, then cooling and draining, sequentially washing and soaping, then washing again, and discharging the fabric. The reactive dye used in the process contains a quaternary ammonium pyridine formic acid active group, and the pH value of a dyeing bath gradually changes from alkalinity to acidity as the rise of temperature, and the dye-uptake of the dye changes along with the change of the pH; when being alkaline, the dye bath reacts with a hydroxyl group in cotton fibers, so that a covalent bond with a firm structure is formed, and cotton dyeing is further realized; when being gradually turned to be acid, the dye bath reacts with an amino group in chinlon, so that a covalent bond with a firm structure is formed,and chinlon dyeing is further realized; therefore, the brocade cotton fabric is not only good in color and cloth surface effect, but also has the fastness which is in line with customer requirements.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

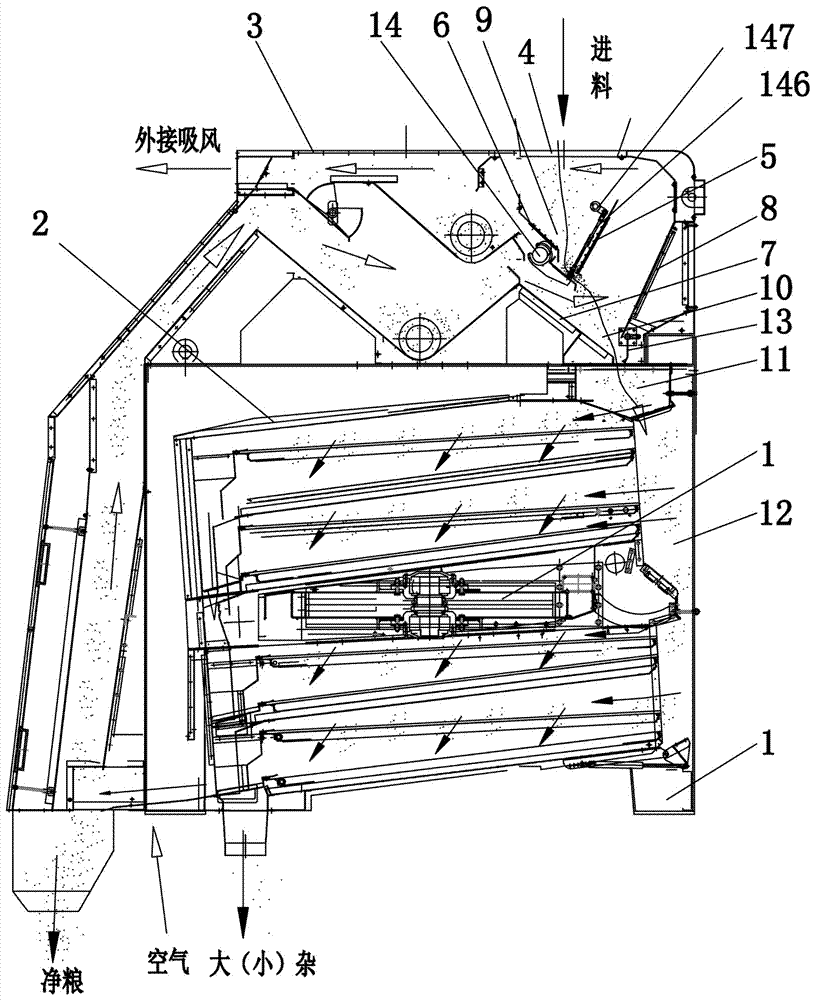

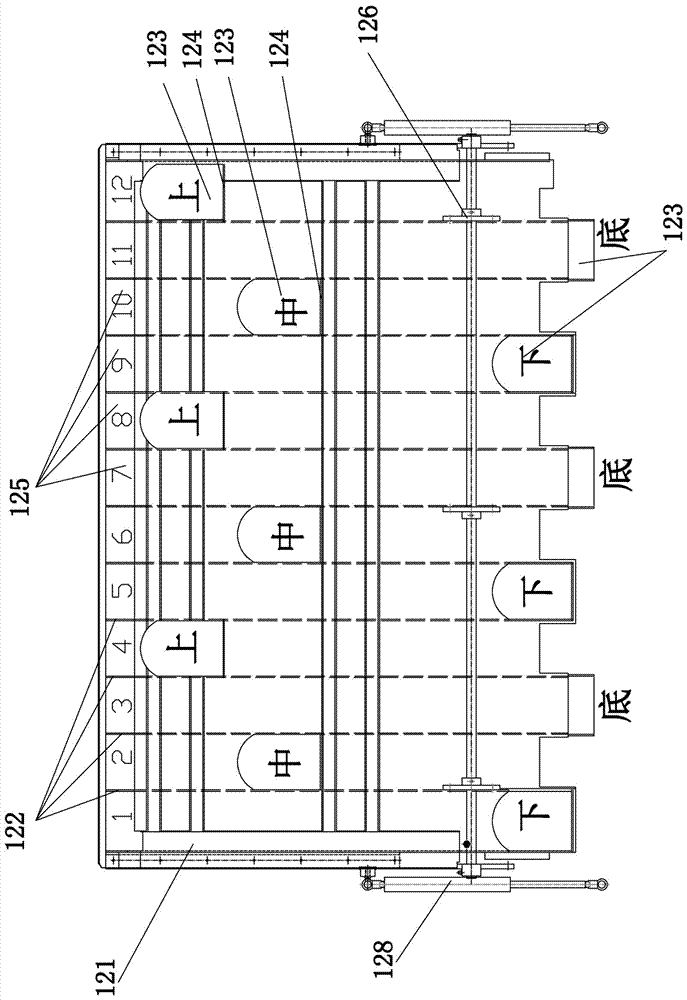

Uniform material distribution device for rotary combined multi-layer screen

ActiveCN107282395AUniform ingredientsInto the uniformSievingScreeningEngineeringMaterial distribution

The invention relates to a uniform material distribution device for a rotary combined multi-layer screen. The uniform material distribution device comprises a rack, a screen body hung on the rack, and a feeding shell at the upper end of the rack, wherein a feed inlet is formed in the feeding shell; an upper material uniformization plate and an upper material guide plate in the feeding shell form an upper feeding channel of which the section is funnel-shaped; a lower material guide plate and a lower baffle plate in the feeding shell form a lower feeding channel of which the section is funnel-shaped; an opening in the upper end of the upper feeding channel corresponds to the feed inlet; an opening in the lower end of the upper feeding channel corresponds to an opening in the upper end of the lower feeding channel; an opening in the lower end of the lower feeding channel corresponds to a feed hopper arranged on the screen body; the feed hopper communicates with a uniform material distributor arranged on the side surface of the screen body; a plurality of vertical discharge channels are arranged in the uniform material distributor; and the discharge channels communicate with different screen grids. According to the uniform material distribution device, uniform distribution of grain materials is achieved, the grain materials uniformly enter the different screen grids, the multiple layers of screen grids screen the grain materials at the same time, and screening efficiency is improved.

Owner:COFCO ENG MAOSHENG EQUIP (HENAN) CO LTD

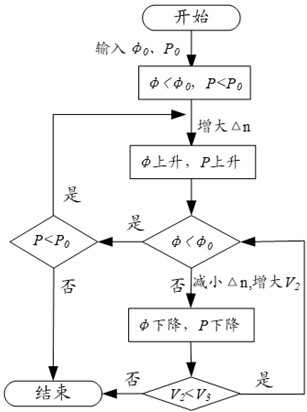

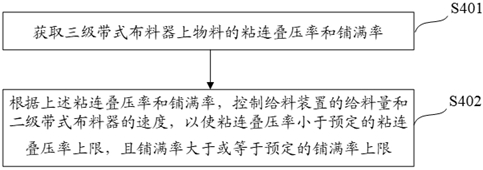

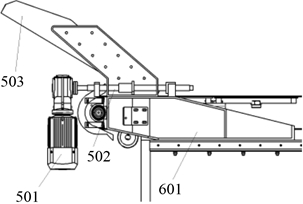

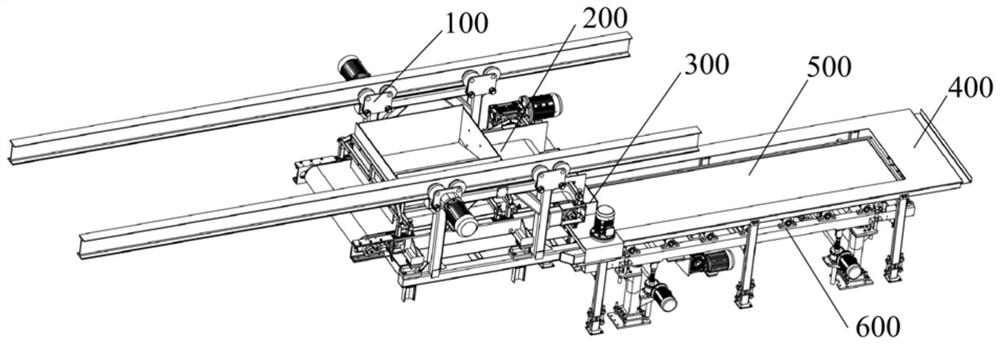

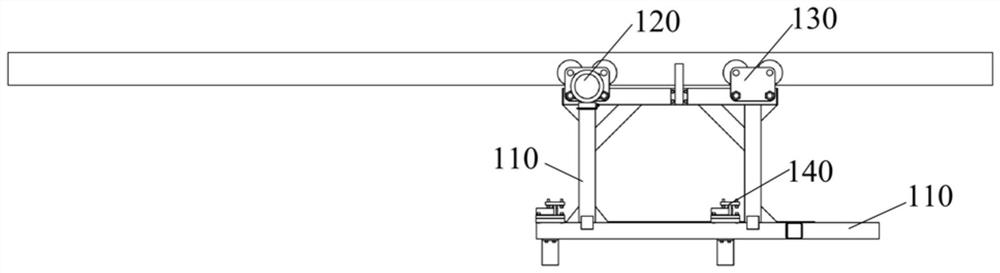

Material distribution regulation and control device and method, sorting system and computer readable storage medium

ActiveCN113023298AAchieve self-regulationImprove Cloth EffectsControl devices for conveyorsProcess engineeringSlide plate

The invention provides a material distribution regulation and control device and method, a sorting system and a computer readable storage medium, and relates to the technical field of material conveying. The material distribution regulation and control device comprises a feeding device, a first-stage sliding plate, a second-stage belt type material distributor, a material distribution sliding plate and a third-stage belt type material distributor which are connected in sequence; the device further comprises a feedback device respectively connected with the feeding device and the second-stage belt type material distributor; and the feedback device is used for obtaining the adhesion overlying rate and the full-laying rate of materials on the third-stage belt type material distributor and controlling the feeding amount of the feeding device and the speed of the second-stage belt type material distributor according to the adhesion overlying rate and the full-laying rate, so that the adhesion overlying rate is smaller than the preset upper limit of the adhesion overlying rate, and the full-laying rate is larger than or equal to the preset upper limit of the full-laying rate. According to the material distribution regulation and control device, material distribution self-adjustment is achieved through the feedback device, and compared with an existing material distribution mode based on manual adjustment, the material distribution effect is improved, and the labor cost is saved.

Owner:TIANJIN MEITENG TECH CO LTD

New nylon woven fabric woven fabric dyeing and finishing technology

InactiveCN105002759AGood acid and alkali resistanceEasy to refineDry-cleaning apparatus for textilesDyeing processWater bathsYarn

The invention relates to a new nylon woven fabric woven fabric dyeing and finishing technology, especially relates to a new nylon woven fabric woven fabric desizing and dyeing one-bath technology, and relates to the field of textile dyeing and finishing. The technology comprises the following steps: putting a dye and a woven fabric grey cloth in a water bath at room temperature, and adding an anionic desizing agent accounting for 1-4% of the weight of the woven fabric grey cloth, a yarn split resistance agent accounting for 1-2% of the weight of the woven fabric grey cloth and a cationic / nonionic surfactant accounting for 1-3% of the weight of the woven fabric grey cloth into the water bath; heating the water bath to 85DEG C, maintaining the temperature for 10min, and adding acetate acid gracial accounting for 0.2-0.5% of the weight of the woven fabric grey cloth; and heating the water bath heating to 105DEG C, maintaining the temperature for 40min, and cooling the water bath to 80DEG C in order to complete the desizing and dyeing one-bath technology. Compared with present desizing and dyeing two-bath technologies, the technology provided by the invention has the advantages of reduction of about 50% of the water consumption and the sewage discharge capacity per 10000yds of cloth, saving of about 50% of the sewage discharge cost per 10000yds of cloth, shortening of about 40-50% of the dyeing process flow time per cylinder of cloth, increase of about 80-90% of the output under same equipment, saving of about 30-40% of coal per 10000yds of cloth, saving of about 40-50% of the power consumption per 10000yds of cloth, and reduction of about 200yuan of the labor force cost per 10000yds of cloth.

Owner:金生智

Artificial stone sheet material distributing system and method

The invention discloses an artificial stone sheet material distributing system. The artificial stone sheet material distributing system comprises a guide rail, at least one material distributing device and at least one material distributing station. The material distributing devices are arranged above the material distributing stations. The material distributing devices comprise translation devices, and material storage belt conveyors and material distributors which are arranged below the translation devices. The material distributing stations comprise sheet molds, lifting conveying tables arranged below the sheet molds and trays arranged between the sheet molds and the lifting conveying tables. In the material distributing process, the translation devices drive the material storage belt conveyors and the material distributors to do translation motion above the material distributing stations, the height of the sheet molds is kept unchanged, and the lifting conveying tables drive the trays to do lifting motion so as to receive materials distributed by the material distributors. Correspondingly, the invention further discloses an artificial stone sheet material distributing method. By implementing the artificial stone sheet material distributing system and method, the material storage belt conveyors, the material distributors and the material distributing stations can be separated through the translation devices, the structure of the material distributing stations is simplified, and the service life of the material distributing stations is prolonged.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Production method of four-face elastic nylon fabric

InactiveCN111663227AInhibition of contractionSuppresses wrinkling of protrusionsWoven fabricsYarnFiber

The invention discloses a production method of four-face elastic nylon fabric. The method comprises the following steps that nylon full-draft filament serves as warp after being subjected to warping,and nylon semi-draft filament and spandex fiber are twisted to serve as weft; the warp is sequentially subjected to warping, slashing, beaming and drafting and then fed to a textile machine fiber shaft; weft is subjected to high-elastic false twist processing to obtain high-elastic yarn; and technological parameters of a textile machine are set, and the high-elastic yarn is orthographic and solidified to form the four-face elastic nylon fabric. According to the method, by reasonably designing the fabric overall coverage coefficient, good fabric elasticity and the good cloth cover effect can beobtained.

Owner:吴江市双盈化纺实业有限公司

Method for processing no-iron 100% bombast

ActiveCN100404750CGood flexibilityDimensionally stableBiochemical fibre treatmentVegetal fibresYarnAfter treatment

The present invention discloses a processing method of all-flax flexible self-smoothing face fabric. It is characterized by adding the processes of tensionless desizing and enzyme treatment in the face fabric finishing stage, and its whole processing method includes the following several steps: loosening yarn, pretreatment, dyeing, after-treatment, coning, weaving, gray inspection, singeing, tensionless desizing, enzyme treatment, liquid ammonia finishing, finalizing design and re-shrinking.

Yarn conveying device of knitting loom

The invention discloses a yarn conveying device of a knitting loom. A yarn through plate is fixed on a fixed seat of the yarn conveying device, the yarn through plate is vertically arranged beside a yarn conveying wheels, and the different height positions of the yarn through plate are provided with yarn guide porcelain holes corresponding to different yarn conveying wheels respectively; a tension adjustor is arranged on the yarn through plate; during working, the yarn guide porcelain holes on the yarn through plate are positioned at proper positions of two sides of the yarn conveying wheels;and when yarns are wound on the yarn conveying wheels for the second circle, the yarns pass through the tension adjustor through the yarn guide porcelain holes on the outer side. The tension adjustorcan be adjusted according to the performance of the yarns, so that the contact friction face of the two yarns and the yarn conveying wheels is increased or reduced, and the tension of the yarns is adjusted. Therefore, when the different yarns are knitted into secondary color stripe cloth by using the same yarn conveyor, the cloth surface effect is better, the yarns are conveyed more smoothly, theknitted yarn length is more stable, and the cloth surface is clearer.

Owner:韦增机械(佛山高明)有限公司

Cotton fabric reactive dye cold pad-batch dyeing process

InactiveCN110607626AHigh color fastnessGood salt consumptionSucessive textile treatmentsChemical fixing of textilesRoom temperatureEngineering

The invention provides a cotton fabric reactive dye cold pad-batch dyeing process. The cotton fabric reactive dye cold pad-batch dyeing process comprises the following steps: (1) preparing dye liquorand alkali liquor, (2) padding a fabric, (3) rolling, (4) stacking and fixing the color, (5) washing with water, (6) soaping, and (7) drying. Cold pad-batch dyeing is a semi-continuous dyeing process,and after the fabric is padded with the dye liquor containing reactive dye, an alkali agent and other auxiliary agents, the fabric is rolled and stacked for a period of time at room temperature to complete adsorption, diffusion and fixation of the dye; and the dyeing process is excellent in dyeing fastness, good in leveling property and reproducibility, and less in saline-alkali consumption, andwater consumption and sewage discharge are also greatly reduced.

Owner:HANGZHOU TIANRUI DYEING PRINTING

Dyeing method of polyester, acrylic, viscose and spandex blended fabrics

The invention discloses a dyeing method of a terylene, acrylic fiber, viscose glue and spandex blended fabric. The method comprises the following steps: 1, blended fabric weaving: weaving a blended fabric containing terylene, acrylic fiber, viscose glue and spandex; 2, blended fabric treatment: carrying out scotching presetting on a gray cloth, and linking; 3, carrying out one-bath dyeing on terylene and acrylic fibers; 4, reducing, neutralizing, and washing with water; 5, carrying out two-bath dyeing on the viscose glue; 6, washing with water, neutralizing soaping, washing with water, and discharging the obtained cloth; and 7, post-treatment: dehydrating the blended fabric obtained in step 6, drying, and carrying out scotching setting to obtain a finished product. The method has the advantages of simple process, fastness, efficiency, energy saving, convenient operation, stability, and dyeing of high-quality and stable-product-quality terylene, acrylic fiber, viscose glue and spandex blended fabrics.

Owner:GAOMI FUYUAN PRINTING & DYEING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com